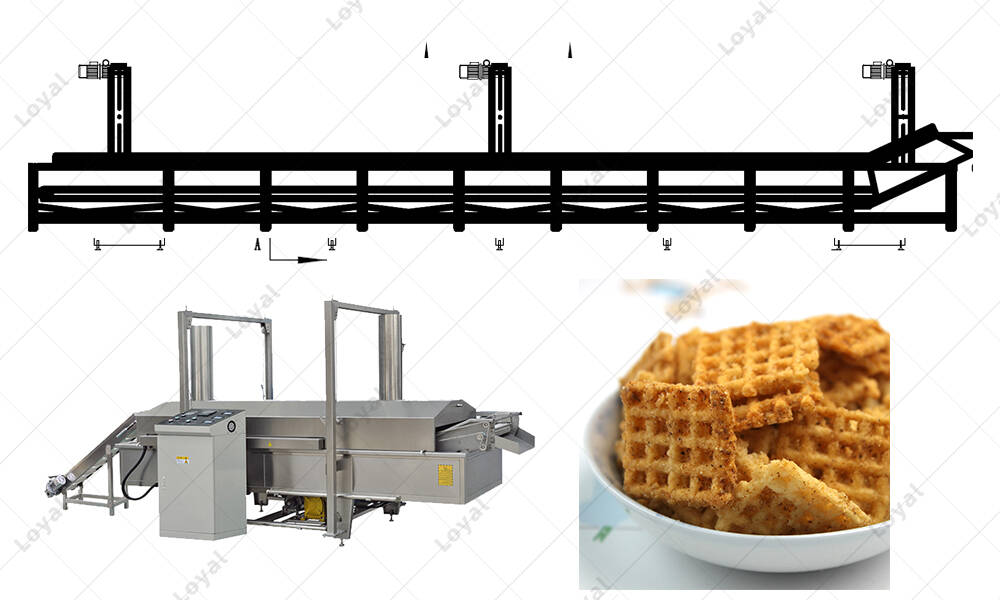

Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant

Loyal is a food machinery manufacturer with years of experience in salad snack fryer development. Loyal industrial automatic continuous salad snack fryer machine frying plant enjoys a high reputation among salad fryer manufacturers and has achieved remarkable results in the manufacture of fryer. Its industrial salad snack fryer is highly cost-effective and has been recognized by many fried food manufacturers.

Industrial salad snack frying machine is designed for automatic working and suitable for different foods; high capacity and high quality and made of SUS304.Frying time and temperature of industrial automatic continuous salad snack fryer machine can be adjusted based on request suitable for different foods.

Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant Specifications :

| Price | Check with Frying Machine Team Saler |

| Model Number | Industrial salad snack frying machine |

| Min.Order Quantity | 1set of Industrial salad snack frying processing line |

| Payment Terms | L/C,D/A,D/P,T/T, |

| Supply Ability | 25Days of Industrial salad snack frying equipment |

| Packaging Details | Film wooden box |

| Team | Professional Fryer Technology Team |

| Sale Team | Fryer Machine Technical Team |

| Process | Ten Years Of Fryer Equipment Manufacturing Process |

Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant Detail Introduction :

Loyal is a food machinery manufacturer with years of experience in salad snack fryer development. Loyal industrial automatic continuous salad snack fryer machine frying plant enjoys a high reputation among salad fryer manufacturers and has achieved remarkable results in the manufacture of fryer. Its industrial salad snack fryer is highly cost-effective and has been recognized by many fried food manufacturers.

Industrial salad snack frying machine is designed for automatic working, suitable for different foods, high capacity and high quality and made of SUS304.Frying time and temperature of industrial automatic continuous salad snack fryer machine frying plant can be adjusted based on request suitable for different foods.

Advantages Of Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant

Advantages Of Industrial Salad Snack Fryer With Temperature Control | |

1 | The industrial salad snack fryer uses the principle of different proportions of oil, water, and animal oil to sink all the residues produced during the working process into the water, and the animal fat sinks into the lower layer of vegetable oil. It fundamentally solves the problem of residues, animal fats, and repeated frying in the traditional frying machine that acidify and carbonize the frying oil and deteriorate and produce carcinogens. |

2 | Continuous salad snack fryer machine can improve quality and ensure health:The special process keeps residues out of the working layer. The heating in the middle can effectively control the convection of the upper and lower oil layers to ensure the purity of various oil layers. |

3 | Industrial automatic continuous salad snack fryer machine frying plant can save frying oil, which is conducive to environmental protectionThe oil-water mixing technology continuously produces a small amount of steam from the water under the oil layer. The central heating process can be adjusted at will according to the needs, and the electric control device can control the upper and lower temperature, which can effectively alleviate the oxidation degree of the fried oil, thereby prolonging the life of the fried oil. |

