Wafer Biscuits Making Machines

As one professional wafer Biscuits machine manufacturer,we can offer small, medium and large automatic wafer biscuit production line for sale. The wafer Biscuit production line has reasonable price, reliable quality and professional service!Our company provides customers full set service .Cost accounting,biscuit design, biscuit recipes, machine installation and debugging, design Wafer Biscuits Making Machine molds according to customer requirements.

Wafer Biscuits Making Machines Specifications :

| Brand Name | LOYAL |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T |

| Delivery Detail | 30days /Chocolate Wafer Making Machine |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

Wafer Biscuits Making Machines Detail Introduction :

As one professional wafer Biscuits machine manufacturer,we can offer small, medium and large automatic wafer biscuit production line for sale. The wafer Biscuit production line has reasonable price, reliable quality and professional service!Our company provides customers full set service .Cost accounting,biscuit design, biscuit recipes, machine installation and debugging, design Wafer Biscuits Making Machine molds according to customer requirements.

The wafer production line uses a door type sheet cooling machine, which has the characteristics of aesthetics, increased number of cooling sheets, convenient access for staff, and the addition of a vertical freezer and refrigeration system to better improve the temperature, humidity of wafer biscuits, improving quality and taste of wafer bisuits, kind of standard type of wafering equipment. This production line is suitable for small and medium-sized enterprises, independent vendors, and new developers who have certain requirements for production. Investors can also choose according to their own sales and production requirements.

Wafer biscuits making machines are machines specially designed for use in the provision of wafer biscuits which are a very common type of biscuits used for both snacks and meals substitute in several parts of the world. Akways needed in the provision of foods and sweet items, the focus of this essay is on the way these machines are operated in a quality and efficiency oriented perspective.

Technical Parameters And Price Of Wafer Biscuits Making Machine

| Technical Parameters And Price Of Wafer Biscuits Making Machine | |||

| Model NO.: | LY-CF4 | Packaging Technology: | Mildew Proof Packaging |

| Circulation Function: | Single Packing | Frequency of Use: | Packing |

| Mode of Operation: | Packaging of Export Products | Packing Material: | OPP/CPR PT/PE, Kop/CPR Alu-Foil |

