800-1000kg/h Output High Productivity Instant Rice Production Line with Siemens ABB

As a professional Instant Rice Production Line, our artificial rice production line can use rice, black rice, buckwheat and other grains (broken rice and rice bran can be reused) as raw materials to produce high-quality enriched artificial rice. Artificial rice is a new food based on extrusion technology. For the rice production line, we dopte rice flour as main raw material, artificial rice is made by extrusion and drying processes. Artificial rice has the advantages of great taste, easy-to-cook, eutrophy, strong functionality (such as sugar-free rice, medicinal rice) etc. Right now, more and more consumers and units received artificial rice. This nutritional rice food machine adopts rice, black rice, buckwheat and other grains(broken rice and rice bran can be reused). You can add additional nutrient components, such as vitamins, minerals etc. After extruding, forming and drying, you can get the nutritional artificial rice, which is eaten same as natural rice.

800-1000kg/h Output High Productivity Instant Rice Production Line with Siemens ABB Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T,Western Union,MoneyGram |

| Supply Ability | 20days / Rice Production Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE,ISO9001,SGS,BV |

800-1000kg/h Output High Productivity Instant Rice Production Line with Siemens ABB Detail Introduction :

BRIF INTRODUCE OF 800-1000KGH OUTPUT HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE WITH SIEMENS ABB

As a professional food product processing machine factory, our artificial rice production line made of stainless steel. And the raw material of the rice can use rice flour, black rice, buckwheat and other grains (broken rice and rice bran can be reused) as raw materials to produce high-quality enriched artificial rice.

SPECIFICATIONS OF 800-1000KGH OUTPUT HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE WITH SIEMENS ABB

| SPECIFICATIONS OF 800-1000KGH OUTPUT HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE WITH SIEMENS ABB | |

| Price | The price is determined by the output and heating method, tell us the configuration you need, we will quote for you soonest |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Output | 100kg/h,200kg/h,300kg/h,500kg/h,1000kg/h,etc. |

| Heating Method | Gas, electrical,diesel |

| Payment Terms | L/C,T/T,Western Union,MoneyGram |

| Supply Ability | 20days for fortified rice production line |

| Delivery Detail | 20days--35days after received the depoist |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE,ISO9001,SGS,BV |

