Chocolate Wafer Making Machine

As a professional chocolate wafer making machine manufacturer, we can supply small, medium and large automatic wafer biscuit production lines. Wafer biscuit production line is reasonable in price, reliable in performance, compact in structure, small in floor space, high in output, low in energy consumption, convenient in maintenance and simple in operation. The automatic chocolate wafer

Chocolate Wafer Making Machine Specifications :

| Brand Name | LOYAL |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T |

| Delivery Detail | 30days /Chocolate Wafer Making Machine |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

Chocolate Wafer Making Machine Detail Introduction :

As a professional chocolate wafer making machine manufacturer, we can supply small, medium and large automatic wafer biscuit production lines. Wafer biscuit production line is reasonable in price, reliable in performance, compact in structure, small in floor space, high in output, low in energy consumption, convenient in maintenance and simple in operation. The automatic chocolate wafer making machine has an operating system programmed with PLC which makes the process automated and easy to control. We can design molds for wafer biscuit production line according to customer requirements.

What is Chocolate Wafer Making Machine

The technology of chocolate wafer making machine is advanced, we can introduce how wafer biscuit is made. The wafer biscuit production line is a new generation of products designed and developed in combination with the advanced structure of similar products at home and abroad.This chocolate wafer making machine production line consists of material mixing system, automatic feeding machine, gas tunnel oven, sheet delivery machine, cooling machine, coating machine, slicing machine, etc., with compact structure, good stability, the preferred equipment for food industry.

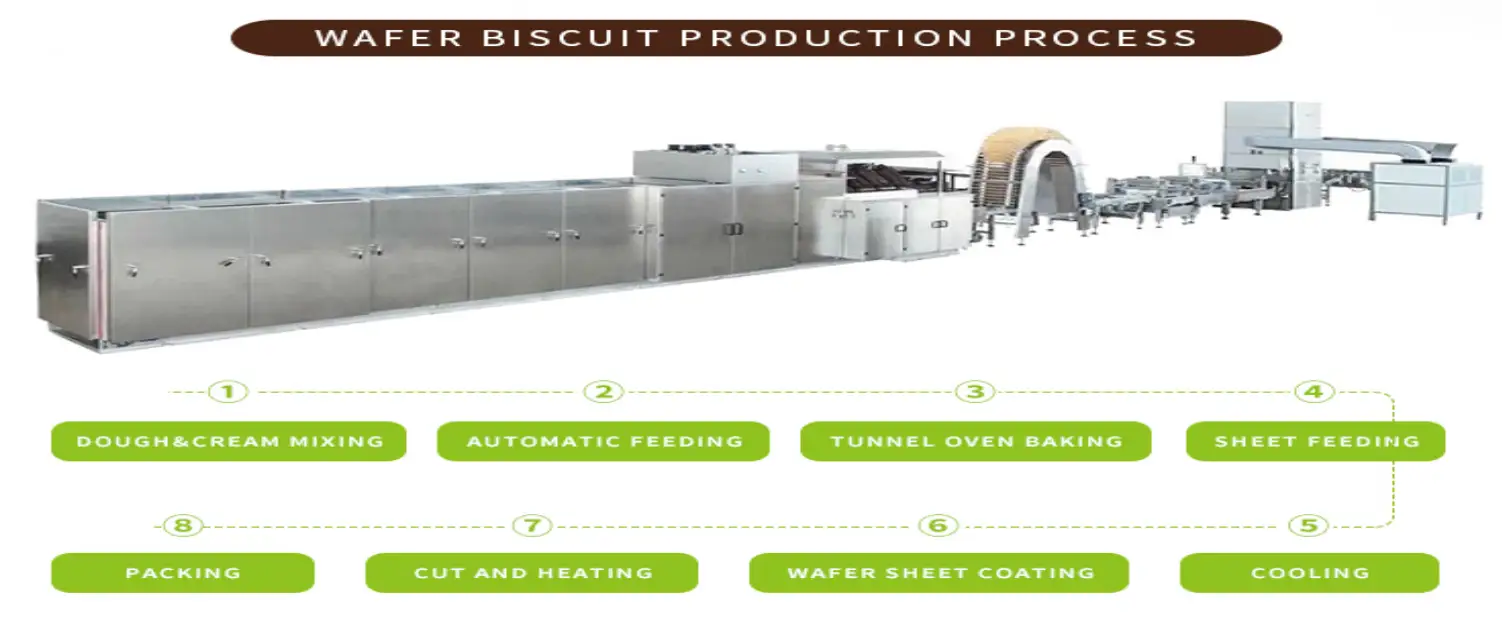

Production Process Of The Automatic Chocolate Wafer Making Machine

| Main Equipment List Of Automatic Chocolate Wafer Making Machine | |

| 1 | Batter Mixer for the Wafer Biscuit Dough |

| 2 | Wafer Baking Oven,Different model of chocolate wafer making machine according to different capacity |

| 3 | Sheet Received Machine For Wafer sheets from Oven |

| 4 | Horizontal or Vertical Door Cooling Tower |

| 5 | Sheet Picking Machine For Wafer Sheets from Cooling Tower |

| 6 | Cream spreading machine with roller heating system, One Color(cream or chocolate available) |