| Packaging Type: | Bags, Film | Packing Speed: | 50-200bag/Min(One Lane) |

| Main Function: | Feeding and Packing Line | Certificate: | Ce |

Transport Package: : | Wood Case | Specification: | 9500*7500*1500 |

| Trademark: | TEFUDE | Origin: | China |

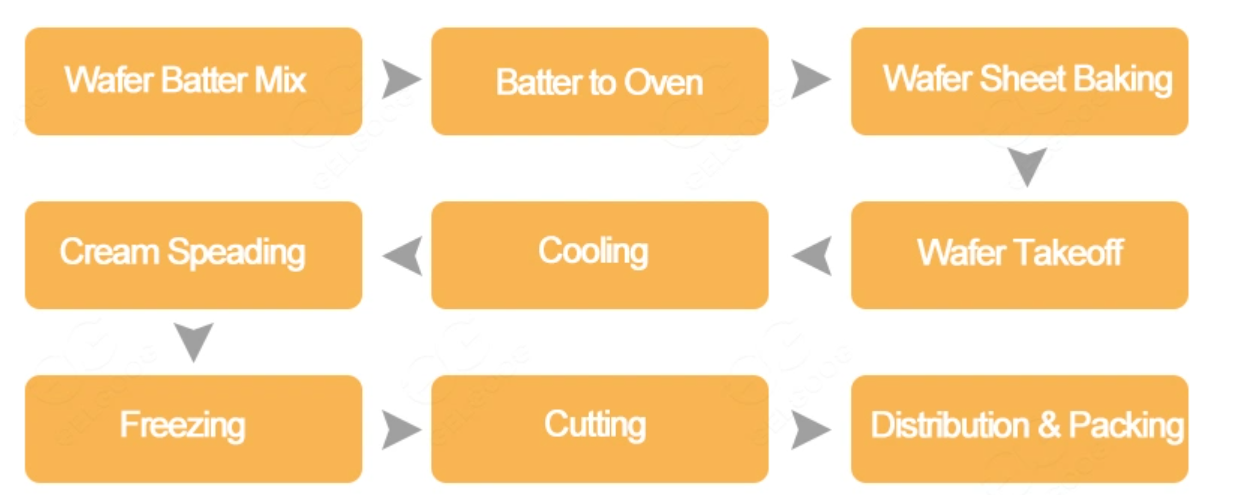

What Are The Steps In Making wafer biscuits ?

What Biscuit Making Machine In Industry are used in Chocolate biscuit?

Wafer Biscuits Making Machine adopts flour, wheat flour, potato starch, potato powder, and corn starch as main materials, to produce a variety of biscuit food in different taste.

It is necessary to use the biscuit production line for production. The technological process is:

Batter Mixing -- Wafer sheet baking -- Wafer Sheet Cooling -- Wafer sheet cream coating -- Wafer sheet cooling -- Wafer biscuits cutting

What is The Application Range?

LY-CF4 automatic feeding,alignment,distribution and packing withou workers and widely used in the food industry,chemical industry,Pharmaceuticals,Hardware and other industry which products are round,square and bar.

How to produce biscuit ?Here is biscuit manufacturing process---

| Wafer Biscuit Making Process | |

| 1 | Dough Mixer |

| 2 | Automatic Dough Tipping and Sending System |

| 3 | Three-roll combination sheeter for feeding and sheeting doug |

| 4 | Laminator for overlapping dough to sheeting on gauge rolls, included flour spreading machine (Special for Soda cracker& Hello Panda biscuit) |

