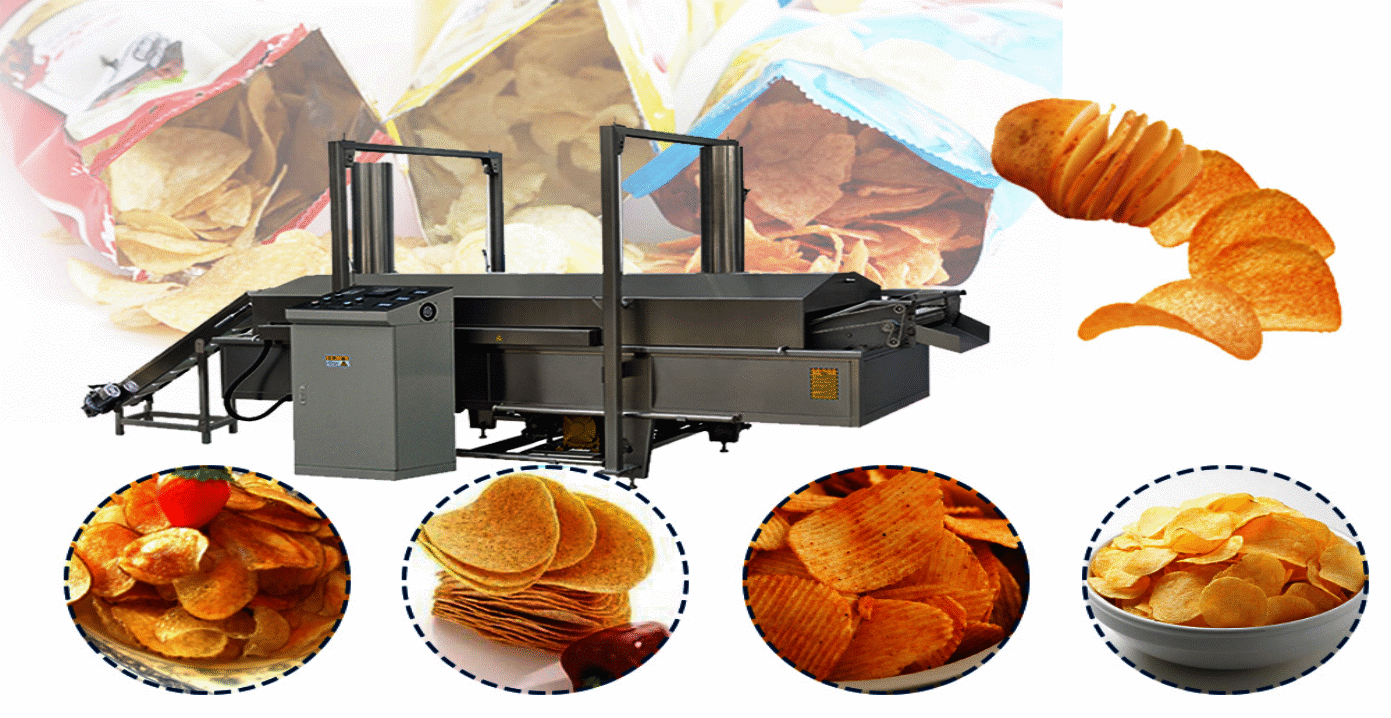

Automatic Potato Chips Processing Plant

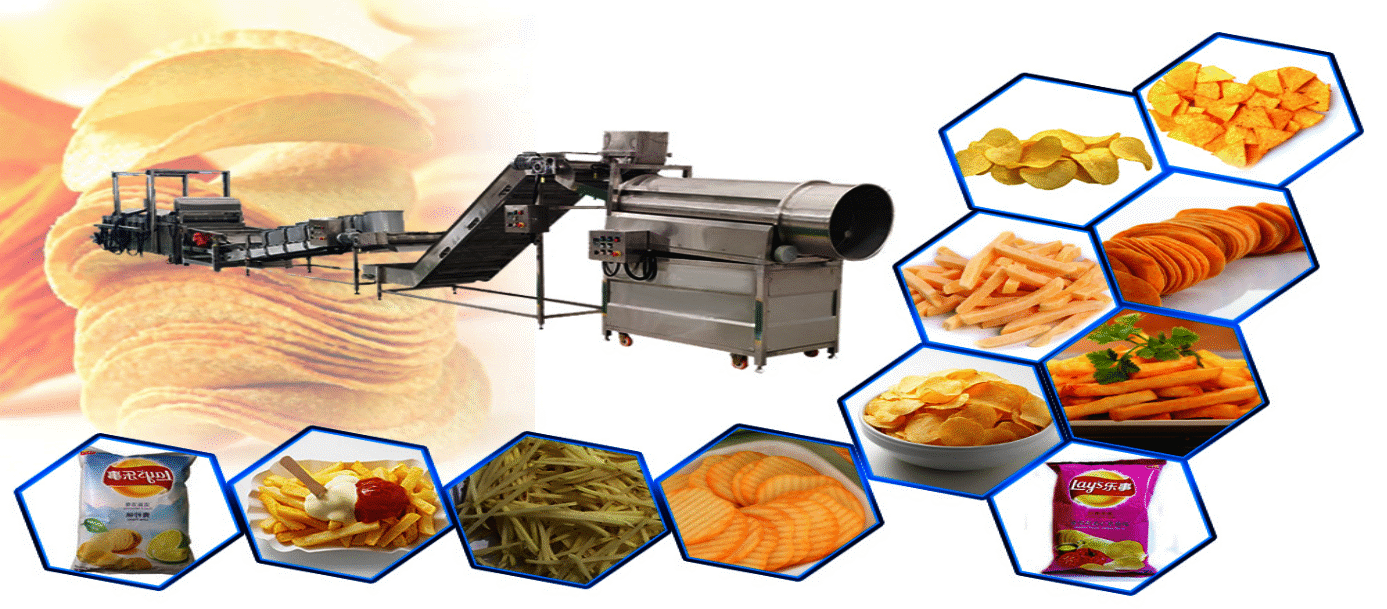

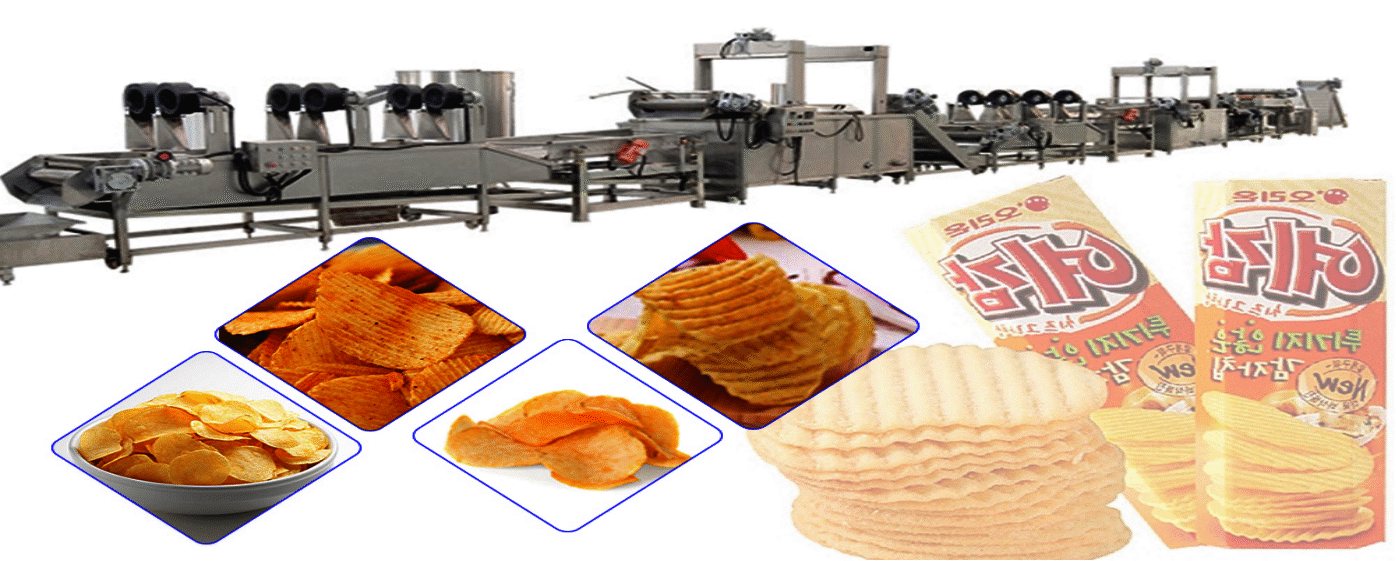

One of the largest fried potato chips making machine manufacturer, the loyal fully automatic potato chips line have been exported to the United Kingdom, Singapore, Canada, Brazil, Western Europe and other 116 countries and regions, promoting the development of the local economy. Automatic potato chips processing plant has the advantages of low one-time investment, low energy consumption, multiple functions, small size, high profit, and convenient use and maintenance. The potato chip line has high yield and saves manpower. Automatic potato chips making machine is designed for making the potato chips &frozen french fries. Raw materials can be fresh potato, fresh cassava etc. Through the washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips. After flavoring with the flavor powder can get many kinds of taste of delicious chips. This potato chip plant is mainly used for processing the potato strips and chips. The complete potato chip line for sale above is made of stainless steel for sale.

Automatic Potato Chips Processing Plant Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| MOQ | 1 set/ Potato Chips Making Machine |

| Keywords | Potato Chips Making Machine |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Application fields | Potato chips processing plant,supermarket,vegetables |

| Material | Stainless Steel |

| Place of Origin | Shandong, China |

Automatic Potato Chips Processing Plant Detail Introduction :

What Is The Potato Chips Production Line ?

