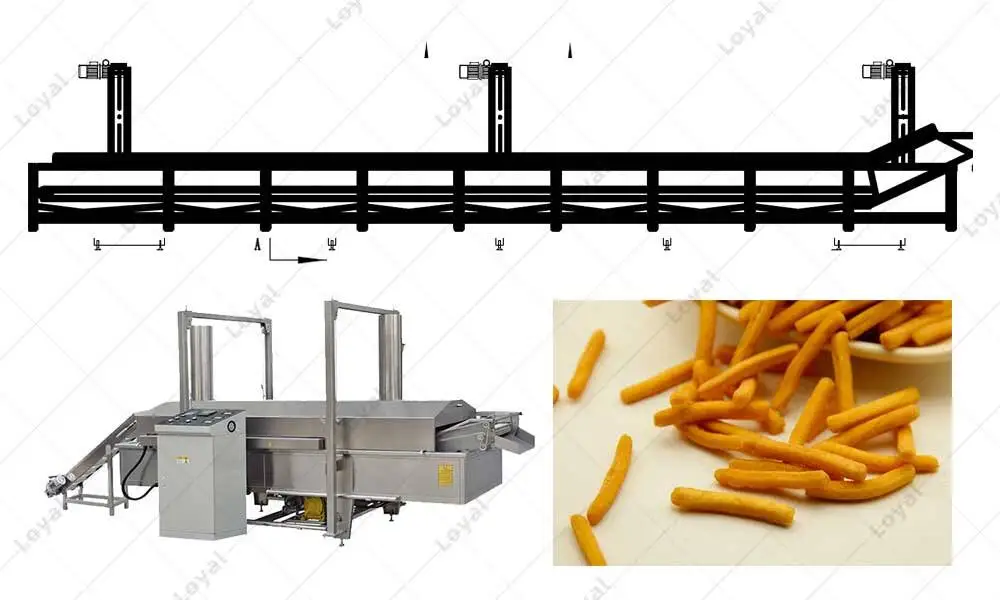

Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment

The fully automatic series of Namkeen snack deep frying equipment is mainly suitable for larger Namkeen snack food production enterprises. Continuous frying machine automatic fryer namkeen snack deep frying equipment can be customized and designed according to product characteristics and better stability. And the animal oil leached from the fried food Namkeen snack deep frying naturally sinks into the lower layer of vegetable oil, so that the working oil in the middle and upper layers is always maintained. Continuous frying machine automatic fryer namkeen snack deep frying equipment can fry all kinds of food at the same time, without smelling each other, one machine is multi-purpose, which can increase your business variety.

Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment Specifications :

| Price | Check with Frying Machine Team Saler |

| Model Number | Automatic Snack Deep Frying processing line |

| Place of Origin | China |

| Payment Terms | L/C,D/A,D/P,T/T, |

| Supply Ability | 25Days of Continuous Frying Machine Equipment |

| Team | Fryer Machine Technical Team |

| Sales Team | Professional Fryer Technology Team |

| Honor | A Number Of National Fryer Equipment Patents |

| Technology | 8 Years Of Fryer Technology |

Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment Detail Introduction :

Introduction Of Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment

Continuous frying machine automatic fryer namkeen snack deep frying equipment's supporting automatic circulation filtration, automatic oil replenishment and other systems can effectively improve the degree of automation and reduce operating costs; electricity, heat transfer oil, coal, natural gas, liquefied gas and external circulation heating can be used for energy.

The process of Namkeen snack deep frying equipment is controlled by limit position, temperature control by zone, scientifically using the specific gravity relationship between vegetable oil and animal oil, so that the animal oil leached from the fried food Namkeen snack deep frying naturally sinks into the lower layer of vegetable oil, so that the working oil in the middle and upper layers is always maintained. Continuous frying machine automatic fryer namkeen snack deep frying equipment can fry all kinds of food at the same time, without smelling each other, one machine is multi-purpose, which can increase your business variety.

Parameters Of Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment

Industry Large Fried Snack Fried French Fries Continuous Frying Machine | ||

1 | Frying product | Snacks, nuggets burger, fish, peanuts and so on |

2 | Heating method | Electricity/ gas/lpg/ diesel/ wood |

3 | Model | LY-2500/3500/4500/5500/6500/8500/11000 |

4 | Rated power | Different based on model and products |

5 | Frying temperature | 155-180℃ |

6 | Frying temperature range | 80-300℃ |

7 | Temperature precision | ±1℃ |

8 | Frying time | 1-5mintues adjustable |

9 | Frying time control range | Frequency adjustable |

10 | Mesh belt width | 300mm/400mm/600mm/800mm/1000mm/1200mm |

11 | Price | 4500usd--10000usd |

| Namkeen fryer prices are promotional prices for 2022, updated prices can be consulted with our Namkeen fryer team. | ||

