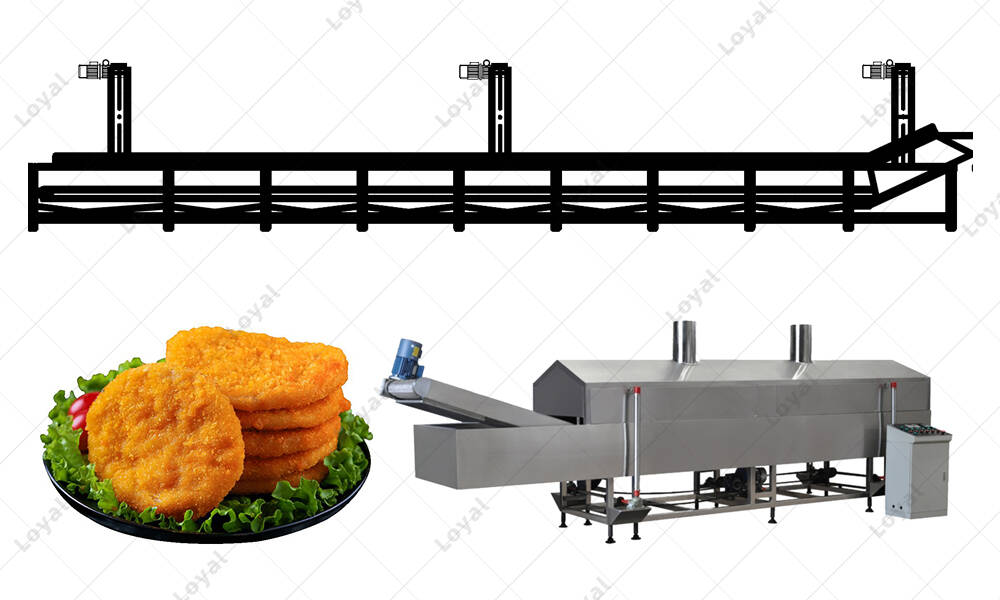

Fully Automatic Hamburger Patty Frying making machine

Fully Automatic Hamburger Patty Frying making machine

As a professional Fully Automatic Hamburger Patty Frying making machine manufacturer, our loyal deep fat fryer filter system hamburger patty frying machine fryer oil filtration system is fully automatic and can process and fry various types of products, commercial deep fryer with oil filtration system for burger patties has high production efficiency and a wide range of applications, and has become a trusted fryer oil filtration equipment for hamburger patty food manufacturers.

Fully Automatic Hamburger Patty Frying making machine Specifications :

| Price | Check with fryer Machine Team Saler |

| Brand Name | LOYAL Hamburger Patty Frying equipment |

| Model Number | Tunnel Microwave Dryer Condiment Sterilization Equipment |

| Min.Order Quantity | 1set |

| Supply Ability | 25Days of Automatic Hamburger Patty Frying making machine |

| Sale Team | Fryer Machine Technical Team |

| Honor | A Number Of National Fryer Equipment Patents |

Fully Automatic Hamburger Patty Frying making machine Detail Introduction :

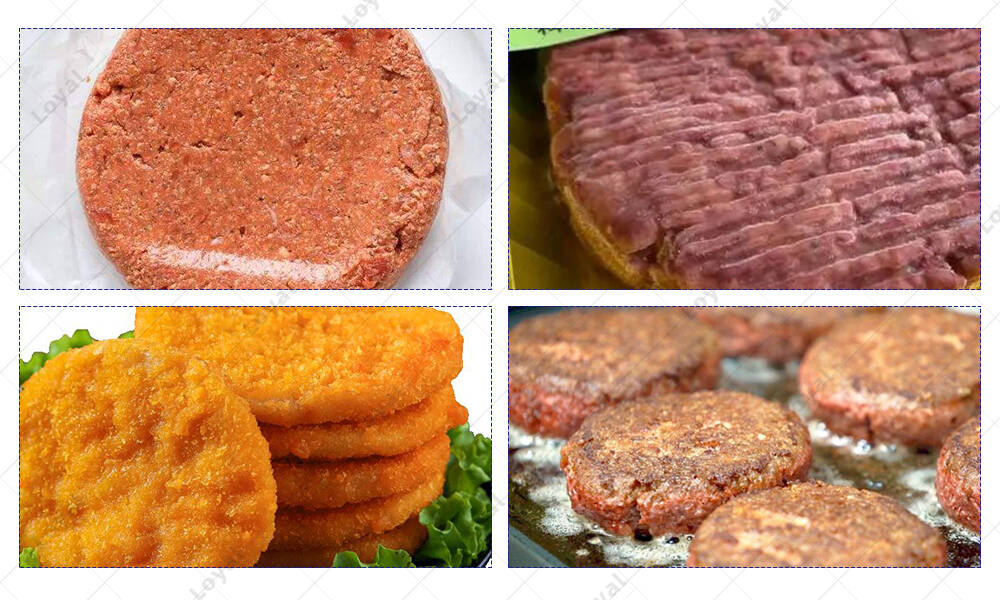

Can Beef Patties Be Fried?

This beef patty frying machine deep fryer oil filter system has been specially developed for a variety of foods. The stock rotates automatically during frying. This machine adopts high temperature heat conduction oil as the heat source, which avoids the damage to the oil by direct heating. At the same time, the energy can be coal, gas, diesel and other fuels, and the application range is very wide. The deep fat fryer filter system hamburger patty frying machine fryer oil filtration system has low oil output and high oil output speed, and the oil is filtered during the cycle to keep it clean. It is a special fryer for beef patty and hamburger patty.