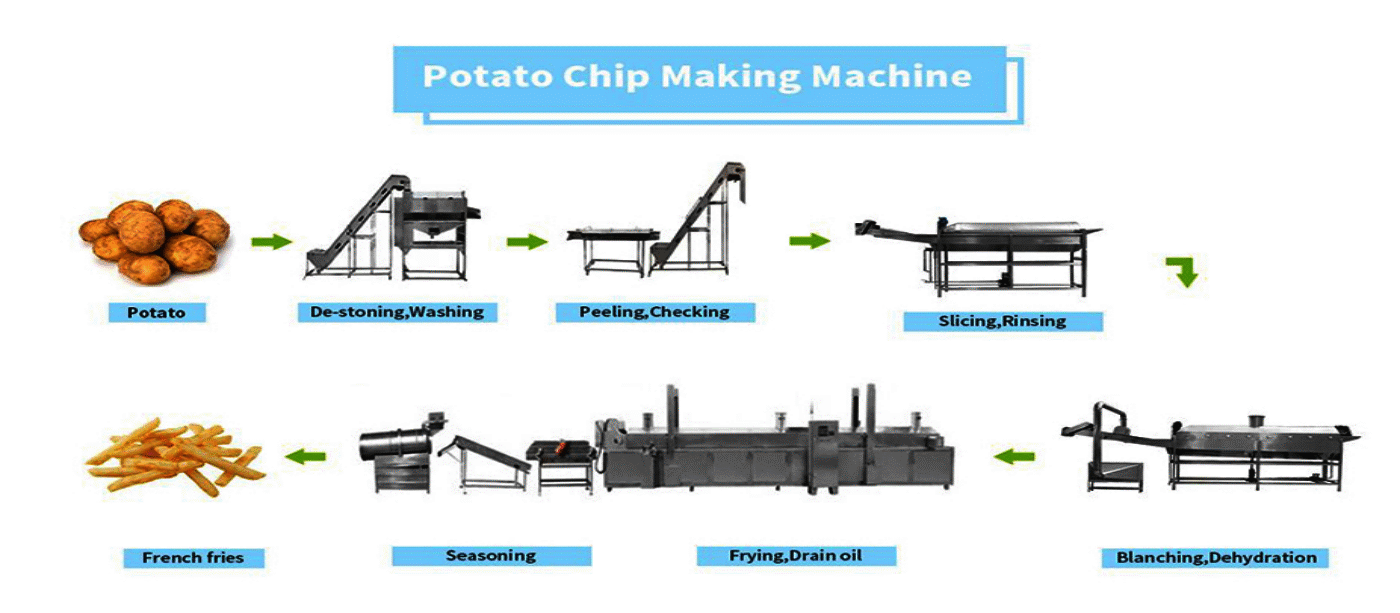

The automatic potato chips processing plant consists of washing and peeling, slicing (stripes), blanching, dehydration, frying, seasoning, packaging and auxiliary equipment. Potato chips manufacturing plant cost widely applies to processing the fresh potatoes into the potato strips and chips. This potato chips making machine is sold at home and abroad. The new and old customers are welcome for potato chips manufacturing plant price.The industrial potato chip line has high yield and saves manpower.This potato chip plant is mainly used for processing the potato strips and chips. The complete potato chips line for sale above is made of stainless steel.

What Kind Of Machines Are Used To Make Potato Chips?

Production Process Of Automatic Potato Chips Processing Plant | |||

| 1 | Raw Material Preparation | 2 | Potato Chip Washing Machine |

| 3 | Potato Chip Peeling Machine | 4 | Checking Machine |

| 5 | Potato Chip Slicing Machine | 6 | Rinsing Machine |

| 7 | Blanching Machine of Potato Chip Plant | 8 | Conditioning Machine |

| 9 | Potato Chip Drying Machine | 10 | Potato Chip Frying Machine |

| 11 | Oil Draining Machine | 12 | Potato Chip Flavoring Machine |

Flow chart of the automatic potato chips plant: The Raw Material----Washing And Peeling ----Selecting And Trimming ----Improve The Input Material----Slicing (Strip)----Rinsing----Blanching ---Dehydration ---- Frying Of Potato Chips Manufacturing Plant Price ---- De-Oiling ---- Seasoning ---- Cooling ---- Packaging | |||

This set of Industrial potato chips equipment is made of 304 stainless steel, with high output and labor saving. And the potato chips processing plant is installed and debugged on site. | |||