4 | The oil does not smell, one machine is multi-purpose:The process uses limit control, zone temperature control, and scientific use of the proportion of vegetable oil and animal oil. The animal oil leached from the fried food naturally sinks into the lower layer of the vegetable oil, so that the middle and upper working oil is always pure. |

Technical Parameter Of Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant

Technical Parameter Of Industrial Salad Snack Fryer | |||||

Model | Width Of Belt(MM) | Length(MM) | Heating Method | Power | Capacity |

LY-2500 | 300/400 | 2500 | Electricity/Gas | 36kw | 100kg/h |

LY-3500 | 400/600/800 | 3500 | Electricity/Gas | 48kw | 200kg/h |

LY-4500 | 600/800/1000 | 4500 | Electricity/Gas | 72kw | 300kg/h |

LY-5500 | 600/800/1000 | 5500 | Electricity/Gas | 120kw | 500kg/h |

LY-6500 | 600/800/1000 | 6500 | Electricity/Gas | 144kw | 800kg/h |

LY-8500 | 600/800/1000 | 7500 | Electricity/Gas | 180kw | 1000kg/h |

Application Of Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant

Application Of Industrial Salad Snack Fryer | |

1 | Industrial automatic continuous salad snack fryer machine frying plant is especially suitable for american brand fast food chain stores, theme restaurant, fried chain stores and those who always focus on brand development and pursue top taste. |

2 | Dontinuous salad snack fryer machine can produce fried chicken, french fries, spring rolls, shrimp steak, fillets, doughnuts, Etc. |

Which Market Did The Loyal Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant Sold?

LOYAL's share of industrial continuous salad snack fryer exported to international markets has steadily increased. According to the export goods trade data in 2021. LOYAL's export market share in the international market is 86.5%, of which the PLC control continuous salad snack fryer export market share is 19.8%, the export market share in the Americas is 31.2%, and the export market share in Asia is 35.5%. If you are interested in a meat dryer, please contact us today, we offer you the most cost-effective solution.

Customer Have Formula Request Of Continuous Salad Snack Fryers Manufacturers | |

1 | America 500KG/H Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant |

2 | 200KG/H PLC Control Continuous Salad Snack Fryer For Sale In Puerto Rico |

3 | 300KG/H Industrial Continuous 3DPellet Snack Fryers For Sale In Bolivia |

4 | 800KG/H Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant For Sale In Argentina |

5 | 100KG/H Fully Automatic Industrial Continuous Salad Snack Fryers For Sale In Benin |

6 | 500KG/H PLC Control Fully Automatic Industrial Continuous Salad Snack Fryers For Sale In British Indian Ocean Territory |

7 | 200KG/H PLC Control Fully Automatic Industrial Continuous 3DPellet Snack Fryers For Sale In Chile |

Cooperated Customer For Laboratory Machine Of PLC Control Salad Snack Fryers | |

1 | Senegal 200KG/H Industrial Continuous Salad Snack Fryers |

2 | 100-200KG/H Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant In India |

3 | 300-400KG/H Industrial Continuous Salad Snack Fryer For Sale In Sold In Russia |

4 | 500KG/H Industrial Continuous Potato Chips Snack Fryer For Sale In Sold In Denmark |

5 | 600KG/H PLC Control Continuous Salad Dough Snack Fryer For Sale In Dominica |

6 | 100-200KG/H Industrial Continuous 2D Pellet Snack Fryer For Sale In Egypt |

7 | 300-400KG/H Industrial Continuous Salad Snack Fryer For Sale In Sold In Ethiopia |

Cooperated Customer Request Engineer Installation In 2021 | |

1 | 300KG/H PLC Control Continuous Salad Snack Fryer For Sale In Uzbekistan |

2 | 100KG/H Industrial Fully Automatic 2D Pellet Snack Processing Line For Sale In Senegal |

3 | Mozambique 400KG/H Fully Automatic Potato Chips Processing Line |

4 | 200KG/H Thai PLC Control Continuous Salad Snack Fryers |

5 | Uzbekistan 100KG/H PLC Control Continuous Salad Snack Fryer |

6 | 500KG/H Fully Automatic Pasta Processing Line For Sale In Germany |

7 | 200KG/H Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant For Sale In Guinea |

Cooperated Customer With Fully Automatic Salad Snack Line Technology In 2021 | |

1 | Nigeria 500KG/H Industrial Automatic Continuous Salad Snack Fryer Machine Frying Plant |

2 | Austria Sells Fully Automatic Industrial Continuous Salad Snack Fryers 1000KG/H |

3 | Industrial Continuous Salad Snack Fryer For Sale In Pakistan 100KG/H |

4 | 100KG/H Fully Automatic Industrial Continuous Salad Snack Fryers Line For Sale In India |

5 | 200KG/H Industrial Continuous Salad Snack Fryers For Sale In Israel |

6 | 200KG/H PLC Control Continuous Salad Snack Fryers For Sale In Jamaica |

7 | 200KG/H PLC Control Continuous Salad Snack Fryer For Sale In Morocco |