Non-Fried Instant Noodles Production Line High Automation 60000pcs/ 8hours

As a professional manufacturer of instant noodle making machine, we have been in the field of Corn Puff Extruder Machine for 18 years. We are the supplier of instant noodle making machine, our instant noodle making machine design good manufacturing process. Instant noodle processing line is new type of noodles processing machine, first you need to mix the wheat flour or other grain flour with water by flour mixer, then put the mixed dough into the noodle machine, and the machine will press the wheat dough into flat shape by several noodles rollers, then the flat will be cutted into noodles shape by the knife behind the rollers.can make many different type noodles such as fresh noodle,dry noodle ,vegetable noodle,grain noodle.Chinese noodle etc, as the industrial noodle making machine price is very attractive, it can be widely used at noodles manufacturing plant.

Non-Fried Instant Noodles Production Line High Automation 60000pcs/ 8hours Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Non-Fried Instant Noodles Production Line High Automation 60000pcs/ 8hours Detail Introduction :

Non-Fried Instant Noodles Production Line High Automation 60000pcs/ 8hours can take corn, rice, wheat, oat, grains, potato flour, and others as raw materials, to make the instant noodles, and then sell them to various restaurants, restaurants, fast food stores.

60000pcs/8hours Production Instant Noodle Making Processing Machine Production Line is suitable for fired instnant noodle production from maxing to packing.

It is simple operation, modereate output, energy saving and high cfficiency, small floor space, low investment and quick effect. It is especially suitable for small and medium enterprises.

TECHNICAL PARAMETERS FOR Non-Fried Instant Noodles Production Line High Automation 60000pcs/ 8hours

| TECHNICAL PARAMETERS FOR Non-Fried Instant Noodles Production Line | |

| Capacity: | 60000pcs/8hours |

| Converter: | customizable |

| Function: | Multifunction |

| Installation: | Engineer Guide |

| Voltage: | customizable |

| Heating source for continuous dryer: | Electric/Gas/Steam |

| Key Words: | instant noodle machine;instant noodle making machine |

WORKING PROCESS OF Non-Fried Instant Noodles Production Line

1.This automatic instant noodles plant can also be used to produce non-fried instant noodle by changing the frying machine,which can also produce cup instant noodles by changing mould.

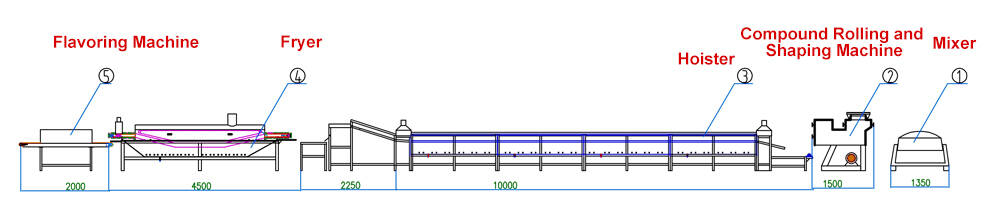

The Production flow chart:

wheat flour, dressing mixer →curing machine →Composite continuous rolling→steamed noodles → frame cutting→folding → deep fry → cooling → packing.

We can also provide special designing production line according to clients' special requirements.

Free formula, local installation, workshop design, machine inspection service are provided, any instant noodle production line mini instant noodles making machine automatic need will be met if inquiries.

2.Structure and principle of multi-functional fried instant noodle production line

Instant noodle production line is composed of brine mixer, brine measuring device, dual-axis mixer, aging machine, compound roller, single layer (multi-layer) steamer, square (and round) noodle cutting and dividing machine, fryer, cooling machine, conveyor

THE SAMPLE OF Non-Fried INSTANT PRODUCTION LINE

FEATURES OF Non-Fried INSTANT PRODUCTION LINE

| FEATURES OF NON-FRIED INSTANT PRODUCTION LINE | |

| 1. | Fried instant noodles production line are alternative. |

| 2. | Producing square, circular instant noodles or both shape by changing parts of configurations. |

| 3. | Producing various specifications of noodle block. |

| 4. | Offer professional technical support, after-sales service, customized solution. |