Why Choose The Loyal Potato Chips Plant?

The Reason Why to Choose Loyal Semi Automatic Potato Chips Making Line | |

| 1 | We are the potato chips manufacturer, not trading company, it can ensure best quality best price. |

| 2 | Over 10 years experience, mature technology machines of potato chips plant price . |

| 3 | We supply engineers and professional overseas service to guide installation and train. |

| 4 | 1 year free warranty and lifetime warranty of potato chips making plant for our customers |

| 5 | We design the special proposal design for every customer to supply the best suitable potato chips plant price products. |

| 6 | We approve customer come to potato chips manufacturing plant cost factory and workshop to visit and guide. |

| 7 | If customer need, we can supply videos and pictures before visiting. |

What Is Technical Parameter Of Potato Chips Automatic Plant Cost?

Technical Parameter Of Potato Chip Making Line | ||||

Model of potato chip processing line | Powder | Dimension of potato chip making plant | Weight | Capacity |

LY-100 | 1.1kw/380v | 1540*730*740mm | 220kg | 100kg/h |

LY-200 | 2.2kw/380v | 2120*840*900mm | 300kg | 200kg/h |

LY-300 | 2.6kw/380v | 2400*840*900mm | 380kg | 300kg/h |

LY-500 | 3.0kw/380v | 2550*840*900mm | 400kg | 500kg/h |

ABB Motor Of Full Automatic Potato Chips Making Processing Line | ||

| 1 | Package Level 1 Units | 0 carton |

| 2 | Product Name | 3-Phase squirrel cage motor |

| 3 | Product Net Weight of Automatic Potato Chips Making Plant | 5.9 kg |

| 4 | Product Type | 3AA2__M3AA_IE2_AA |

| 5 | SCIP of Potato Chips Processing Plant | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

