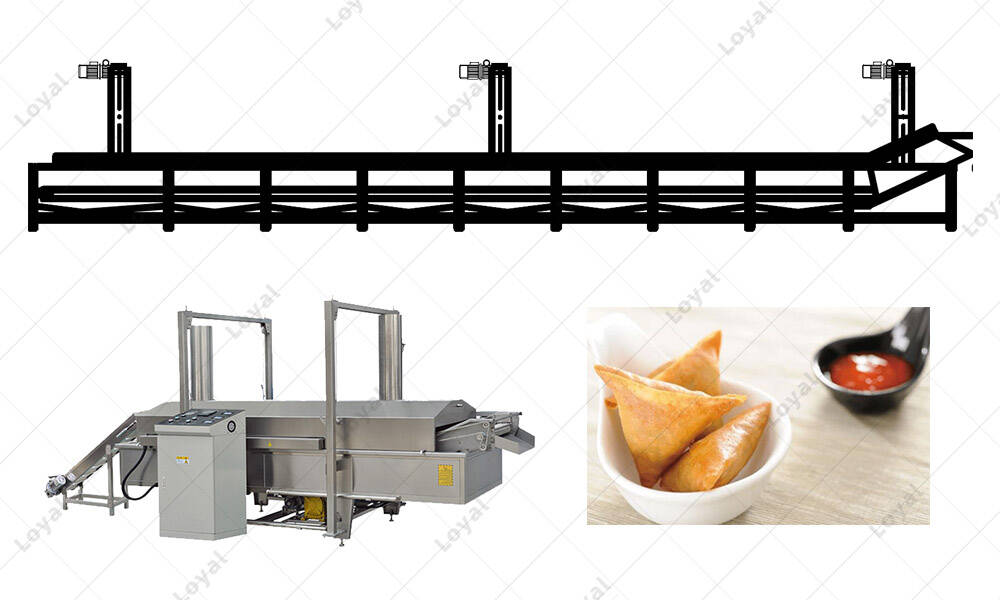

High Quality Automatic Fryer for Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine

Loyal high quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine is fully automatic and can process and produce all types of gas fryer continuous Samosa machine . Gas fryer continuous Samosa machine has high production efficiency and a wide range of applications, and has become a trusted equipment for gas fryer continuous Samosa machine manufacturers.

Now Samosa have become the first choice of snacks for the public, and almost every class of people likes Samosa, so the Samosa market has a bright future. If you also want to get a better development in the Samosa industry, loyal fryer continuous Samosa machine will be your ideal choice.

Shandong Loyal has established a complete service system for continuous Samosa fryer machine, providing manufacturers with high-quality and low-cost biscuit equipment, and at the same time providing complete after-sales service of continuous Samosa frying machine.

High Quality Automatic Fryer for Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine Specifications :

| Price | Check With Frying Machine Team Saler |

| Model Number | Continuous Fryer Samosa Machine |

| Place of Origin | China |

| Payment Terms | D/A, |

| Supply Ability | 25Days of Continuous Fryer Samosa equipment |

| Delivery Detail | 20days--35days |

| Packaging Details | Export-compliant microwave equipment packaging |

| Honor | A Number Of National Fryer Equipment Patents |

| Process | Ten Years Of Fryer Equipment Manufacturing Process |

| Technology | 8 Years Of Fryer Technology |

High Quality Automatic Fryer for Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine Detail Introduction :

Commercial Samosa continuous frying machine is fully made of stainless steel material which is good to health and easy to maintain. Automatic Samosa fryer is one of our CE certificate product.This continuous fryer Samosa machine food fryer works with electricity power as its heating source, manual discharging, automatic mixing, operating is simple. High quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine works based on full oil technology. The continuous fryer Samosa machine food fryer machine is made of high quality stainless steel material, exquisite workmanship, strong and durable.Temperature controlling is automatic, meanwhile, also separates the inferior oil, totally is safe and easy cleaning.

How To Choose High Quality Automatic Fryer For Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine?