THE DETAIL FOR 60000PICES/8HOURS INSTANT NOODLES PRODUCTION LINE

DETAILS & FEATURES

| THE DETAILS OF Non-Fried INSTANT PRODUCTION LINE | |

| 1. | The size of instant noodles can be adiusted easily. |

| 2. | pressing & shapping machine,cutting machine and frying machine are all frequency control. |

| 3. | Rolling pressing design make the noodles springy. |

| 4. | Adopt good quality and food-grade stainless steel,which is longer service life and neatness. |

| 5. | Longer frying length to ensure good cooking and better taste of instant noodles. |

| 6. | Cooling conveyor is special designed with oil filtering function. |

| 7. | High automation and accurate control systerm to save labor cost and improve the quality of final products. |

8.Our Service

| Service for Pre-sale | Service for After-sale |

| 1.Provide technical parameter 2.Factory layout and size suggestion 3.Provide general formulation 4.Custom-Design service 5.Professional Advice about Market, machines, materials, packing 6. Suggesting professional ship agent or helping book ship as customer request. 7. 24 hours online service. | 1.Allocation chart as the buyer's request will be supplied. 2.Operation manual will be supplied after shipment. 3.One year w arrantee, life time maintenance with cost price. 4.Free easy broken spare parts will be sent with container . 5.First installation can be done by engineer. 6.Training workers in customer's factory. |

Customer Cases for instant noodles production line in 2021

| 30000pcs/8 H industrial instant noodles production line for sale in Uzbekistan |

| 60000/8h industrial automatic instant noodles production line for sale in Senegal |

| Mozambique 30000PCS/8H Industrial instant noodles manufacturing process |

| Bangladesh 80000pcs/8h Industrial Industrial instant noodles manufacturing process |

| 60000PCS/8H Thai manufacturing instant noodles Production Line |

| 11000PCS/8H Small raw materials for noodles production For Sale Botswana |

| LYFISH-5 raw materials for noodles production for sale Pakistan |

| Small 200kg/h ingredients of instant noodles production line Moldova |

| 60000pcs/8h instant noodle processing line for sale Ukraine |

| 11000pcs/8h small electric instant noodle processing line for sale Singapore |

| 11000pcs/8H instant noodle production line For Sale Puerto Rico |

| 30000pcs/8h instant noodle line machine for sale Bolivia |

| 60000pcs/8h instant noodle line For Sale Dominica |

| 40000pcs/8h instant noodle line in Senegal |

| 100000KG/H noodles production line In Nigeria |

| 11000/8H noodles production line For Sale Cote d'Ivoire |

| 60000pcs/8h noodles production line For Sale South Africa |

| Small electric instant noodle production line for sale Lebanon |

| 60000pcs/8h instant noodle production line for sale UAE |

WHY CHOOSE US?

COMPANY PROFILE OF LOYAL INDUSTRIAL

Shandong Loyal Industrial Co., Ltd. is actually specialist manufacturer of meals equipment, snack foods machines. Experienced developers is helping us whose project is to research brand-new machines, design for clients.

compensation equipment for customers. 1 day's solution as well as 15 after sales solution staffs aid our clients to handle all the errors of our devices immediately.

We are professional manufacturer of food machine. We mainly deal with the manufacture, research and development of the snacks food machinery. According to clients' different demands, we could offer the whole complete processing line for all kinds of expanded snacks, 2D and 3D pellet, potato chips, corn flakes, nutrition powder, pet food and so on. And our technical assistance will help clients produce high quality products all the time.

OUR SERVICE

Service for Pre-sale Service for After-sale

1.Provide technical parameter

2.Factory layout and size suggestion

3.Provide general formulation

4.Custom-Design service

5.Professional Advice about Market, machines, materials, packing

6. Suggesting professional ship agent or helping book ship as customer request.

7. 24 hours online service. 1.Allocation chart as the buyer's request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year w arrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer's factory.

ENGINEERS AVAILABLE TO SERVICE MACHINERY OVERSEAS

1.Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warranty and lifetime maintenance service.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment?

A: 30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment.

Q: Guarantee?

A: Within 12 months.

Q: Contact Information?

A: Any question please contact us! Welcome to Loyal.