| 6 | Selling Unit of Measure | piece |

| 7 | Standards of Potato Chips Automatic Plant Cost | IEC 60034-1 |

| 8 | Starting of Motor | Direct Online |

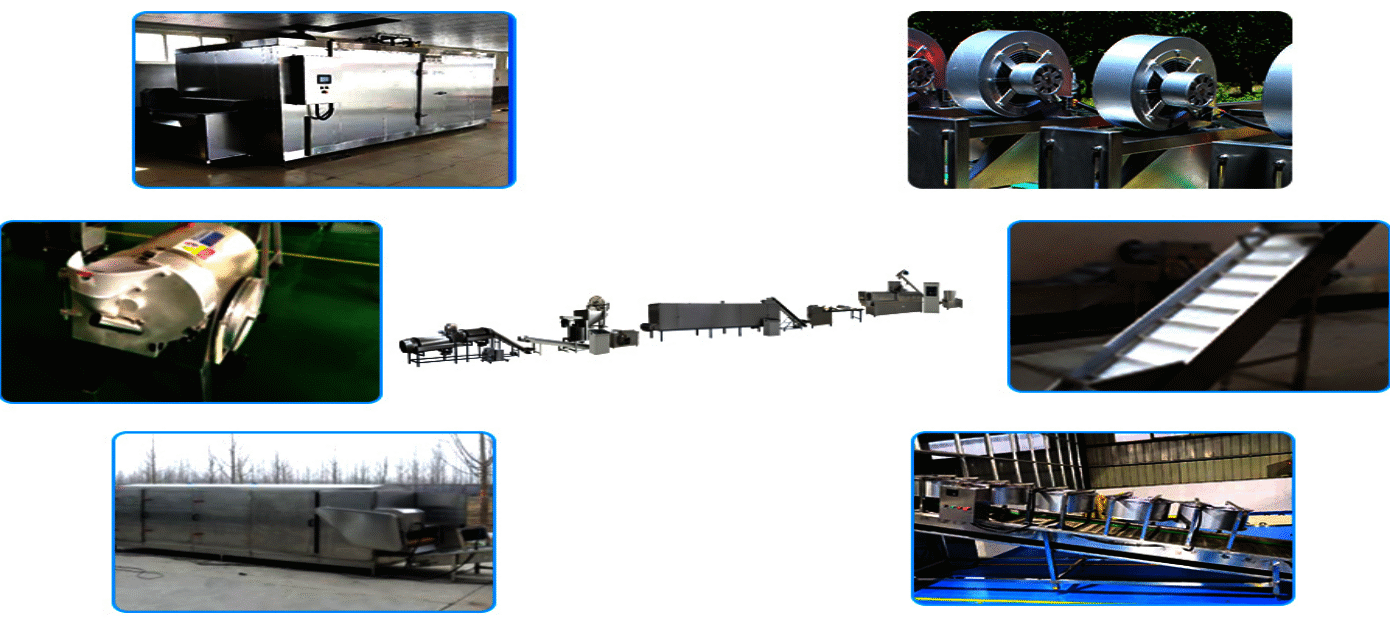

Detailed Picture:

How Much Does It Cost To Make Potato Chips In Potato Chips Processing Plant ?

Full Automatic Potato Chips Plant Machine Price Cost | |||

Model Of Potato Chip Line | Chips Plant Machinery Cost | Capacity | Dimension Of Automatic Potato Chips Plant |

LY-100 | 20000-63500Usd | 100kg/h | 1540*730*740mm |

LY-200 | 63500-90000Usd | 200kg/h | 2120*840*900mm |

LY-300 | 90000-110000Usd | 300kg/h | 2400*840*900mm |

The Potato Chips Production Line Price Is The Promote Price In 2022. Updated Price Pls Check With Our Chip Snacks Food Machine Line Team. | |||

What Is Main Equipment Of Potato Chips Manufacturing Plant?

