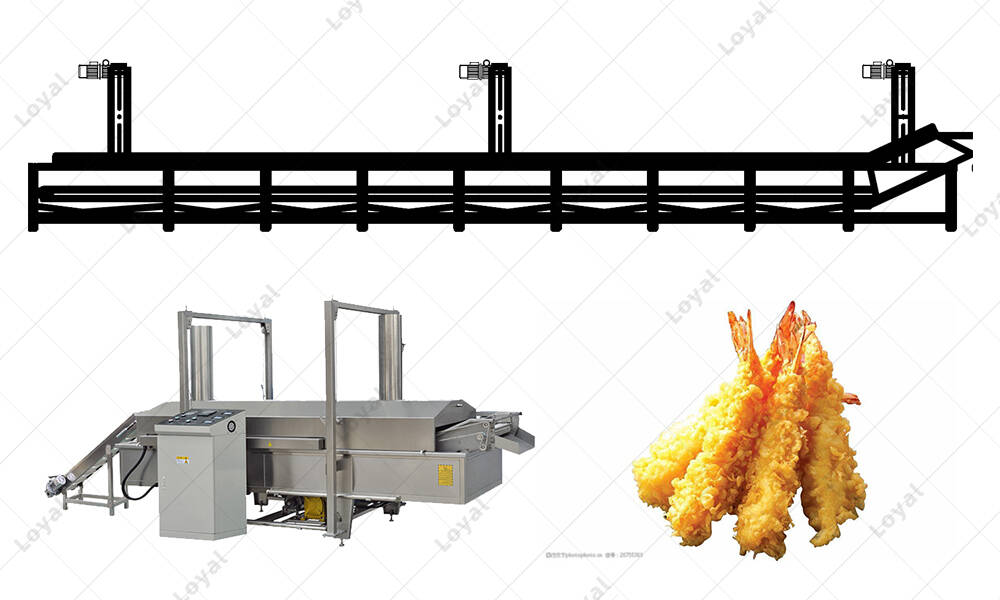

Fully Automatic Tempura Shrimp deep fryer machine

Now Tempura Shrimp have become the first choice of snacks for the public, and almost every class of people likes Tempura Shrimp, so the Tempura Shrimp market has a bright future. If you also want to get a better development in the Tempura Shrimp industry, loyal tempura shrimp frying machine will be your ideal choice.

Shandong loyal has established a complete service system for tempura shrimp frying machine, providing manufacturers with high-quality and low-cost tempura shrimp frying machine, and at the same time providing complete after-sales service of tempura shrimp frying machine, so that you have no worries in the tempura shrimp industry.

Fully Automatic Tempura Shrimp deep fryer machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Model Number | Automatic Tempura Shrimp deep fryer manufacturing equipment |

| Min.Order Quantity | 1set of Automatic Tempura Shrimp deep fryer machine |

| Payment Terms | D/A,D/P |

| Supply Ability | 25Days of Tempura Shrimp deep fryer machine |

| Team | Professional Fryer Technology Team |

| Sale Team | Fryer Machine Technical Team |

| Technology | 8 Years Of Fryer Technology |

Fully Automatic Tempura Shrimp deep fryer machine Detail Introduction :

How To Choose Tempura Shrimp deep fryer machine Of Different Models ?

The Mold Of Gas/Diesel Fryer Continuous Tempura Shrimp Frying Machine | ||||

Model | Electric (Gas/Diesel) Consumption | Output | Heating Temperature | Dimensions |

Ly-L | 60kw | 300kg/h | 250°C | 3000x1200x2100mm |

Ly-Lii | 96kw | 400-500kg/h | 250°C | 4000x1300x2200mm |

Ly-Lg |

| 300kg/h | 250°C | 3000x1200x2100mm |

Ly-Lgii | 35m8/h(Gas) 8-41 Kg/h(Diesel) | 400-500kg/h | 250°C | 4000x1300x2200mm |

Ly-S | 45kw | 60-80kg/h | 250°C | 2000x1500x2100mm |

What Is a Continuous Fryer?

The electric batch fryer nuts cashew frying machine is a large frying machine with mesh belt structure. Electric batch fryer nuts have the advantages of large output and convenient operation, and are widely used in cashew frying machines and electric batch fryer processing lines. In addition, all parts of the electric batch fryer are made of 304 stainless steel.

Application for Tempura Shrimp deep fryer machine

Continuous fryer is mainly suitable for larger food production enterprises, and the applicable products include: Broad beans, green beans, peanuts and other nuts; puffed food such as rice cakes and potato chips; rice noodles, cat ears,, twist and other flour products; meat products such as meat pieces and chicken legs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and bean curd, etc.