Features Of Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment

Features Of Continuous Namkeen Snack Fryer Machine | |

1 | Continuous Namkeen fryer machine's mesh belt transmission adopts variable frequency stepless speed regulation. Controllable frying time. |

2 | The continuous Namkeen fryer machine has an automatic lifting system, and the upper cover and mesh belt can be raised and lowered for easy cleaning. |

3 | The bottom of continuous Namkeen fryer machine is equipped with a slag discharge system, which can discharge the generated residue at any time. |

4 | Continuous Namkeen fryer machine adopts high-efficiency thermal conductivity device, which has high energy utilization rate, which is beneficial to reduce the cost of enterprises. |

5 | Continuous Namkeen fryer machine uses electricity, coal or natural gas as heating energy, and the whole machine is made of food grade 304 stainless steel. |

6 | The continuous Namkeen fryer machine uses upper and lower double-layer mesh belts for transmission, and the product is sandwiched between the double-layer mesh belts to prevent the product from floating. |

7 | The continuous Namkeen fryer machine is equipped with an oil circulation filter system, which continuously filters the oil residue during the production process, reduces the acid value of the oil, restores the color of the crude oil, and prolongs the service life of the edible oil by more than 10 times. |

Application Of Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment In 2021

The Application Of Namkeen Snack Fryer Deep Machine | |

Potato chips frying machine; | Tofu frying machine; |

French fries frying machine; | Beans frying machine; |

Walnut frying machine; | Chicken nuggets frying machine; |

Fish frying machine; | Chicken feet frying machine; |

Tofu frying machine; | Peanut frying machine; |

Porkskin frying machine; | Eggplant frying machine; |

Onion rings frying machine; | Samosa frying machine; |

| Namkeen snack deep frying equipment uses the axial fans to blow the surface water of the materials which are conveyed by the stainless steel mesh belt or rubber belt. The more fans namkeen snack deep fryer has, the effect is better.Continuous frying machine automatic fryer namkeen snack deep frying equipment is suitable for draining the surface water of granular and strip products. It's a necessary machine before vegetable freezing, packaging of minimally processing vegetable or frying of fried products. It also can be used for cooling after steam blanching. | |

Customer Cases Of Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment

The company has committed to the research and development of food machinery; the continuous frying machine automatic fryer namkeen snack deep frying equipment was developed after combined of advanced technology at home and abroad and repeated experiments. Now the machinery of the commercial deep fryer Namkeen snack processing line has been exported to singapore, canada, brazil, and western europe, and other countries and regions, promoting the development of the local economy.

Customer Cases For Large Scale Namkeen Snack Frying Line For Factory In 2021 | |

1 | 1000KG/H CE Certificated Industrial Energy Efficient Equipment Snack Frying Automatic Doritos Equipment Sold In Russia Factory |

2 | 5000KG/H Tunnel Type School Namkeen Frying Gas Heated Namkeen Fried Finger Potato Chips Stick Frying French Fries Machine Batch Fryer For Sale In Puerto Rico |

3 | 6000KG/H Hot Selling Multi Function Electric Deep Frier Potato Fryer Machine For Restaurant Frying Equipment In Bolivia |

4 | Senegal 800KG/H Ce Approved Potato Chips Fryer Machine Snacks Frying French Fries Deep Fryer |

5 | 1000KG/H Energy Saving Large Ce Approved Potato Chips Fryer Machine Snacks Frying French Fries Deep Fryer For Sale In Côte d'Ivoire |

6 | America 800KG/H Year Industrial Equipment In Burger King French Fries Chicken Conveyor Belt Continuous Deep Fryer Machine |

Customer Case Of Commercial Deep Fryer Namkeen Snack Processing Line Machinery In 2021 | |

1 | 500kg/h Industrial Continuous Frying Machine Automatic Fryer Namkeen Snack Deep Frying Equipment In Uzbekistan |

2 | 400kg/h Industry Continuous Belt Frying Machine Frying Potato Chips Machine Fried Chicken Equipment In Senegal |

3 | Mozambique 300kg/h Continuous Nut Frying Machine Low Price Professional Automatic Fryer Fried Peanut Production Line |

4 | Bangladesh 200kg/h Fully Continue Equipment Frying Ly-1800c Automatic Continue Food Processing Equipment Vacuum Frying Machine For Sale |

5 | 600kg/h Thai Frying Continuous Frying Machine Commercial Fryer Pressure Snack Continuous Frying Machine |

6 | Uzbekistan 200kg/h Frying Industrial Frying Machine Full Automatic Industry Large Fried Potato Chips Fried French Fries Continuous Frying Machine |