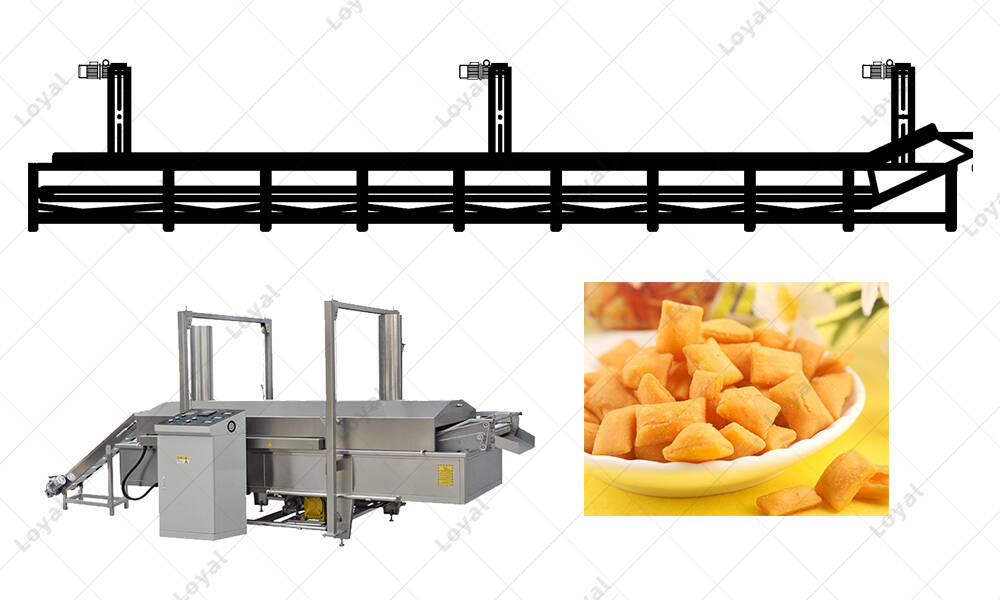

Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine

Loyal can offer frying machine for Chin Chin plant to make chin chin, which with high quality chin chin processing technology, much stable and easy operation, with very competitive frying machine for Chin Chin price. Loyal has a number of chin chin frying machine project technology patents, and industrial continuous frying machine commercial automatic chin chin fryer machine can save chin chin frying machine costs while improving good development in the chin chin frying machine manufacturing industry.

Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine Specifications :

| Brand Name | LOYAL Automatic Fryer Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Chin Chin Continuous Fryer making machine |

| Payment Terms | D/P,T/T, |

| Delivery Detail | 20days--35days |

| Packaging Details | Export-compliant fryer equipment packaging |

| Honor | A Number Of National Fryer Equipment Patents |

| Technology | Ten Years Of Fryer Equipment Manufacturing Process |

Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine Detail Introduction :

How Do I Start The Successful Chin Chin Business?

Industrial continuous frying machine commercial automatic chin chin fryer machine consists of: belt conveying system, automatic rising system, automatic filter system, automatic oil temperature controlling system, oil adding system and heating system. Automatic chin chin frying machine can be used in fried dried fruit nuts, puffed food, meat product, etc, such as potato chips, rice crisp, sweet sticky rice strips, peanut, beans, and fried cake with sugar, squid, fried chicken, and so on. We can customize commercial fully automatic chin chin fryer plant according to your product and special requirements, and we also provide semi-automatic batch frying machine for choose.

Technicial Parameter Of Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine?

