Multi-Functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System

As a professional full automatic deep orchid beans frying machine manufacturer, our loyal multi-functional stainless steel commercial orchid beans frying machine with oil filtration system is the reliable equipment to choosing for many food manufacturing plant. Our loyal industry plant provides customers full set service, like cost accounting, commercial continuous deep fryer design, frying machine installation and debugging according to customer requirements. This kind of industrial fryer oil filtration systems also can fry a french fries, onion rings, peanuts and pellet snacks and so on.

Multi-Functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System Specifications :

| Brand Name | LOYAL Fryer Sterilization Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set |

| Supply Ability | 25Days of Commercial orchid beans frying machine |

| Packaging Details | Export-compliant frying equipment packaging |

| Honor | A Number Of National Fryer Equipment Patents |

| Technology | 8 Years Of Fryer Technology |

Multi-Functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System Detail Introduction :

Commercial continuous deep fryer for orchid beans can fry continuously with consistent quality in automatic orchid beans making lines. As a result, multi-functional stainless steel commercial orchid beans frying machine with oil filtration system is suitable for large scale food making plant which need great production capacity. Besides, due to its robust design with stainless steels, the continuous chips frying machines can work for long times non-stop. Built with advanced technology, our loyal designed continuous mesh belt frying machine can ensure constant high temperature of oil and allow you to adjust frying time according to your needs. Besides, the multi-functional stainless steel commercial orchid beans frying machine with oil filtration system are specially designed to save water, oil and energy during the frying process.

How To Fry Orchid Beans?

Orchid Beans is deeply loved by both domestic and foreign friends. Due to regional problems, the tastes vary from place to place. Before starting production, multi-functional stainless steel commercial orchid beans frying machine with oil filtration system is best to choose the new broad beans of the year. The grains are full, uniform in size, intact, and the bad broad beans with mildew and black spots are removed. Wash them with water to remove impurities. Frying is the main practice of orchid beans. Most manufacturers will use continuous fryers for production.

The Steps Of Starting The Commercial Continuous Deep Fryer |

1. Add oil to the fryer until it is above the non-stick pan. |

2. Press the heating power control switch on the power distribution cabinet. |

3. According to the production needs, then the person in charge of the equipment sets the oil temperature parameters of the fryer. |

4. Turn on the slag scraper control power supply and filter oil, circulating pump system. |

5. When the oil temperature rises above 150 ℃, start A mesh belt, then the B non-stick pan and oil supply power control. |

At the end of multi-functional stainless steel commercial orchid beans frying machine with oil filtration system production, notify the oil furnace to turn off the heating system 10 minutes in advance. Also notify refrigeration to stop cooling 10 minutes in advance. |

Technical Parameter Of Multi-functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System

Technical Parameter Of The Full Automatic Deep Fryer Machine | ||||

Frying Equipment Mode | Heating Power | Heating Temperature | Output | Size (L*W*H) |

LY-L(electric fryer) | 97kw/h | ~250℃ | 300kg/h | 3000x1200x2100mm |

LY-G (Gas/Diesel) | 6-20.5m³/h(Gas);7-15kg/h(Diesel) | ~250℃ | 300kg/h | 3000x1200x2100mm |

LY-L-2 (electric fryer) | 122kw/h | ~250℃ | 400-500kg/h | 4000x1300x2200mm |

LY-G-2 (Gas/Diesel) | 35m³/h(Gas);8-41kg/h (Diesel) | ~250℃ | 400-500kg/h | 4000x1300x2200mm |

ABB Motor Of Multi-functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System

Abb Motor Of Automatic Deep Orchid Beans Frying Machine | |

Package Level /1 Units | 0 Carton |

Product Name | 3-Phase Squirrel Cage Motor |

Product Net Weight | 5.9 Kg |

Product Type | 3Aa2__M3Aa_Ie2_Aa |

Scip | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (Fi) |

Selling Unit Of Measure | Piece |

Standards | Iec 60034-1 |

Starting Of Motor | Direct Online |

Why To Choose Multi-functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System?

The Features Of The Continuous Mesh Belt Frying Machine | |

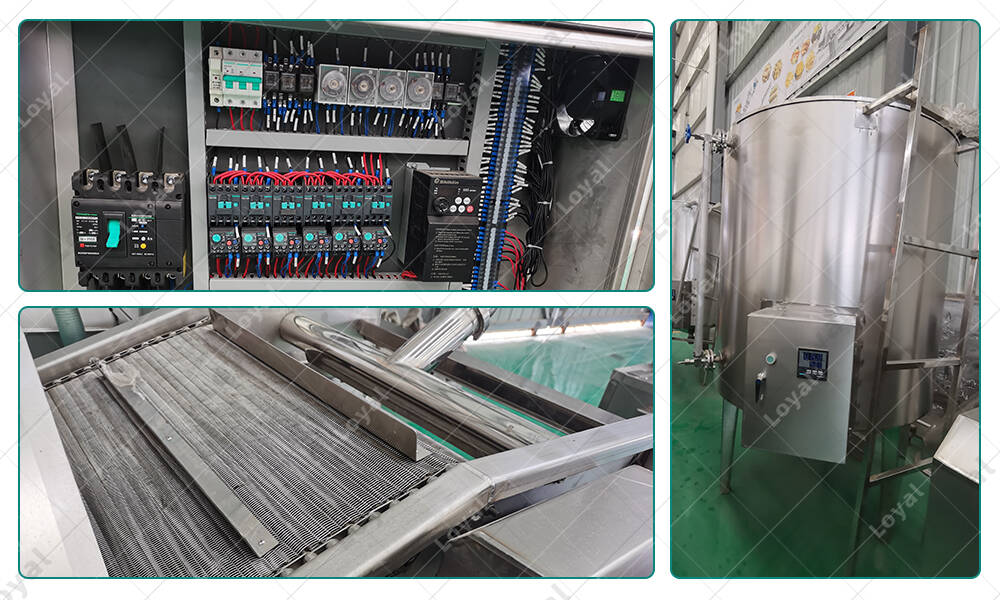

1 | Multi-functional stainless steel commercial orchid beans frying machine with oil filtration system has brand electronic apparatus ensure the excellent and stable performance. |