The Models Of Gas/Diesel Fryer Continuous Fryer Samosa Machine Food Fryer machine | ||||

Model | Electric (Gas/Diesel) Consumption | Output | Heating Temperature | Dimensions |

LY-1 | 60kw | 300kg/h | 250°C | 3000x1200x2100mm |

LY-2 | 96kw | 400-500kg/h | 250°C | 4000x1300x2200mm |

LY-3 | 20.5 m8/h(Gas);15kg/h(Diesel) | 300kg/h | 250°C | 3000x1200x2100mm |

LY-4 | 35m8/h(Gas);8-41 Kg/h(Diesel) | 400-500kg/h | 250°C | 4000x1300x2200mm |

LY-5 | 45kw | 60-80kg/h | 250°C | 2000x1500x2100mm |

Working Principle For High Quality Automatic Continuous Fryer Samosa Machine Food Fryer Machine?

High quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine uses heat-conducting oil burning furnace and selects cycle heating style, it can adopt many kinds if energy such as coal burning, gas burning and oil burning.High quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine selects and uses optimized structure, reduces oil filling, and has high turnover rate of frying oil.

During the frying process, automatic Samosa fryer introduces developing filtering system, which can remove the residue quickly, keep the oil fresh all the time, completely solve the problem of edible oil going bad, environment protecting sanitation, energy and cost.

Configuration of high quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine: automatic oil-temperature controlling system, hydraulic lifting system, guipure transferring system, heating system, automatic filtering system.

Technical Parameters Of High Quality Automatic Continuous Fryer Samosa Machine Food Fryer Machine

Technical Parameters And Price Of Continuous Fryer Samosa Machine Food Fryer Machine | |||

Type: | Frying Oven | Application: | Fryer Machine |

Condition: | New | Place Of Origin: | Shandong, China |

Brand Name: | LY | Voltage: | 380v/440v Customized |

Power: | 20-200kw | Dimension(L*W*H): | 8640 *1200* 2200mm |

Key Selling Points: | High Productivity | Warranty: | 1 Year |

Applicable Industries: | Food & Beverage Factory, Farms, Food & Beverage Shops | Marketing Type: | Ordinary Product |

Machinery Test Report: | Provided | Core Components: | Motor, PLC |

Motor Brand: | Siemens | Price | 4500USD--20000USD |

Siemens Motor Of CHigh Quality Automatic Continuous Fryer Samosa Machine Food Fryer Machine

Siemens Motor Of Continuous Fryer Samosa Machine Food Fryer machine | ||

1 | Package Level 1 Units: | 0 Carton |

2 | Product Name: | 3-Phase Squirrel Cage Motor |

3 | Product Net Weight: | 5.9 Kg |

4 | Product Type: | 3Aa2__M3Aa_Ie2_Aa |

5 | Scip: | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (Fi) |

6 | Selling Unit Of Measure: | Piece |

7 | Standards: | IEC 60034-1 |

8 | Starting Of Motor: | Direct Online |

The Layout of High Quality Automatic Continuous Fryer Samosa Machine Food Fryer Machine

Automatic continuous Samosa frying machine is made of food grade stainless steel, consists of lifting system, conveying system, gas heating system, blowdown system, oil circulation system, smoke exhaust system and electric control system.

The Application Of High Quality Automatic Continuous Fryer Samosa Machine Food Fryer Machine

The Application Of Continuous Samosa Fryer Machine | |

Potato chips frying machine; | Tofu frying machine; |

French fries frying machine; | Beans frying machine; |

Walnut frying machine; | Chicken nuggets frying machine; |

Fish frying machine; | Chicken feet frying machine; |

Tofu frying machine; | Peanut frying machine; |

Porkskin frying machine; | Eggplant frying machine; |

Onion rings frying machine; | Samosa frying machine; |

Features&Advantages of High Quality Automatic Continuous Fryer Samosa Machine Food Fryer Machine

Features&Advantages of Continuous Fryer Samosa Machine Food Fryer machine | |

1 | Frying machine is suitable for continuous food production with high output. |

2 | The products are layered between upper and lower mesh belt so as to avoid floating when they are fried in frying oil. |

3 | The transmission system of the frying machine is designed as frequency stepless speed regulation, this can help the operator to control the frying time freely. |

4 | The high quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine is equipped with automatic lifting system, help the mesh belt to be cleaned more easily. |

5 | Automatic scraping system can continuously take away the oil residue produced in the frying process from the bottom, this can keep the frying oil clean and extend the service life of frying oil. |

6 | Multi group temperature control system, can save more electricity consumption. |

7 | High quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine has unique temperature control panel, make operating easy, simple and safe. |

Which Market Did The Loyal Industrial Continuous Fryer Samosa Machine Food Fryer machine?