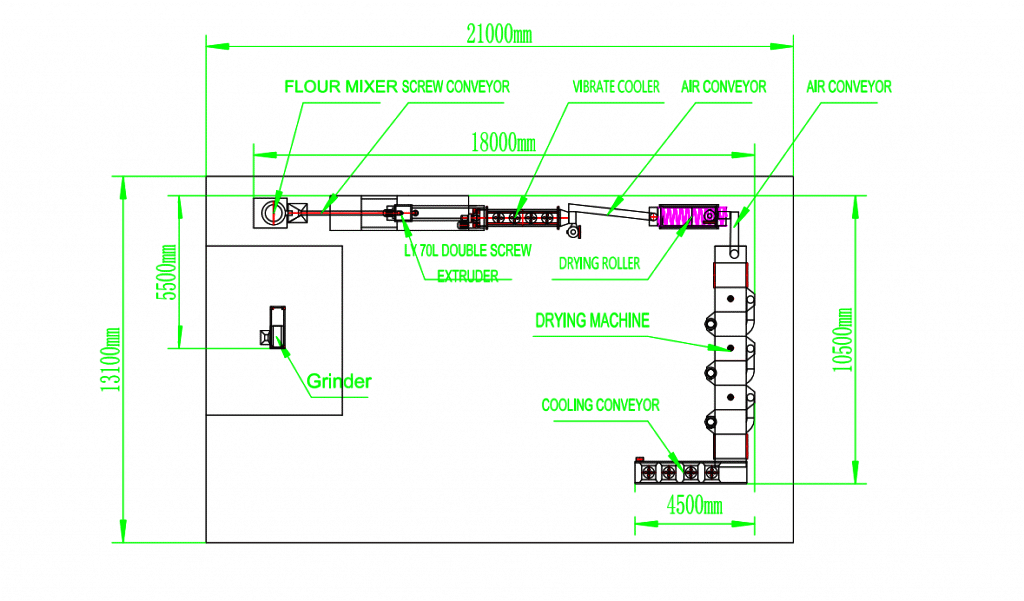

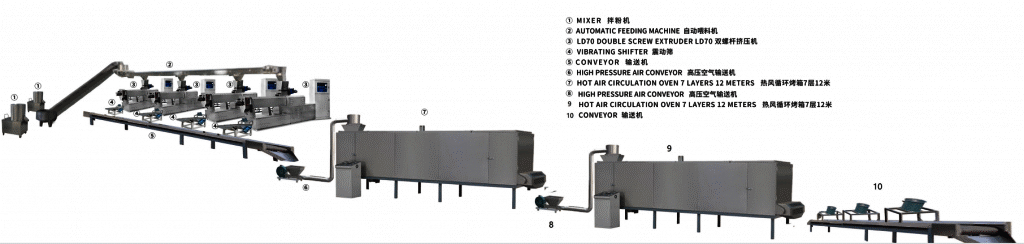

THE FLOW CHART OF NUTRITIONAL RICE MACHINE?

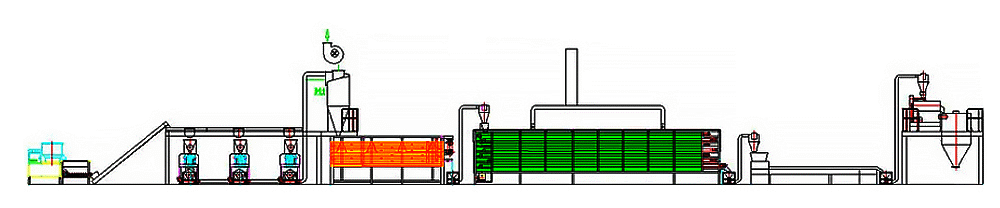

THE COMPLETE PROCESS OF NORMAL CAPACITY(200KG/H) OF RICE PRODUCTION LINE:

MIXER--SCREW CONVEYOR--EXTRUDDER WITH COOLING SYSTEM--VIBRATE COOLER--AIR CONVEYOR--DRYING ROLLER--AIR CONVEYOR--DRYING MACHINE--COOLING CONVEYOR

PS: For the follow chart, we can customized it according to customers’ factory suitation. Such as U shape, stright ship, L shape, etc... Send me your factory size and drawing.