2 | Controller box made of stainless steel or sprayed-plastic(optional), allows adjust frying time by variable conveying speed as required, alarm oil Level. |

3 | Electric belt and upper cover lifting setting, make cleaning more easier and save human power. |

4 | Different heating methods optional: electricity, LPG, natural gas, diesel etc. |

The Advantages Of The Industrial Fryer Oil Filtration System | |

1 | Multi-functional stainless steel commercial orchid beans frying machine with oil filtration system adopts "water-oil separator" which can keep the oil clean and continuous working. The oil and water temperature can be controlled automatically. |

2 | Frying all kinds of foods without the Taint of odor. No oil smoke, Frying machine can ensure the health of the operator. |

3 | With characteristics of controlling the temperature automatically, even heating, Frying machine can keep stable temperature and the nutrition of frying foods. Easy operation, one person can operate it. |

4 | Made of 304 stainless steel materials, with long service life and can reach the hygiene standard. |

What Is The Application Of The Multi-Functional Stainless Steel Commercial Frying Machine?

The Applications Of The Continuous Mesh Belt Frying Machine | |

| Cooked Wheaten Food | Fried dough twist, rice crust, honey food, deep-fried dough sticks. Also fried glutinous rice balls with sesame, gluten, polished glutinous rice stick, caramel treats, thin fried dough twist, etc. |

Meat | Braised chicken (coloring), pressed salted duck (coloring), braised pork, ball, sliced dried beef, streaky pork, drumstick and pig's feet, etc. |

Nut Fruits | Groundnut kernels, green soya bean, broad bean, sunflower seed. |

Bean Products | Dried tofu, bean curd, fish bean curd, bread made by tofu. |

Marine Food Products | Multi-functional stainless steel commercial orchid beans frying machine with oil filtration system can fry various fish, peeled prawns, scallop, fish, squid rings, squid. |

What Kind Of Multi-Functional Stainless Steel Commercial Frying Machine Sale By Loyal In 2021

Customer Case Of The Automatic Continuous Frying Machine In 2021 | |

1 | 500kg/h Multi-functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System For Sale Thailand |

2 | Large Capacity Automatic Conveyor Belt ContinuousFryer 2d Snack Pellet Frying Machinefor Sale Sudan |

3 | 200kg/h Conveyor Continuous Deep Fryer Machine Potato Chips Fryer Machine For Sale Burkina Faso |

4 | 600kg/h Continuous Fryer Fried Dough Frying Machine For Sale Australia |

Customer Case Of Commercial Continuous Deep Fryer At Discount Prices In 2021 | |

1 | 500kg/h Electric Fried Chips Deep Air Continuous Fryer Machine For Sale Mozambique |

2 | 1000 kg/h Pellet Snacks Machine Continuous Deep Fryer Machine For Sale Austria |

3 | Automatic Fish Continuous Deep Fryer Machines For Sale Moldova |

4 | 250kg/h Full Automatic Nuggets Burger Continuous Deep Fryer Machines For Sale Ukraine |

5 | Auto Crispy Onion Fryer And Frying Machine With Continuous Filtration System For Sale Singapore |

Repurchase Case Customer With Industrial Fryer Oil Filtration Systems Technology In 2021 | |

1 | Continuous Fryer Frying Machine Tortilla Chips Deep Fries Machines For Sale America |

2 | 300kg/h Automatic Potato Chips Continuous Fryer Frying Cooking Machine Sale To Bolivia |

3 | 700kg/h PLC Control Industrial Continuous Belt Deep Frying Equipment Conveyor Fryer Machine For Sale Dominica |

4 | Large Capacity Multi-functional Stainless Steel Commercial Orchid Beans Frying Machine With Oil Filtration System For Sale In Senegal |

5 | 3D Snacks Pellet Chips Continuous Belt Deep Frying Equipment Price In Nigeria |

Transaction Case Customer Of Continuous Frying Machine Machine In 2021 | |

1 | Continuous Automatic Gas Chin Chin Belt Frying Oil Fryer Machine For Sale Thailand |

2 | 500kg/h Automatic Continuous Chips Pellet Snack Deep Fryer Machine For Sale UK |

3 | 100kg/H Chicken Chop Tempura Shrimp Squid Rings Continuous Fryer Frying Machine For Sale Myanmar |

4 | Continuous Automatic Nuts Belt Frying Oil Fryer Machine For Sale With New Technology To Vietnam |

5 | Automatic Snacks Food Potato Chips Fryer Continuous Frying Machine For Sale Zimbabwe |

6 | 600kg/h Continuous Automatic Gas Banana Chips Belt Fryer Machine For Sale Turkmenistan |