Technical Parameters And Price Of Continuous Fryer Tempura Shrimp deep fryer machine

Technical Parameters And Price Of Continuous Fryer Tempura Shrimp Frying Machine | |||

Type: | Drying Oven | Application: | Fryer machine |

Condition: | New | Place Of Origin: | Shandong, China |

Brand Name: | LY | Voltage: | 380v/440v Customized |

Power: | 20-200kw | Dimension(L*W*H): | 8640 *1200* 2200mm |

Key Selling Points: | High Productivity | Warranty: | 1 Year |

Applicable Industries: | Food & Beverage Factory, Farms, Food & Beverage Shops | Marketing Type: | Ordinary Product |

Machinery Test Report: | Provided | Core Components: | Motor, Plc |

Motor Brand: | Abb | Product Name: | Microwave Grains Dryer |

The Layout of Tempura Shrimp deep fryer machine

Automatic Continuous Frying Machine is made of food grade stainless steel, consists of lifting system, conveying system, gas heating system, blowdown system, oil circulation system, smoke exhaust system and electric control system.

Features&Advantages of Continuous Fryer Tempura Shrimp deep fryer machine:

Features&Advantages of Continuous Fryer Tempura Shrimp deep fryer machine | |

1. | Frying machine is suitable for continuous food production with high output. |

2. | The products are layered between upper and lower mesh belt so as to avoid floating when they are fried in frying oil. |

3. | The transmission system of the frying machine is designed as frequency stepless speed regulation, this can help the operator to control the frying time freely. |

4. | The equipment is equipped with automatic lifting system, help the mesh belt to be cleaned more easily. |

5. | Automatic scraping system can continuously take away the oil residue produced in the frying process from the bottom, this can keep the frying oil clean and extend the service life of frying oil. |

6. | Multi group temperature control system, can save more electricity consumption. |

7. | Unique temperature control panel, make operating easy, simple and safe. |

Which Market Did The Loyal Industrial Continuous Fryer Tempura Shrimp deep fryer machine?

Customer Have Formula Request Of Continuous Fryer Tempura Shrimp deep fryer machine Manufacturers | |

1 | China 300t/Year Continuous Continuous Fryer Tempura Shrimp Machine |

2 | 200/H PLC Control Continuous Fryer Tempura Shrimp Machine For Sale In Puerto Rico |

3 | 300/H Industrial C Continuous Fryer electric deep fryer machine tempura Shrimp For Sale In Bolivia |

4 | 800Kg/H electric deep fryer machine tempura Shrimp For Sale In Argentina |

5 | 100/H Fully Automatic Industrial Continuous Tempura Shrimp Fryer For Sale In Benin |

6 | 500/H PLC Control Fully Automatic Industrial Tempura Shrimp fryer machine commercial For Sale In British Indian Ocean Territory |

7 | 200/H PLC Control Fully Automatic Industrial Continuous gas deep fryer machine Tempura Shrimp For Sale In Chile |

Cooperated Customer For Laboratory Machine Of Plc Control Continuous Fryer Tempura Shrimp Machine | |

1 | Senegal 200Kg/H Industrial Continuous shrimp tempura frying machine |

2 | 100-200Kg/H Industrial Continuous Tempura Shrimp Fryer For Sale In Côte d'Ivoire |

3 | 300-400Kg/H Industrial Tempura shrimp batch frying machine For Sale In Sold In Russia |

4 | 500Kg/H Industrial Continuous Tempura Shrimp Fryer For Sale In Sold In Denmark |

5 | 600Kg/H Plc Control Crispy Shrimp Tempura Recipe For Sale In Dominica |

6 | 100-200Kg/H Industrial Continuous Recipes with tempura shrimp For Sale In Egypt |

7 | 300-400Kg/H Industrial Continuous Tempura Shrimp Fryer For Sale In Sold In Ethiopia |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 300Kg/H PLC Control Continuous Dough Snack Fryer For Sale In Uzbekistan |

2 | 100kg/h Industrial Fully Automatic Pasta Processing Line For Sale In Senegal |

3 | Mozambique 400Kgt/H Fully Automatic Pasta Processing Line |

4 | 200Kg/H Thai PLC Control Continuous Dough Snack Fryers |

5 | Uzbekistan 100kg/H PLC Control Continuous Dough Snack Fryer |

6 | 500kg/H Fully Automatic Pasta Processing Line For Sale In Germany |

7 | 200kg/H Fully Automatic Pasta Processing Line For Sale In Guinea |

Cooperated Customer With Fully Automatic Tempura Shrimp Line Technology At 2021 | |

1 | Nigeria 500Kg/H Fully Automatic Tempura Shrimp Line |

2 | Austria Sells Fully Automatic Industrial Continuous Dough Snack Fryers 1000kg/h |

3 | Industrial Continuous Tempura Shrimp Fryer For Sale In Pakistan 100kg/h |

4 | 100Kg/H Fully Automatic Industrial Continuous Dough Snack Fryers Line For Sale In India |

5 | 200Kg/H Industrial Continuous Tempura Shrimp oil fryer machine For Sale In Israel |

6 | 200Kg/H Plc Control Continuous Tempura Shrimp oil fryer machine For Sale In Jamaica |

7 | 200Kg/H Plc Control Continuous Dough Snack Fryer For Sale In Morocco |