What’s The Parameters And Price Of The Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System?

Parameters And The Price Of Hamburger Patty Frying Machine Frying System | |||||||

Model | Machine Size (Mm) | Inner Size (Mm) | Power (Kw) | Voltage (V) | Temperature (°C) | Oil Capacity(L) | Price (USD) |

LY-1000 | 1400*1200*1300 | 1000*1000 | 30 | 380 | 0-300 | 400 | 12,000-18,000 |

LY-1200 | 1600*1400*1300 | 1200*1200 | 60 | 380 | 0-300 | 600 | 19,000-27,000 |

LY-1500 | 1900*1700*1300 | 1500*1500 | 72 | 380 | 0-300 | 800 | 29,000-37,000 |

Why Choose Loyal Burger Patties Frying Machine With Oil Filtration Systems For Deep Fryers?

More Details Of The Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System | |

| 1 | The Main Body Of The Industrial Deep Fryer Beef Patty Frying Making Is Made Of SUS304 Stainless Steel. |

| 2 | The Patty Fryer With Oil Filtration System Adopts The Mixing Method Of Revolution And Rotation Synchronously To Ensure The Uniformity Of Food Frying, Prevent Food From Sticking To Each Other Due To Extrusion, And The Mixing System Uses Frequency Conversion Speed Regulation. |

| 3 | The Automatic Discharging System Reduces The Labor Intensity Of The Workers, Ensures The Consistency Of The Cooking Time Of The Food In The Frying Machine, And Improves The Product Quality. |

| 4 | The Automatic Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System Series Is Suitable For Fast Food Restaurants, Canteens, Chain Stores, Small And Medium-Sized Fried Food Processing Enterprises, And Is Widely Used In The Frying Of Meat, Aquatic Products, Vegetables, Pasta, Soy Products, Etc., With Electricity As Heating Energy. |

| 5 | The Fried Food Is Not Only Good In Color, Fragrance And Taste, But Also Has a Clean And Beautiful Appearance. The Commercial Deep Fryer With Oil Filtration System For Burger Patties Frying Machine Also Improves The Quality Of The Product And Extends The Shelf Life. The Device Can Be Used For Multi-Purpose Frying. |

Which Market Did The Loyal Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System Sold To?

Customers Have Patty Formula Request Of Patty Fryer With Oil Filtration System | |

| 1 | Spain 300T/Year Industrial Patty Frying Machine Production Line |

| 2 | 1T/H Patty Oil Filtration Systems For Deep Fryers For Sale In Puerto Rico |

| 3 | 1T/H Patty Fryer With Oil Filtration System For Sale In Bolivia |

| 4 | Senegal 1T/H Industrial Patty Frying Machine Equipment |

| 5 | India 1T/H Commercial Deep Fryer With Oil Filtration System For Burger Patties Frying Machine |

| 6 | 1T/H Industrial Burger Frying Machine Deep Frying Machine Sold In Russia |

Cooperated Customer Request Engineer Installation Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System At 2021 | |

| 7 | 100kg/H Industrial Patty Making Machine For Sale In Uzbekistan |

| 8 | 100kg/h Chicken Patties Frying Machine Fryer With Oil Filtration System For Sale In Senegal |

| 9 | Mozambique 1T/H Automatic Deep Fryer For Patty Making Machine |

| 10 | Bangladesh 2t/h Commercial Deep Fryer With Oil Filtration System For Burger Patties Frying Machine |

| 11 | 1T/H 3D Industrial Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System |

| 12 | Uzbekistan 1T/H Industrial Fryer For Patty Machine Manufacturing Equipment |

| 13 | USA 1T/H Industrial Chicken Patties Frying Machine Fryer With Oil Filtration System |

| 14 | 500kg/h Industrial Deep Fryer Beef Patty Frying Making For India |

Second- Cooperation Customers Of Commercial Deep Fryer With Oil Filtration System For Burger Patties Frying Machine At 2021 | |

| 15 | Algerian Patty Frying Machine 300kg/h Production Line |

| 16 | Sudan 200kg/h Industrial Deep Fryer Beef Patty Frying Making Industrial Deep Fryer |

| 17 | Moldova Small 200kg/h Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System |

| 18 | 200kg/h Beef Burger Frying Machine Sold In Ukraine |

| 19 | Nigeria 150Kg/H Commercial Deep Fryer With Oil Filtration System For Burger Patties Frying Machine |

| 20 | Austria Sells Industrial Deep Fryers For Patty Machine 100kg/h |

Cooperated Agent Of Deep Fat Fryer Filter System Hamburger Patty Frying Machine Fryer Oil Filtration System For Patty At 2021 | |

| 21 | Nigeria 150Kg/H 3D Industrial Deep Fryer Beef Patty Frying Making Machinery |

| 22 | Vegetable Industrial Deep Fryer For Patty Machine For Sale In Pakistan 100kg/h |

| 23 | Austria Sells Commercial Deep Fryer With Oil Filtration System For Burger Patties Frying Machine 100kg/h |

| 24 | 500Kg/H Fryers Patty Fryer Oil Filtration System For Sale |

| 25 | Sudan 250kg/h Small Industrial Deep Fryer Beef Patty Frying Making |

| 26 | Algerian Patty 300kg/h Burger Frying Machine Deep Frying Machine |