| 5 | Guage Roller |

| 6 | Rotary Cutter with Scrap collection and return system for Hard Biscuit |

| 7 | Rotary Moulder for Soft Biscuit |

| 8 | Tunnel Baking Oven |

| 9 | Cooling Conveyor & Stacker Machine |

| 10 | Packing Table |

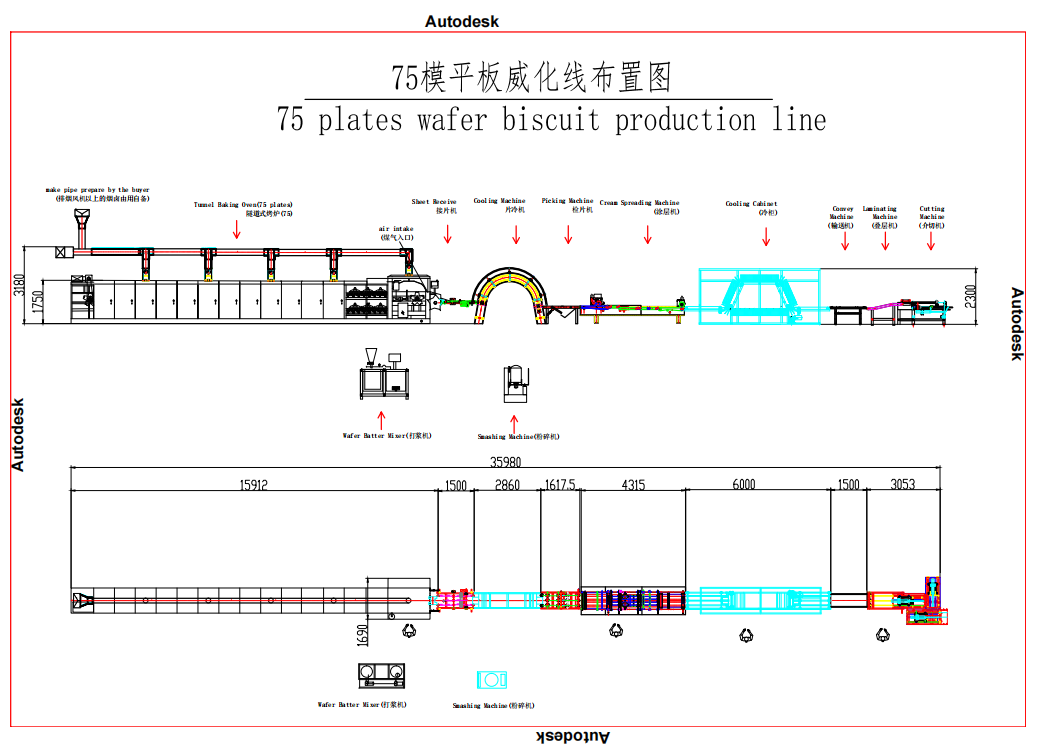

Model Parameters And Price Of Automatic Biscuit Production Line

| Technical Parameters And Price Of Automatic Biscuit Machine | ||||||||

| Models | LY27 | LY33 | LY39 | LY45 | LY51 | LY65 | LY69 | LY75 |

| Baking Oven Length(mm) | 6000 | 7150 | 8300 | 9450 | 10600 | 13300 | 14000 | 16000 |

| Whole Line Length(mm) | 22000 | 23150 | 24300 | 25450 | 26600 | 29300 | 30000 | 35400 |

| Power (Kw) | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 8.12 | 8.12 | 8.12 |

| Consumption LNG(m3/h) | 21 | 26 | 30 | 35 | 40 | 50 | 54 | 58 |

| Capacity(pcs/min) | 14 | 17 | 20 | 23 | 26 | 33 | 35 | 38 |

Siemens Motor Of Wafer Biscuits Making Machine

| Siemens Motor Of Wafer Biscuits Making Machine | ||

| 1 | Package Level 1 Units: | 0 Carton |

| 2 | Product Name: | 3-Phase Squirrel Cage Motor |

| 3 | Product Net Weight: | 5.9 Kg |

| 4 | Product Type: | 3Aa2__M3Aa_Ie2_Aa |

| 5 | Scip: | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (Fi) |

| 6 | Selling Unit Of Measure: | Piece |

| 7 | Standards: | Iec 60034-1 |

| 8 | Starting Of Motor: | Direct Online |

As a small biscuit machine factory,to adopt the small scale biscuit making machine is a good choose ,here was the price of biscuit machine for your refer----

Machine Price For Automatic Biscuit Pellet Machine

| Machine Price For Wafer Biscuits Making Machine | ||

| Output Of Biscuit Making Machine | Price Of Biscuit Making Machine | |

| 1 | 100-150Kg Per Hour | 12,000 Usd-18,500Usd |

| 2 | 150Kg -200 Per Hour | 22,500 Usd-25,500 Usd |

| 3 | 200-300Kg Per Hour | 30,500 Usd-42,500 Usd |

| Batter Mixing -- Wafer sheet baking -- Wafer Sheet Cooling -- Wafer sheet cream coating -- Wafer sheet cooling -- Wafer biscuits cutting | ||

| 2022 model promotion update price need check | ||

Formula Of Biscuit Processing By Wafer Biscuit production line:

| Formula Of Biscuit Processing By Wafer Biscuit production line: | ||

| No. | Ingredient | Content |

| 1 | Flour: | 25kg |

| 2 | Sugar:g | 6k |

| 3 | Palm oil: | 6kg |

| 4 | Butter: | 0.5kg |

| 5 | Water: | 2.5kg |

| 6 | Syrup: | 300g |

| 7 | Ammonium bicarbonate: | 100g |

| 8 | Baking soda: | 100g |

| 9 | Salt: | 150g |

| 10 | Starch: | 1kg |

Main parts of production line for Wafer Biscuits Making Machine

| Main parts of production line for Wafer Biscuits Making Machine | ||

| 1 | Baking oven | This baking oven consists of batter injection system, gas heating system and gas leaking alarm system, plates' transferring and connecting devices, is full metal structure with perfect heat preservation, with elegantappearance. Observation windows are set for each heating area to facilitate the inspection of production, the burner is redesigned and adopts state of art energy-saving burning technology to improve the heat efficiency greatly. The temperature in the oven is uniform. |

| 2 | Cream spreading machine(Single head) | Spreading cream on surface of wafer sheet by pressing roller. The cream hopper with heating device keeping the hopper temperature |

| 3 | Cutting and laminating machine | Laminate the wafer sheet and cutting wafer sheet into wafer bar as per demand |

