Electric Diesel Porridge Maker Machine Instant Rice Making Machine

As a professional instant rice making machine manufacturer, nutritional rice processing line takes rice flour,wheat flour and all kinds of grains powder as raw material. At the same time, it can add some vitamins, trace elements and high nutritional component. Then after mixed evenly, extruded, dried, its shape ,appearance, taste, edible method is the consistent with the natural rice. And also It can be customized with different nutrients and have some special features rice according to different populations. And also, different shapes and appearances of final products can be made by changing different modules in extruder.High automation and accurate control system to save labor cost and also improve the quality of final products. Auto-temperature control system also can makes the temperature control more direct viewing and the parameter more precise

Electric Diesel Porridge Maker Machine Instant Rice Making Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Electric Diesel Porridge Maker Machine Instant Rice Making Machine Detail Introduction :

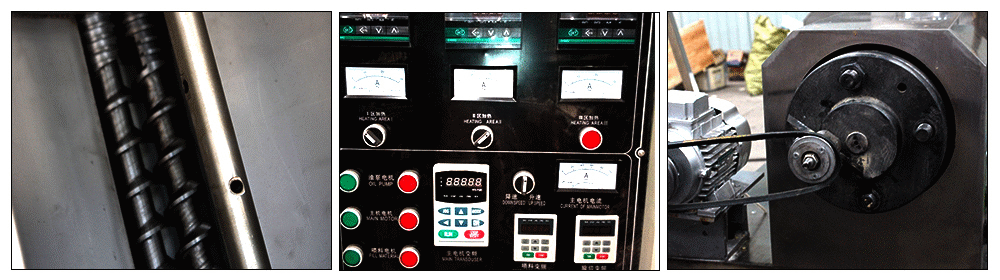

Instant rice making machine has feeding system, extrusion system, rotary cutting system, heating system, transmission system, and also the control system. And Also it uses advanced screw extrusion technology, materials are matured and expanded by high temperature and high pressure, which can be completed in one time.

At the same time, main engine adopts frequency control to ensure the stability of the artificial rice production process. Then the products are of many colors, beautiful look, natural lifelike, nice texture and widely used raw materials. Also, this electric diesel porridge maker machine instant rice making machine production equipment can change different kinds of molds to produce various shapes of nutritional rice products. So in the production process, various microelements can be added according to the formula to enrich the product variety.

Brief introduction of the Full automatic Instant Rice Making Machine Fortified Rice Making Machine

1. Raw materials: Rice flour,corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient. And also it can add some other vitamin and mineral as part of ingredient.

2. Products: Fully Automatic Industrial Extruded Nutritional Rice Machine

3. Capacity: 120-150kg/h, 200-250kg/h, 300-400kg/h, 800-1000kg/h, etc

4. Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz (China standard). At the same time, we can make it according to customers' Local voltage according to different countries (440v/ 415v /480v).

5. Machines materials: so all the machines are made by 304 stainless

6. Products: This line can be produce reinforced rice, golden rice, buckwheat rice and so on.

Technical Parameter Of Full Automatic Fortified Rice Nutrition Rice Making Machine

| Technical Parameter Of Full Automatic Fortified Rice Nutrition Rice Making Machine | ||||

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

| LY65 | 84kw | 59kw | 80-100g/h | 14000x1200x2200mm |

| LY70 | 120kw | 84kw | 120-150kg/h | 16000x1500x2200mm |

| LY75 | 180kw | 135kw | 300-500kg/h | 18000*3500*4300mm |

| LY85 | 225kw | 158kw | 800-1200kg/h | 20000x3500x4300mm |

What Are The Advantages Of The Automatic Fortified Rice Making Machine Instant Rice Making Machine Processing?

1. Various models to meet different output capacity requirements.

2. At the same time, flexible configurations to meet different produce, budget and workshop layout requirement.

3. Vast raw material range to produce different final products by only one production line. All cereal flour are ok, like maize, rice, wheat, millet and so on.

4. And also, different shapes and appearances of final products can be made by changing different modules in extruder.

5. High automation and accurate control system to save labor cost and also improve the quality of final products.

6. Self-cleaning, when stopping, it can be cleaned without disassembling the screws.

7. Auto-temperature control system also can makes the temperature control more direct viewing and the parameter more precise.

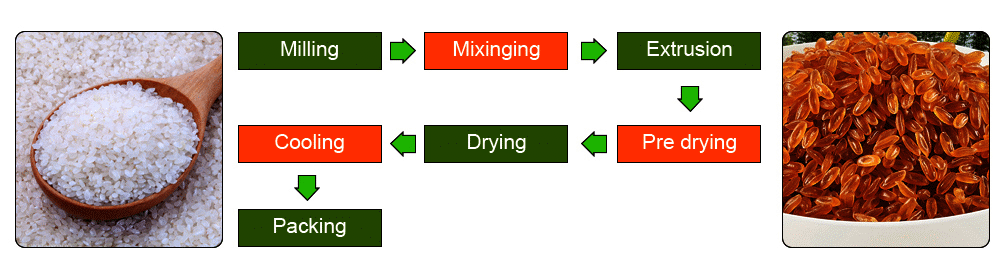

Flow Chart Of Artificial Rice Foods Extrusion Making Machine

Mixer→Screw Conveyor→ Extruder→ Vibration Sieve →Air Conveyor → Dryer →Cooling Machine →Packing Machine