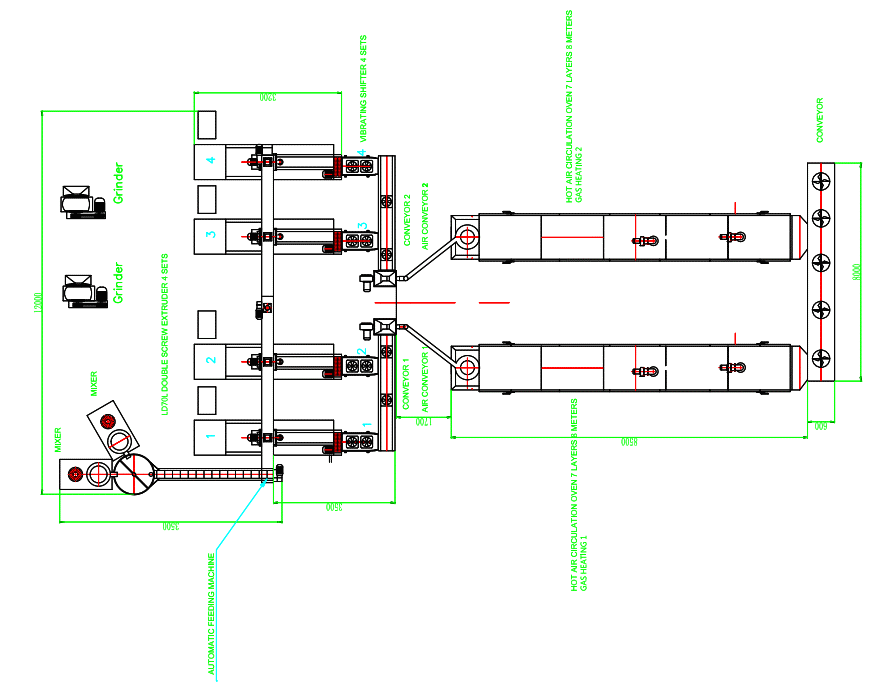

THE COMPLETE PROCESS OF THE BIG 800--1000 CAPACITY OF RICE PRODUCTION LINE:

GRINDER--MIXER--AUTOMATIC FEEDING MACHINE--DOUBLE SCREW EXTRUDER WITH COOLING SYSTEM--VIBRATING SHIFTER--CONVEYOR--HIGH PRESSURE AIR CONVEYOR--HOT AIR CIRCULATION OVEN --HIGH PRESSURE AIR CONVEYOR--HOT AIR CIRCULATION OVEN --COOLING CONVEYOR

TECHNICAL PARAMETER OF NUTRITIONAL RICE MACHINE PRODUCTION LINE

| TECHNICAL PARAMETER OF NUTRITIONAL RICE MACHINE PRODUCTION LINE | ||

| Model | Power Consumption | Output |

| LY65 | 30kw | 100-150g/h |

| LY70L | 37kw | 200-250kg/h |

| LY75 | 75kw | 300-500kg/h |

| LY85 | 85kw | 500-800kg/h |

| LY95 | 105kw | 800-1000kg/h |

PRODUCTS DESCRIPTION OF 800-1000KGH OUTPUT HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE WITH SIEMENS ABB

Artificial rice is a new food based on extrusion technology. For the rice production line, we dopte rice flour as main raw material, artificial rice is made by extrusion and drying processes. Artificial rice has the advantages of great taste, easy-to-cook, eutrophy, strong functionality (such as sugar-free rice, medicinal rice) etc. Right now, more and more consumers and units received artificial rice. This nutritional rice food machine adopts rice, black rice, buckwheat and other grains(broken rice and rice bran can be reused). You can add additional nutrient components, such as vitamins, minerals etc. After extruding, forming and drying, you can get the nutritional artificial rice, which is eaten same as natural rice

