Stainless Steel Continuous Fish Skin Fryer Machine

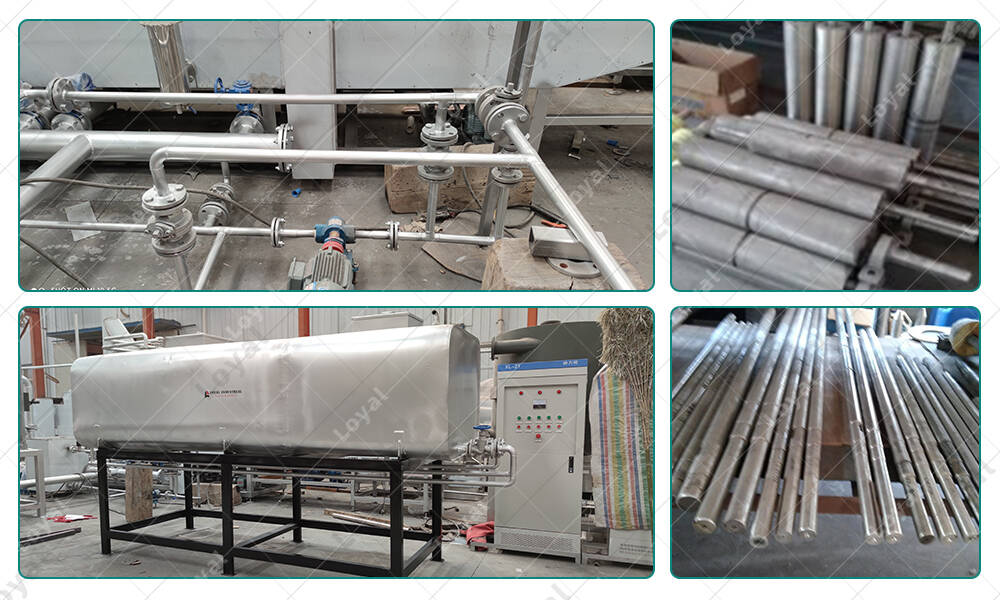

Loyal has been committed to the research and development of food Stainless Steel Continuous Fish Skin Fryer Machine; air fryer fish skin chips fryer is developed by combining advanced technology at home and abroad, after repeated tests. At present, the machinery of loyal stainless steel continuous fish skin fryer machine with deep fryer filter system automatic frying machine has been exported to Singapore, Canada, Brazil, Western Europe and other countries and regions, which has promoted the development of local economy.

The loyal fish skin chip fryer is fully automatic and can process and produce all types of air fryer continuous fry fish skin chips. The fish skin chips continuous fryer has high production efficiency and a wide range of applications, and has become a trusted equipment for air fryer continuous fryer manufacturers.

Stainless Steel Continuous Fish Skin Fryer Machine Specifications :

| Price | Check with frying Machine Team Saler |

| Brand Name | Loyal Stainless Steel Fish Skin Fryer Equipment |

| Place of Origin | China |

| Payment Terms | L/C,D/A,D/P,T/T, |

| Supply Ability | 25Days of Continuous Fish Skin Fryer Machine |

| Team | Professional Fryer Technology Team |

| Process | Ten Years Of Fryer Equipment Manufacturing Process |

Stainless Steel Continuous Fish Skin Fryer Machine Detail Introduction :

Introduction Of Stainless Steel Industrial Crispy Fish Skin Fryer

Stainless steel continuous fish skin fryer machine with deep fryer filter system continuous fryer is water oil frying mixing equipment. The commercial fryer for air fry salmon skin in fried plant sold adopts the most advanced oil mixing principle in the world. The upper layer fry food, the lower layer accepts the sinking residue, the oil will not turn black. This continuous fish skin chip fryer is smokeless and good for the environment. Industrial fryers can be used to fry chicken, chips, doughnuts, snacks and more. Shandong Loyal have designed the high quality industrial crispy fish skin automatic fryer machine solutions based on the needs of our customers to meet different customer needs.The continuous air fry salmon skin fryer sold is completely safe and easy to clean.

How Is Crispy Fish Skin Chips Made With Continuous Fryer Machine?

People also ask how to use automatic frying machine?

Shandong loyal can configure the most suitable stainless steel continuous fish skin fryer machine with deep fryer filter system for different products to optimize the frying effect. The feeding of deep frying machine can be fully automatic, and the discharging is automatic and easy to operate.