Technical Parameter Of Continuous Chin Chin Fryer | ||||

Model | Dimension(mm) | Weight(kg) | Capacity(kg/h) | Power(kw) |

LY3500 | 3500*1200*2400 | 1000 | 500kg | 80 |

LY4000 | 4000*1200*2400 | 1200 | 600kg | 100 |

LY5000 | 5000*1200*2400 | 1500 | 800kg | 120 |

LY6000 | 6000*1200*2400 | 1800 | 1000kg | 180 |

Detailed Parameter of Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine

Parameter Of Automatic Chin Chin Continuous Frying Machine | ||

1 | Frying Product | Snacks, Nuggets Burger, Fish, Peanuts And So On |

2 | Heating Method | Electricity/ Gas/Lpg/ Diesel/ Wood |

3 | Model | Xdl-2500/3500/4500/5500/6500/8500/11000 |

4 | Rated Power | Different Based On Model And Products |

5 | Frying Temperature | 155-180℃ |

6 | Frying Temperature Range | 80-300℃ |

7 | Temperature Precision | ±1℃ |

8 | Frying Time | 1-5mintues Adjustable |

9 | Frying Time Control Range | Frequency Adjustable |

10 | Mesh Belt Width | 300mm/400mm/600mm/800mm/1000mm/1200mm |

Specifications Of Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine

Parameter Of Automatic Chin Chin Continuous Frying Machine | ||

1 | Frying Product | Snacks, Nuggets Burger, Fish, Peanuts And So On |

2 | Heating Method | Electricity/ Gas/Lpg/ Diesel/ Wood |

3 | Model | Xdl-2500/3500/4500/5500/6500/8500/11000 |

4 | Rated Power | Different Based On Model And Products |

5 | Frying Temperature | 155-180℃ |

6 | Frying Temperature Range | 80-300℃ |

7 | Temperature Precision | ±1℃ |

8 | Frying Time | 1-5mintues Adjustable |

9 | Frying Time Control Range | Frequency Adjustable |

10 | Mesh Belt Width | 300mm/400mm/600mm/800mm/1000mm/1200mm |

Features Of Commercial Electric Continuous Fryer For Chin Chin

Features Of Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine | |

1 | Heating source of chin chin frying machine: electricity or gas or diesel. Gas heated batch frying uses Italy imported brand burner which is the most advanced and reliable burner: fuel economy, low noise, prevent heating loss, high efficiency |

2 | Chin chin frying machine for finger chips body is made of stainless steel. |

3 | Dual mesh belts deliver food, and the belt speed can be frequency-converted. |

4 | Chin chin frying machine automatic lifting system is convenient for workers to clean the body. |

5 | Advanced temperature control device and reasonable stirring device ensure the best frying quality. |

6 | Industrial continous frying machine commercial automatic chin chin fryer machine has constant temperature continuous production ensures the consistency of the temperature and time of the fried food. |

7 | Automatic frying machine for chin chin adopts the process of oil and water mixing, the residue in food can automatically sink into the water to keep the oil clean. |

Application Of Continuous Fryer For Chin Chin

Application Of Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine | |

1 | Chicken Wings Frying |

2 | Nuggets Burger Frying |

3 | Potato Chip,French Fries Frying |

4 | Snack Food Frying |

5 | Peanuts Frying |

6 | Fish Frying |

2021 Customer Order Chin Chin Continuous Frying Machine For Frying Chin Chin Form

Customers Who Understand The Continuous Frying Machine For Frying Chin Chin Processing Technology | |

1 | 500kg/h Continuous Frying Machine For Frying Chin Chin For Sale In Afghanistan |

2 | India 600kg/h Fully Automatic Frying Machine Industrial Frying Machine For Chin Chin For Sale In Argentina |

3 | High Quality Most Popular Industrial Continuous 500kg/h Frying Machine For Frying Chin Chin For Sale In Comoros Factory |

4 | 800kg/h Chin Chin Mini Industrial Frying Machine For Chin Chin For Sale In Afghanistan |

5 | 600kg/h Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine For Sale In Argentina |

Customers Who Purchase Big Output Frying Machine For Chin Chin In 2021 | |

1 | 600kg/h Industrial Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine Customized For Sale In Congo |

2 | 300kg/h Frying Machine For Chin Chin For Sale Chin Chin Industrial Frying Machine In Denmark |

3 | 600kg/h Tunnel Industrial Frying Machine Plant For Chin Chin For Sale In Congo |

4 | Customized High Efficiency 800kg/h Frying Machine For Chin Chin Chin Chin Industrial Frying Machine For Sale In India |

5 | Continuous Frying Machine For Chin Chin Chin Chin 200kg/h Industrial Frying Machine For Sale In Denmark |

Customer Have Plant Of Frying Machine For Chin Chin In 2021 | |

1 | 600kg/h Industrial Continuous Frying Machine Tunnel Industrial Frying Machine For Chin Chin For Sale In Fiji |

2 | 500kg/h High Efficiency 300kg/h Tunnel Frying Machine For Chin Chin For Sale In Fiji |

3 | 1000kg/h Continuous Frying Machine Commercial Automatic Chin Chin Fryer Machine For Sale In Germany |

4 | 800kg/h Continuous Frying Belt Tunnel Tunnel Frying Machine For Chin Chin For Sale In Germany |

5 | 700kg/h Industrial Frying Machine For Chin Chin Continuous Frying Machine For Frying Chin Chin For Sale In India |

Customer Whose Instruction Of Old Customer Of Frying Machine For Chin Chin In 2021 | |

1 | 300kg/h Stainless Steel Frying Machine For Chin Chin Belt Tunnel Tunnel Frying Machine For Sale In Laos |

2 | 1000kg/h Stainless Steel Frying Machine For Chin Chin For Sale In Lebanon |

3 | 700kg/h Continuous Frying Machine For Frying Chin Chin Belt Tunnel Tunnel Frying Machine For Sale In Lesotho |

4 | 500kg/h Automatic Stainless Steel Frying Machine For Chin Chin For Sale In Mali |

5 | 600kg/h Fully Automatic Stainless Steel Frying Machine For Chin Chin For Sale In Nauru |