Main Equipment Of Commercial Potato Chips Manufacturing Plant | ||

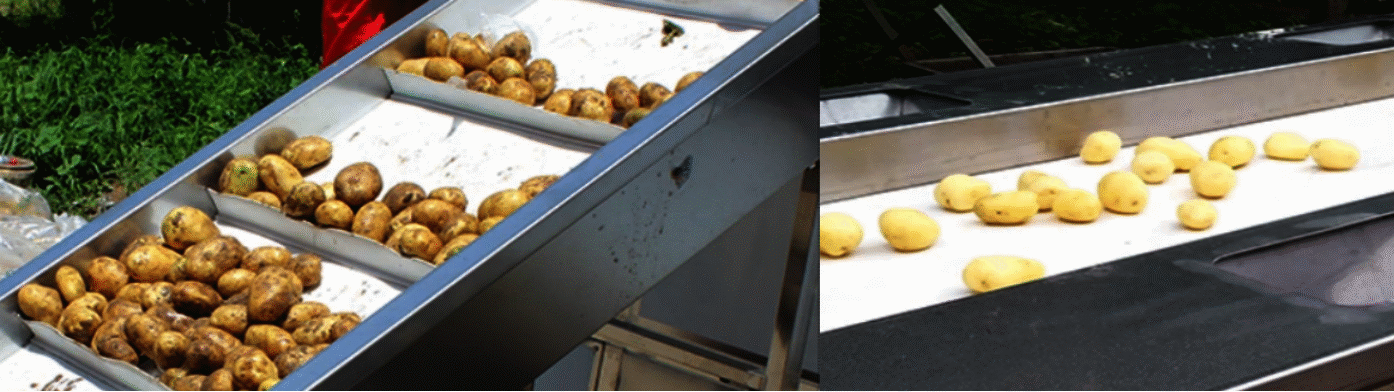

| 1 | Peeling Machine | The potatoes shall be washed and peeled by the potato washing and peeling machine. |

| 2 | Potato Chips Slicing Machine | The peeled potatoes are cut into strips by the super-speed slicing machine of automatic potato chips processing plant. |

| 3 | Rinsing Machine | Put the potato strips into the ozone disinfection vegetables washing machine and rinse out the mucus on the surface. |

| 4 | Potato Chips Blanching Machine | After rinsing, put the potato strips into the blanching machine of small scale potato chips manufacturing plant for inactivating the oxidase in potato strips, Preventing color deterioration and accelerating dehydration. |

| 5 | Vibration draining Machine | After blanching, put the potato strips into the vibration draining machine for removing the excessive moisture. |

| 6 | Deep frying machine of potato chips plant for sale | After dehydration, the potato strips will be conveyed into the frying machine of used potato chips plant for sale for deep frying by the lifting conveyor. |

| 7 | De-oiling Machine | After de-oiling processing of potato chips manufacturing plant by the air drying and lifting machine, the fried potato strips is sent to the spices mixing machine for flavoring. |

| 8 | Seasoning Machine of potato chips plant machine price | The spice mixing machine is provided with the dip type seasoning drum which can automatically control the rotate speed and capacity of materials. The chips plant machinery cost is equipped with automatic feeding device and the feeding capacity is adjustable. It can fully mix the potato strips with the spices. |

| 9 | Potato Chips Weighing and packing Machine | After seasoning, the potato stripes are conveyed by lifting conveyor to the packing machine of potato chips making plant for vacuum packing or normal packing. The weighing device may be provided if it is necessary. |

How About The Raw Material And Finished Potato Chips Product?

We are a leading manufacturer and exporter of potato chips equipment, snack food machines and packaging machines, designed to meet our customers' specific requirements.our automatic potato chips processing plant project using fresh potatoes as raw materials, the whole process of washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips and Frozen french fries for sale.

Raw Material---Fresh Potatoes

Finished Product---Potato Chips

Which Market Did The Loyal Potato Chips Plant For Sale In 2021?

Transaction Case Of The Commercial Potato Chips Processing Line With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Commercial Potato Chips Fryer Making Frying Snack Food Machine Manufacturers Food Production Line For Sale Austrian Agent |

2 | 100-150kg/h Capacity Potato Chips Crisps Snacks Chips Food Machine For Sale To Moldova Factory Plant |

3 | 100-150kg/h Frozen French Fries Frying Making Machine Processing Equipment For Sale Ukraine |

4 | 500kg/h Frying Snacks Processing Machine Crispy Potato Chips Processing Machine For Sale Singapore Factory Plant |

5 | 400kg/h Automatic Frozen French Fries Making Machine Potato Chips Production Line For Sale Puerto Rico |

High Quality Trader Customer Case Of The Industrial Potato French Fries Machine Price In 2021 | |