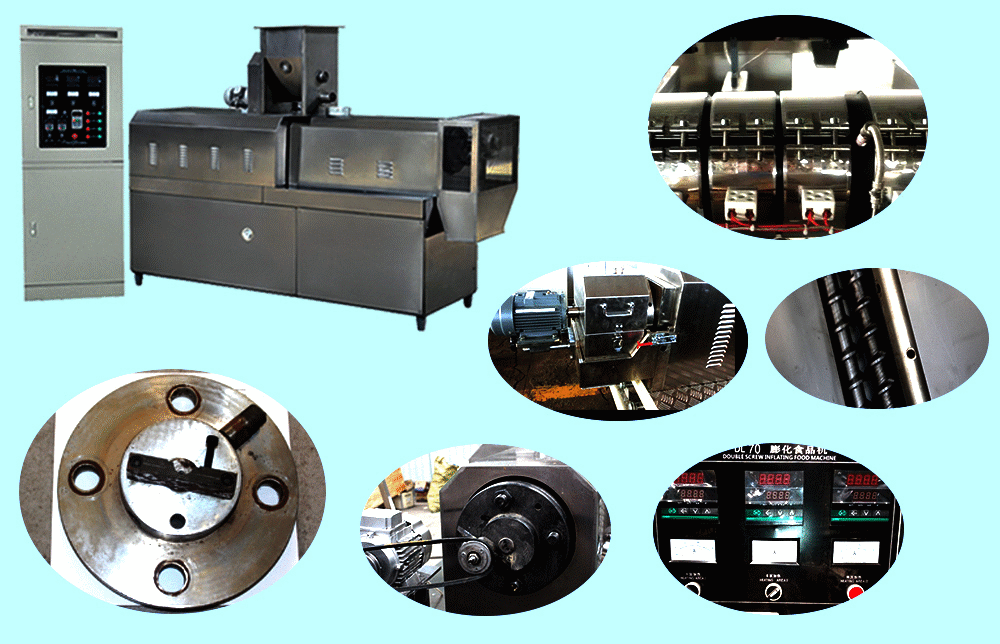

SAMPLE PHOTOS OF 800-1000KGH OUTPUT HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE WITH SIEMENS ABB

This Artificial Rice Making Machine Line can produce many kind shapes and differenct color artificial rice by changing the mould and formula.

MORE DETAILS ABOUT 800-1000KGH OUTPUT HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE WITH SIEMENS ABB

1. Capacity: 100kg/h, 200kg/h, 300kg/h, 500kg/h, 1000kg/h

2. Consumption: Low electricity and labor consumption

3. Design: With flexible design based on the client's demands, we provide turn key project.

4. Grade: SUS304

FUNCTION OF EACH MACHINE OF INSTANT RICE PRODUCTION LINE

1. Flour mixing machine: separate rice noodles or mix with some additives, add a certain amount of water and mix well.

2. Feeding machine: the motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Extruder: There is a special control cabinet, which can extrude rice particles under high pressure environment, adjust the process and change the mold to produce rice grains of different shapes.

4. Vibrating screen: The extruded particles contain a little temperature and viscosity, and the particles are spread out through the vibrating screen to avoid sticking together.

5. Air conveyor: transport products to the oven, and the height of the hoist is determined according to the oven.

6. Multi-layer oven: the oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed, minus the particle moisture, and increase the shelf life.

7. Cooling conveyor: The dried particles contain a certain temperature, and the packaging quality can be guaranteed by cooling to room temperature.

We also equip a automatic feeding system for the instant rice production line. Here are the functions for your reference:

(1)This auto feeding machine feeds many extruder feeders.

(2)The discharge hole adopts a pneumatic valve to match the sensor probe, and it opens and closes automatically.

(3)Automatic feeding system always have raw materials, and a red sensor probe inside.

The probe can automatically detect how much raw material is in the feeder of extruder. When the raw material in the feeder is insufficient, the red probe will sense it, and then feed valve automatically open and unload.

Customer Purchase Case Of Full Automatic Instant Rice Processing Line

| Customer cases for Industrial Instant Rice Making Machine Fortified Rice Processing Line for factory in 2021 | |

| 1 | 200kg/h cost of Industrial Instant Rice Making Machine sold in russia |

| 2 | 1t/h Industrial Instant Rice Making Machine for sale in puerto rico agent |

| 3 | 500kg/h Industrial Instant Rice Making Machine for sale in bolivia |

| 4 | Senegal 1t/h Industrial Instant Rice Making Machine |

| 5 | 1t/h Fortified Rice Processing Line for sale in côte d'ivoire |

| 6 | China 300t/year Industrial Instant Rice Making Machine Fortified Rice Processing Line |

| Customer case of Fortified Rice equipment at 2021 | |

| 7 | 1t/h Fortified Rice equipment for factory in uzbekistan |

| 8 | 1000kg/h Industrial Instant Rice Making Machine for sale in senegal |

| 9 | Mozambique 1t/h Industrial Instant Rice Making Machine |

| 10 | Bangladesh 2t/h Industrial Instant Rice Making Machine |

| Dealed customer have technology of Industrial Instant Rice Making Machine at 2021 | |

| 11 | 1t/h thai Full Automatic Instant Rice Processing Line for factory |

| 12 | Uzbekistan 1t/h Full Automatic Instant Rice Processing Line |

| 13 | Usa 1t/h Full Automatic Instant Rice Processing Line |

| 14 | 800kg/h Full Automatic Instant Rice Processing Line for sale in nigeria |

HIGH PRODUCTIVITY INSTANT RICE PRODUCTION LINE video