Customer Have Formula Request Of Continuous Fryer Samosa Machine Manufacturers | |

1 | India 300KG/H High Quality Automatic Fryer for Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine |

2 | 200KG/H PLC Control Continuous Fryer Samosa Machine For Sale In Puerto Rico |

3 | 300KG/H Industrial C Continuous Fryer Samosa Machine For Sale In Bolivia |

4 | 800KG/H High quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine In Argentina |

5 | 1000KG/H Fully Automatic Industrial Continuous Dough Snack Fryers For Sale In Benin |

6 | 500KG/H PLC Control Automatic Industrial Continuous Dough Snack Fryers For Sale In British Indian Ocean Territory |

7 | 200KG/H PLC Control Fully Automatic Industrial Continuous Pellet Snack Fryers For Sale In Chile |

Cooperated Customer For Laboratory Machine Of Plc Control Continuous Fryer Samosa Machine | |

1 | Senegal 200KG/H High Quality Automatic Fryer for Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine |

2 | 100-200KG/H Industrial Continuous Dough 3D Snack Fryer For Sale In Côte d'Ivoire |

3 | 300-400KG/H Industrial Continuous 2D Pellet Snack Fryer For Sale In Sold In Russia |

4 | 500KG/H Industrial Continuous Dough Snack Fryer For Sale In Sold In Denmark |

5 | 600KG/H Plc Control Continuous Dough Snack Fryer For Sale In Dominica |

6 | 100-200KG/H Industrial Continuous Samosa Snack Fryer For Sale In Egypt |

7 | 300-400KG/H Industrial Continuous Dough Snack Fryer For Sale In Sold In Ethiopia |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 300KG/H PLC Control Continuous Dough Snack Fryer For Sale In Uzbekistan |

2 | 100KG/HHigh Quality Automatic Fryer for Sale Gas Continuous Fryer Samosa Machine Food Fryer Machine In Senegal |

3 | Mozambique 400KG/H Fully Automatic Samosa Processing Line |

4 | 200KG/H Thai PLC Control Continuous Dough Snack Fryers |

5 | Uzbekistan 100KG/H PLC Control Continuous Dough Snack Fryer |

6 | 500KG/H High Quality Automatic Fryer Continuous Fryer Samosa Machine Food Fryer Machine In Germany |

7 | 200KG/H Fully Automatic Samosa Processing Line For Sale In Guinea |

Cooperated Customer With Fully Automatic Dough Snack Line Technology At 2021 | |

1 | Nigeria 500KG/H Fully Automatic Dough Snack Line |

2 | Austria Sells Fully Automatic Industrial Continuous Dough Snack Fryers 1000KG/H |

3 | Industrial Continuous Dough Snack Fryer For Sale In Pakistan 100KG/H |

4 | 300KG/H Fully Automatic Industrial Continuous Samosa Fryers Line For Sale In India |

5 | 500KG/H Industrial Continuous Dough Snack Fryers For Sale In Israel |

6 | 200KG/H Plc Control Continuous Dough Snack Fryers For Sale In Jamaica |

7 | 600KG/H Plc Control Continuous Samosa Fryer For Sale In Morocco |

FAQ:

Should samosas be deep fried?

Asmosa frying is the correct method, because during the frying process, the samosa fillings can be locked in the fragrance, crispy on the outside and tender on the inside, which is welcomed by many people.

What oil do you fry samosas in?

Regarding the use of some, Loyal high quality automatic fryer for sale gas continuous fryer Samosa machine food fryer machine is best to use the oil according to the local custom, which is more consistent with the local taste and easier for people to accept.