1 | 100kg/h Industrial Potato Chips French Fries Food Maker Machine Production Line For Sale Bolivia Agent |

2 | 800kg/H Industrial Fried Potato Snacks Chips Food Processing Equipment Cost Price For Sale Dominica |

3 | 300kg/h Potato Sticks Food Maker Machine Production Line In Senegal Manufacturers |

4 | 100-150Kg/H Industrial Potato Chip Making Machine Price In Nigeria |

5 | 200-250kg/h French Fries Production Line Factory For Sale Cote d'Ivoire |

6 | 500kg/h Snack Frozen French Fries Production Line Fresh Potato Chips Fryer Making Frying Food Processing Machine Cost For Sale Cameroon |

7 | Professional Manufacturer Potato Chips Making Equipment French Fries Machine For Sale South Africa Food Suppliers |

Customer Case Of The Potato Chips French Fries Production Line With The Farm Setting In 2021 | |

1 | 200-250kg/h Fresh French Fries Flakes Stick Fully Automatic Sweet Potato Chips Machine For Sale Thailand Agent |

2 | 100kg/h Semi-Automatic Potato Chips Production Line Frozen French Fries Making Machine For Sale (Tashkent) Agent |

3 | 500kg/H Fully Automatic Large Potato Chips Machine For Sale America Manufacturers |

4 | 1000kg/H Automatic Potato Chips French Fries Production Line For Brazil Suppliers |

Customer Case Of Muti-Function Fried Potato Chips Making Machine With Discount Price In 2021 | |

1 | 100-150/H Automatic French Fries Maker Potato Chips Processing Making Machine For Sale Senegal Factory |

2 | 150kg Potato French Fries Making Machine Weave Potato Chips Production Line For Sale Nigeria |

3 | 500Kg/H Electric Automatic French Fries Processing Line For Sale Burkina Faso Manufacturing Processing |

4 | 150Kg/H Gas Automatic Potato Chips Sticks Processing Making Machine For Sale Botswana Agent |

5 | 100-150kg/h Industrial Potato Finger Snack Food Making Machine For Sale Philippines Customer Factory Plant |

6 | 800kg/h Potato Chips French Fries Making Production Line Machine For Sale Pakistan With Discount Price For Sale |

7 | 1000 Kg/H Automatic Fried French Fries Production Line For Sale Mozambique |

RFQ Of Potato Chips Manufacturing Plant

1.How Do You Set Up a Chip Factory?

How To Set Up A Potato Chip Making Manufacturing Factory Plant | ||

| 1 | Analyzing The Market Potential Of Potato Chips Production Line | It is very important to analyze the market potential of any business before starting automatic potato chips processing plant. The demand of potato chips is very high in Asian countries. The flavors of these chips are so yummy that hardly anyone can resist them. The demand for potato chips production line price is increasing rapidly. |

| 2 | Investment And Planning Project Of Chips Plant Machinery Cost | Potato chips are a small to medium range of the business model. You can start potato chips plant for sale at home with minimum investment. Firstly, it’s very important to have a plan beforehand. A well-written plan can help you boost your business in a different way. You should think about the investment arrangements of chips plant machinery cost . Also, I advise you to create a plan for marketing strategy. |

| 3 | Find Potato Chips Machinery | Starting potato chips manufacturing plant business requires several types of used potato chips plant for sale to work efficiently. Also, you will need about 300-400 square fit room to establish your machinery. The potato chips machinery cost depends on the demand for the project so choose machines wisely. |

2. How Many Potatoes Is 1 Kg Chips?

Normally, automatic potato chips processing plant takes about 3.5 Kg Potatoes to get final 1 Kg potato chips depending upon the solid content of potatoes as there are diff. varieties being used for the same. In traditional fried chips 30–35% is oil content & 2–10% may be flavor out of 100 gm.

3. Why Are Chips So Expensive?

Overhead costs of oil, gas, labor, rent, water, transport, finance, equipment, electricity and others. After all chips plant machinery cost there had to be enough profit to actually make it worth, automatic potato chips processing plant for store owner to bother making potato chips to support himself and family in a city and do savings and investment besides.

Automatic Potato Chips Processing Plant