Production Process Of Continuous Fish Skin Chips Fryer Machine | ||

1 | Continuous fish skin frying machine | Used for frying many kinds of foods, equipment with timer, temperature controller, automatic stirring device, and automatic unloading device. |

2 | Oil filter | Used for filtering the sediments while frying, try the best to prolong the oil using life. |

3 | De-oiling machine | Centrifugal de-oiling and continuous working, the de-oiling time can be adjusted, frequency conversion control speed, frequency conversion trig. |

4 | Seasoning machine | Continuous flavoring machine, we can adjust the tube speed and powder feeding speed to get the best mixing effect. |

5 | Conveyor | Convey the finished products to the next machine. |

| Flow Chart: Continuous Fish Skin Deep Frying Machine -- Oil Filter -- De-Oiling Machine -- Seasoning Machine -- Conveyor | ||

What Is The Technical Parameter Of Crispy Fish Skin Automatic Fryer Machine?

Technical Parameter Of Automatic Fish Skin Chips Fryer Machine | ||||

Model of fryer | Dimension(mm) | Capacity(kg) | Power(kw) | Weight(kg) |

LY-BM 1000 | 2000*1200*1600mm | 100-150kg/h | 36kw | 300kg |

LY-BM 2000 | 2500*1300*1650mm | 150-200kg/h | 48kw | 400kg |

LY-BM 3000 | 3500*1600*1700mm | 200-300kg/h | 60kw | 580kg |

LY-BM 5000 | 4500*1900*1800mm | 300-500kg/h | 82kw | 720kg |

What Brand Of Motors Can We Supply?

ABB Motor Of Fish Skin Chips Frying Machine | ||

1 | Package level 1 units | 0 carton |

2 | Product name | 3-Phase squirrel cage motor |

3 | Product net weight of industrial fish skin chips fryer | 5.9 kg |

4 | Product type | 3AA2__M3AA_IE2_AA |

5 | Scip of air fry salmon skin deep fryer machine | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

6 | Selling unit of measure | piece |

7 | Standards of continuous fish skin fryer machine | IEC 60034-1 |

8 | Starting of motor | Direct Online |

What Is The Features Of Industrial Fish Skin Chips Fryer?

The Stainless steel continuous fish skin fryer machine with deep fryer filter system produced by Shandong Loyal company has a variety of frying forms and models to meet the needs of different customers. Commercial fryer machine is mostly used for frying shrimp chips, potato chips, fish, peanuts and other foods.

Features of High Quality Automatic Continuous Fish Skin Fryer Machine | |

1 | Heating source of continuous fish skin fryer machine: electricity or gas. |

2 | Automatic mixing: to ensure products being uniformly fried and prevent them from compression and adhesion. |

3 | Automatic discharging and optional automatic feeding: through motor-driven manner to reduce labor intensity. |

4 | Automatic temperature control of circular deep fryer: 0-300°C to be set at your will. |

5 | Oil-water separation filtering system or pure oil filtering system. |

6 | Air fry salmon skin deep fryer machine can be widely used to fry the snacks, pellets, potato chips, sticks, beans, nuts, peanuts etc. |

7 | The whole deep fat fryer machine is made of stainless steel 304. |

What is Application Range Of Commercial Deep Fryer Fish Skin Chips?

