11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h

As a professional textured vegetable TVP line manufacturer, our double screw extruded soya protein making machine design good manufacturing process. Texture soya protein food making machinery can take corn flour, wheat flour, and others as raw materials, to make the high nutrition soya chunks food for sales.

11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h Specifications :

| Price | Contact Us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Type | soybean protein machine, soya nuggets plant |

| Warranty | 1 YEAR |

| Certification | CE ISO9001 |

| Capacity | 120-150kg/h,200-300kg/h,500-800kg/h |

| Material: | Stainless Steel 304 |

| Automation | Fully Automatic |

11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h Detail Introduction :

Soya meat /soya nuggets processing line is the newest botanical protein food processing line which is developed independently according to our national conditions on the requirement of market and on the base of advanced machinery in Switzerland and America .

This processing line uses soybean power and peanut powder to break spherical protein molecule to form chain protein molecule thus creating slice-like fiber structure, by powder-grinding, stirring, high-temperature, high-pressure and high-cutting. The product is nutritious without cholesterol or animal fat, but it looks like and tastes like meat with the quality of absorbing soil , water, and flavor.

Product parameters of Soya Meat Making Machine:

| Applicable Industries: | 11-20kw Automatically Textured Vegetable Protein TVP Line Machine 600-1000kg/h |

| Converter: | Customizable |

| Capacity: | 100-150g/h 200-250kg/h 300-500kg/h 300-500kg/h |

| Certification: | CE,ISO9001 |

| Model: | LY65 LY70 LY85 LY75 LY95 |

| Voltage: | customizable |

| Equipment Material: | 304 Stainless Steel |

| Service | Long Service Life |

| Raw material | corn flour,wheat flour and other grain flour |

| Soybean Protein Production Line | |||

| Model Parameter | LY65 processing line | LY85 processing line | LY90 Processing Line |

| Installed power | around 100KW | around 160KW | around 200KW |

| Consumption | 70KW/H | 120KW/H | 160KW/H |

| Output | 200-250kg/h | 350-500KG/H | 500-800KG/H |

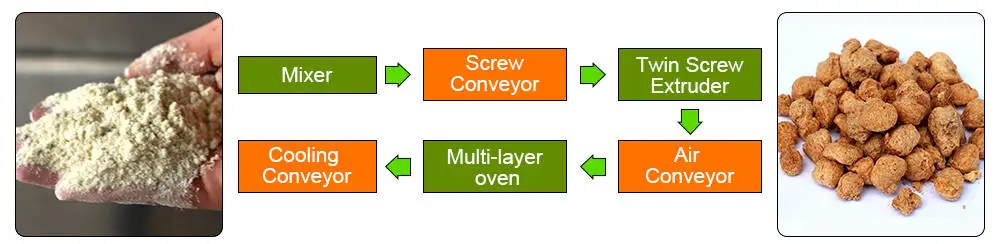

Flow Chart OF Soya Meat Making Machine

Mixer-Screw Conveyor-Twin Screw Extruder- Air Conveyor- Dryer- Hoister- Flavoring Machine

The Main Equipment Using In The Soya Bean Meat Protein Making Machine

| 1. | Flour Mixer | Mixing various flour ingredients and water evenly. |

| 2 | SCREW CONVEYOR | Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder. |

| 3 | DOUBLE SCREW EXTRUDER | Series of double-screw extruder mainly consist of feeding system, extruding system, cutting system, heating system, lubricating system and controlling system.Automatic lubricating and forced cooling make sure that extruder performs safely and extends using life.Feeding system, extruding system and cutting system all adopt frequency conversion timing to gain powerful drive, stable perform, and electricity saving. |

| 4. | Air conveyor | Take the extruded products into oven or drying |

| 5. | DRYER | It can be used to bake and dry the food. The oven can bake all kinds of the inflating food, pet food, TVP/TSP food, peanut, nut, chew nut and so on. |

| 6. | Cooling convyor | Be used to cool products |

Machine Feature OF Soya Meat Making Machine

| 1. | Simple structure in linear type ,easy in installation and maintain. |

| 2. | Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. |

| 3. | High pressure double crank to control the die opening and closing. |

| 4. | Running in a high automation and intellectualism, no pollution |

| 5. | Apply a linker to connect with the air conveyor ,which can directly inline with filling machine . |

Applications Of Automatic Soya Bean Meat Protein Food Production Line

Dry Textured soya protein Pellets, Crumbs, Minced, Flakes, Chunks, Chips ,Schnitzel, Nuggets.

High moisture wet protein Soya,pea, Pea-sunflower

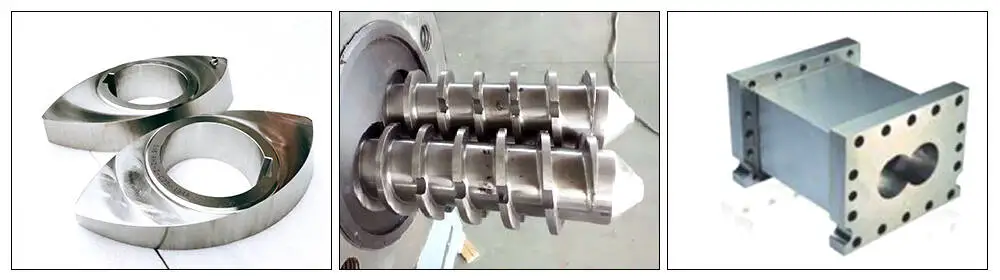

Machine Details Photos Of Soya Bean Meat Protein Food Production Line

Double screw extruder---- the main machine to make soya protein. It is used to extrude and inflate material and then form it into different shapes. According to different screw design rate to full different technology request.

What are the details of theTextured Vegetable Protein TVP Line Machine?

| 1. | Alloy (38CrMoAL) screw made by nit-riding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. |

| 2. | Adopting speed adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process. |

| 3. | Gearbox with automatic lubrication function, extending gear life. |

| 4. | World famous brand Siemens main motor, guaranteeing good quality |

| 5. | Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely. |

| 6. | Cutting knife fix ed in the die head seat, rotary cutting by V-belt drive. |

Package&Delivery

1.Packaging Specification

Outside Package: Wooden Packing as Export and Standard.

Inner Package: Stretch Film

2.Delivery time

5-10days after received 40% of the whole payment.

3.About Shipping

We can be responsible for the shipping,of course,we can also accept and cooperate with your agent if you have shipping forwarder in China

Our Service

We provide Professional After sale service:

| 1. | Allocation chart as the buyer's request will be supplied. |

| 2. | Operation manual will be supplied after shipment. |

| 3. | One year w arrantee, life time maintenance with cost price. |

| 4. | Free easy broken spare parts will be sent with container . |

| 5. | First installation can be done by engineer. |

| 6. | Training workers in customer's factory. |