| 7 | Cooling Cabinet&Cooling Compressor |

| 8 | Sheets Laminated Machine , Sheets Laminated Machine |

| 9 | Cutting Machine of chocolate wafer making machine, Knife cut type |

| 10 | Cream Mixer For Cream or Chocolate |

| 11 | Smash Machine For Recycle |

| 12 | Chocolate Coating Machine with Cooling Tunnel |

| 13 | Wafer Packing System |

Technical Parameters of Chocolate Wafer Making Machine

| Technical Parameters of Wafer Biscuit Processing Line | |||||||

| Baking Oven Length(mm) | 6000 | 6750 | 7150 | 8300 | 9450 | 10600 | 13300 |

| Whole Line Length(mm) | 22000 | 22750 | 23150 | 24300 | 25450 | 26600 | 29300 |

| Power(kw) | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 | 5.52 |

| LPG(kg/h) | 13 | 15 | 15 | 19 | 23 | 27 | 32 |

| LNG(m3/h) | 16 | 19 | 21 | 25 | 30 | 35 | 45 |

| Electrical Heating Power(kw) | 90 | 105 | 110 | 130 | 150 | 270 | 215 |

| Capacity of Chocolate Wafer Making Machine(pcs/min) | 14 | 16 | 17 | 20 | 23 | 26 | 33 |

What is Features Of Automatic Commercial Chocolate Wafer Processing Line

| Main Equipment Features Of Automatic Chocolate Wafer Making Machine | ||

| 1 | Batter Mixer for the Wafer Biscuit Dough | This model of chocolate wafer making machine is an integrated mixer, which is specially used in the wafer production system.The capacity of the mixer can be converted from 25 kg of flour to 65 kg of batter after 5 minutes of mixing. |

| 2 | Wafer Baking Oven | This wafer baking oven is very important in the chocolate wafer making machine. The waffle baking system uses LPG to heat the baking board, which is controlled by a German Siemens PLC. The function of the oven is to automatically fill the baking board with batter until the baked waffle comes out of the oven. |

| 3 | Splicing Machine | Wafer splicing machine will bake good wafer into cooling channel, transmission and gently wipe out bread slice of the powder on the head, to roast hot wafer piece will not damage. |

| 4 | Vertical Cold Sheet Machine | This chocolate wafer making machine can improve the natural cooling effect of wafer and gently transport wafer. The main function of this cold machine is to ease the thermal stress of wafer when baking. |

| 5 | Picking Machine | The function of the machine is used in the collection of cake pieces; If there is a temporary failure in either one of the coating machine and cooling chamber of the chocolate wafer making machine, the machine will automatically collect the qualified wafer continuously. |

| 6 | Cream Coating Machine | This machine is an important machine to determine the quantity distribution of wafer and cream layer of chocolate wafer making machine. It has the following functions: Apply cream layer on the cooled wafer, evenly spread cream and apply each layer of cream on each layer of cake, and then slightly pressure to combine cake and cream. |

| 7 | Vertical Refrigerator (Air Cooled) | Cooling the waffle makes the waffle firm enough for easy cutting and packaging. Cooling the waffle ensures a clean cut. |

| 8 | Cutting Machine | The mechanical cutting machine of chocolate wafer making machine is mainly used for cutting the wafer cake block, the lamination number can be controlled according to the requirements, the cutting size can be prefabricated tool carrier replacement, the machine cutting is mechanical control (non-pneumatic). |

Commercial Chocolate Wafer Samples

This chocolate wafer making machine is mainly used to produce wafer biscuits, such as Sandwich wafer, Coating wafer , Wafer volume and so on.

Packing And Delivery Of Wafer Biscuit Processing Line

| Packing And Delivery Of Automatic Chocolate Wafer Making Machine | |

| 1 | Mechanical surface coated with preservative solution (to protect stainless steel). |

| 2 | The plastic cushion packing machine (prevent bump). |

| 3 | The chocolate wafer making machine use plastic film packaging (to prevent ventilation). |

| 4 | Wooden case / frame packaging (easy to transport). |

| 5 | Tie the bandage outside of the wooden case (reinforcement overall). |

Which Market Did The Loyal Wafer Biscuit Making Equipment Sold?

The fully automatic wafer biscuit making machine is novel in design and compact in structure. Full automatic industrial wafer machine for sale from raw materials to finished products is fully automatic and has a high degree of automation.At present, the machinery of loyal chocolate wafer making machine has been exported to Singapore,Nigeria,India, Canada, Brazil, Russia, Belgium, Liberia,Morocco, South Africa, South Korea, Bangladesh, United Kingdom,Western Europe and other countries and regions, which has promoted the development of local economy.

| Customer Case Of Small Scale Automatic Chocolate Wafer Making Machine At 2021 | |

| 1 | 100KG/H Thai fully automatic chocolate wafer making machine for United Kingdom customer |

| 2 | 100KG/H small scale automatic wafer making machine for sale in South Korea |

| 3 | 100KG/H fully automatic chocolate wafer making machine for sale in Nigeria |

| Customer Case Of Industrial Automatic Biscuit Production Line At 2021 | |

| 1 | Industrial wafer biscuit making machine fully automatic 1000KG/H in Algerian |

| 2 | 800KG/H industrial wafer fully automatic biscuit making machine for sale in Bangladesh |

| 3 | 1000KG/H industrial chocolate wafer making machine buy online sold in Russia |

| Customer Have Raw Material Case Of Automatic Chocolate Wafer Processing Line At 2021 | |

| 1 | 500KG/H industrial wafer chocolate biscuit making machine for sale in Bolivia |

| 2 | Mozambique 600KG/H industrial chocolate wafer making machine |

| 3 | 1000KG/H fully automatic automatic wafer chocolate biscuit production line for sale in Brazil |