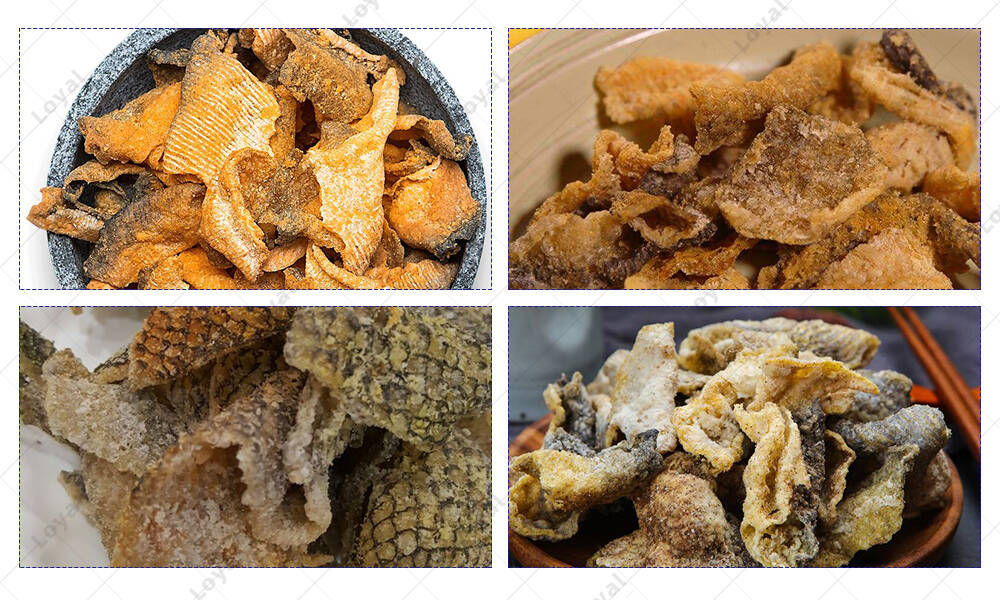

Stainless steel continuous fish skin fryer machine with deep fryer filter system is widely used in crispy fish skin shrimp chips, fried dried fruit nuts, puffed food, meat product,etc, such as rice crisp, sweet sticky rice strips, peanut, beans, and fried cake with sugar, squid, fried chicken, and so on, an ideal frying equipment to produce fried food.

The Application Of Continuous Fish Skin Chips Frying Machine | ||

1 | Cooked wheaten food | Fried dough twist, rice crust, honey food, honey mito, deep-fried dough sticks, fried glutinous rice balls with sesame, gluten, polished glutinous rice stick, caramel treats, thin fried dough twist, etc. |

2 | Meat | Braised chicken (coloring), pressed salted duck (coloring), braised pork, ball, sliced dried beef, streaky pork, drumstick, pig's feet, etc. |

3 | Marine food products | Various fish, crispy fish skin,peeled prawns, scallop, mytilidae, aberdeen fish, squid rings, squid. |

4 | Bean products | Dried tofu, bean curd, fish bean curd, bread made by tofu. |

5 | Nut fruits | Groundnut kernels, green soya bean, broad bean, sunflower seed. |

6 | Miscellaneous | Vegetable pie, tempura, eggplant box, lotus root box, various fried puffed food with syrup and paste. |

Which Market Did The Loyal Continuous Salmon Skin Crisps Deep Fryer Machine?

Customer Case Of Continuous Fish Skin Chips Frying Machine At 2021 | |

1 | 500kg/h Thai stainless steel continuous fish skin fryer machine with deep fryer filter system for Thailand customer |

2 | 300kg/h large scale high quality commercial frying machine for air fry salmon skin for sale in Uzbekistan |

3 | 500kg/h automatic air fry salmon skin frying machine for sale in Nigeria |

4 | 600kg/h best price industrial salmon skin crisps fryer continuous deep frying machine for factory in Canada |

5 | 1000kg/h industrial crispy salmon skin deep fryer machine equipment for sale in Japan |

6 | English 200kg/h high quality commercial frying machine for salmon skin crisps |

7 | Bangladesh 200kg/h fully automatic air fry salmon skin deep fryer machine |

Customer Case Of Commercial Frying Machine For Fish Skin Chips At 2021 | |

1 | Stainless steel continuous fish skin fryer machine with deep fryer filter system 500kg/h in Algerian |

2 | 800kg/h industrial crispy salmon skin deep fryer machine for sale in Senegal |

3 | 600kg/h stainless steel continuous fish skin fryer machine with deep fryer filter system sold in Russia |

4 | 400kg/h cost of high quality commercial frying machine for salmon skin crisps sold in Japan |

5 | 200kg/h industrial commercial fried salmon skin chips frying machine plant for factory for sale in Egypt |

6 | 1000kg/h industrial fried salmon skin chips frying machine price for sale in Bolivia |

7 | Senegal 100kg/h industrial fully automatic commercial crispy salmon skin frying machine plant |

Customer Case Of Industrial Salmon Skin Crisps Deep Fryer Machine At 2021 | |

1 | 500kg/h industrial crispy salmon skin deep fryer machine for sale in Bolivia |

2 | Mozambique 500kg/h best price industrial fish skin chips fryer continuous deep frying machine |

3 | 300kg/h industrial continuous fish skin chips commercial deep fryer filter system for sale in Brazil |

4 | 150kg/h Thai commercial fish skin chips frying machine plant for factory |

5 | Egypt 100kg/h fully automatic crispy salmon skin deep fryer machine price |

6 | USA 1000kg/h high quality industrial crispy fish skin automatic fryer machine |

7 | 800kg/h industrial salmon skin crisps frying machine for sale in Japan |