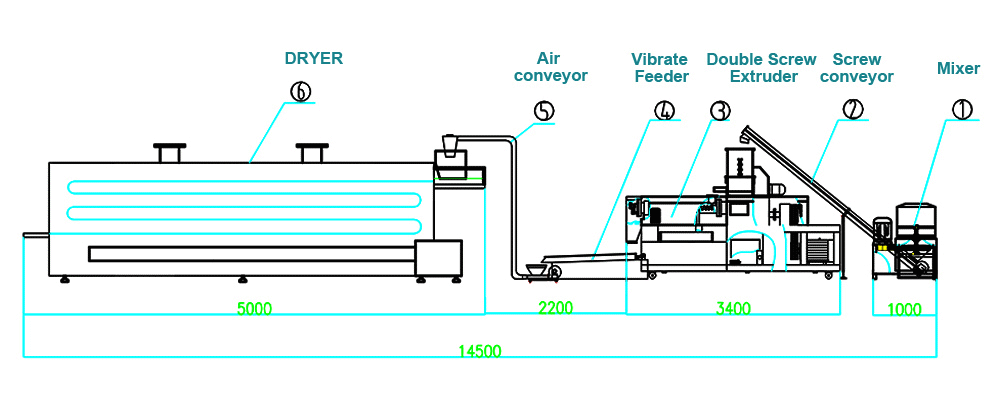

What Kind Of Equipment Using In This Full Automatic Instant Rice Processing Line?

| Flow Chart Of Artificial Rice Foods Extrusion Making Machine | ||

| 1 | Flour Mixer | Mixer makes the raw material adding to water and other chemical additive fully mixed. |

| 2 | Screw Conveyor | Used for material transportation |

| 3 | Double Screw Extruder | Double-screw extruder not only consist of feeding system, extruding system, cutting system, heating system, but lubricating system and controlling system. Also also, extruder is the main Machine For forming and shaping. |

| 4 | Vibrate Cooler | Used to spread the product to the next device averagely. |

| 5 | Air Conveyor | Conveying rice to drying oven |

| 6 | Drying Machine | To Dry the rice. And also this kind of oven has a wide range of application. At the same time, It can dry all shapes of puffing food, including strip, lump, granular materials and so on. As well as other types of materials. Also users can choose different types with different layer, length, and heating mode. |

| 7 | Cooling Conveyor | The rice coming out of the oven is cooled by natural wind. |

Sample Pictures:

What is the Main Feature of the Industrial Instant Rice Making Machine Fortified Rice Processing Line ?

| Main Feature of the Industrial Instant Rice Making Machine Fortified Rice Processing Line | |

| 1 | This part that contacts mixer to material uses the stainless steel material. And also the discharge hole adopts the new handle-opened design, good seal. |

| 2 | At the same time, the main extruder adopts frequency speed controlling with high automation and stable per-formation. |

| 3 | The screws are made of the alloy steel and special craft, durable usage, high pressure, and also the screw life is longer. And then Using the building block structure and combining willingly according to the different demand. |

| 4 | The forced lubrication system can guarantee the equipment transmission life longer. |

| 5 | The auto-temperature control system makes the temperature control more direct viewing, and then the parameter more precise. |

| 6 | Self-cleaning. So when stopping, it can be cleaned without disassembling. |

| 7 | This equipment has the wide material, multi-shape products, and flexible collocations. So it can produce different products according to the different models and collocations. |

| 8 | Barrel with water-cooled circulation, so raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Ans also it with different moisture-extrusion temperature ratio, whole-expanded, and then the half expanded as different type of products. |

| 9 | The dryer not only has a compact structure, small occupying, large drying area, but small surface area, slight radiating heat, and high thermal efficiency. |

Customer Purchase Case Of Full Automatic Instant Rice Processing Line

| Customer cases for Industrial Instant Rice Making Machine Fortified Rice Processing Line for factory in 2021 | |

| 1 | 200kg/h cost of Industrial Instant Rice Making Machine sold in russia |

| 2 | 1t/h Industrial Instant Rice Making Machine for sale in puerto rico |

| 3 | 500kg/h Industrial Instant Rice Making Machine for sale in bolivia |

| 4 | Senegal 1t/h Industrial Instant Rice Making Machine |

| 5 | 1t/h Fortified Rice Processing Line for sale in côte d'ivoire |

| 6 | China 300t/year Industrial Instant Rice Making Machine Fortified Rice Processing Line |

| Customer case of Fortified Rice equipment at 2021 | |

| 7 | 1t/h Fortified Rice equipment for factory in uzbekistan |

| 8 | 1000kg/h Industrial Instant Rice Making Machine for sale in senegal |

| 9 | Mozambique 1t/h Industrial Instant Rice Making Machine |

| 10 | Bangladesh 2t/h Industrial Instant Rice Making Machine |

| Dealed customer have technology of Industrial Instant Rice Making Machine at 2021 | |

| 11 | 1t/h thai Full Automatic Instant Rice Processing Line for factory |

| 12 | Uzbekistan 1t/h Full Automatic Instant Rice Processing Line |

| 13 | Usa 1t/h Full Automatic Instant Rice Processing Line |

| 14 | 800kg/h Full Automatic Instant Rice Processing Line for sale in nigeria |

Full Automatic Instant Rice Processing Line video