Whats is Main Features of Automatic Wafer Biscuits Making Machine?

| Main Features of Automatic Wafer Biscuits Making Machine | ||

| 1 | The baking oven has 39 moulds | The mould frame is nodular cast iron, the grilling plate is heat-resistant cast iron, the standard baking pan specification is 470*325 mm, and the maximum is 500*350 mm; the power transmission mechanism and the walking wheel are nationally patented; pid automatic temperature control, wafer film uniform color; |

| 2 | Batter mixer is all stainless steel | Dynamic and static ring blade batter mixer, in 3 minutes, 25 kg of flour can be beaten into batter; electrical design using ip55 waterproof design, batter mixer can be quickly rinsed with water; |

| 3 | Arch type cold film machine is all stainless steel | Independent motor drive; |

| 4 | Cream coating machine | Frame is a stainless steel tank structure, the motor cable and pneumatic components are sealed in the tank slot, waterproof and dustproof; the coating head is a combination structure, and the assembly and disassembly and cleaning are convenient; the stacking mechanism is a rotary plug-in structure. The layer is not controlled by the thickness of the cream layer and the number of lamination layers. The smooth stainless steel laminating roll is particularly easy to clean quickly and does not have a sanitary corner; the pressing mechanism is a double-rolled cake |

| 5 | The freezer is of stainless steel structure | 304 stainless steel parts in contact with the wafer cake, the cooler is external, the inlet temperature of the freezer is 5°c, and the relative humidity of the freezer is 55%; |

| 6 | Fast cutting | The cutting machine is a blade type cutting machine with a standard cutting speed of up to 8 |

Customer Cases For Wafer Biscuit Manufacturing Machine Production Line In 2022

| Dealed Customers Who Purchase Hard Wafer Biscuit Production Line In 2022 | |

| 1 | Sudan 200kg/h Wafer Biscuit Machine |

| 2 | Moldova Small Wafer Biscuit Equipment For Sale |

| 3 | 200kg/h Wafer Biscuit Machine Sold In Ukraine |

| 4 | Nigeria 150Kg/H Wafer Biscuit Prcessing Machine Price |

| 5 | Austria Sells Industrial Wafer Biscuit Production Equipment |

| Customer Case Of Small Scale Automatic Wafer Biscuit Production Line At 2021 | |

| 1 | 100KG/H Thai fully automatic Wafer biscuit production line for Thailand customer |

| 2 | 100KG/H small scale automatic Wafer biscuit making machine for sale in Uzbekistan |

| 3 | 100KG/H fully automatic Wafer biscuit making machine for sale in Nigeria |

| Customer Case Of Industrial Automatic Wafer Biscuit Production Line At 2021 | |

| 1 | Industrial Wafer biscuit making machine fully automatic 100KG/H in Algerian |

| 2 | 80KG/H industrial fully automatic Wafer biscuit making machine for sale in Senegal |

| 3 | 100KG/H industrial Wafer biscuit making machine buy online sold in Russia |

| Customer Have Raw Material Case Of Automatic Wafer Biscuit Production Line At 2021 | |

| 1 | 500KG/H industrial wafer biscuit making machine for sale in Bolivia |

| 2 | Mozambique 500KG/H industrial automatic Wafer biscuit making machine |

| 3 | 300KG/H fully automatic automatic Wafer biscuit production line for sale in Pakistan |