Fully Automatic Potato Chips Line

Automatic potato chips making machine is designed for making the potato chips &frozen french fries. Raw materials can be fresh potato, fresh cassava etc. Through the washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips. After flavoring with the flavor powder can get many kinds of taste of delicious chips. We will provide automatic potato chips making machine project formula and technology guidance free of charge to make sure customers can make high quality and delicious potato chips. As One of the largest fried potato chips making machine manufacturer, the loyal fully automatic potato chips line have been exported to the United Kingdom, Singapore, Canada, Brazil, Western Europe and other 116 countries and regions, promoting the development of the local economy.

Fully Automatic Potato Chips Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Model Number | LY100, LY 200, LY 500 |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| MOQ | 1 set/Fully Automatic Potato Chips Line |

| Keywords | Automatic Potato Chips Line |

| Raw material | Fresh potato,cassava |

| Automatic | Automatic potato chips making machine project |

| Certification | CE,ISO9001,SGS,BV |

| Material | Stainless Steel 304 |

| Warranty | 1 Year |

Fully Automatic Potato Chips Line Detail Introduction :

Automatic potato chips making machine is designed for making the potato chips &frozen french fries.Raw materials can be fresh potato, fresh cassava etc. Through the washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips. After flavoring with the flavor powder can get many kinds taste of delicious chips. The crispy taste with different flavors and packaging, suitable for all ages. We will provide automatic potato chips making machine project formula and technology guidance free of charge to make sure customers can make high quality and delicious potato chips.

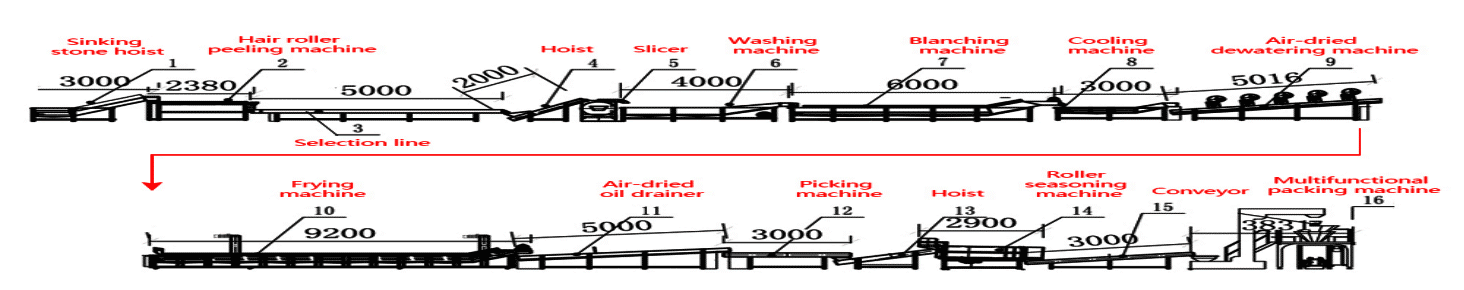

What Kind Of Machine Used In The Processing Of Fully Automatic Potato Chips Line?

Equipment List Process Flow Of Fresh Potato Chips Production Line | |

| Hoist | Automatic Lifting And Feeding, Convenient, Efficient And Fast, Saving Manpower |

| Cleaning And Peeling Machine | Automatic Potato Cleaning And Peeling, High Efficiency And Energy Saving |

| Picking Line | Remove The Bad Pits Of The Soil Tofu And Improve The Quality |

| Slitting Machine | Efficient Slitting, Adjustable Size |

| Conveyor | Lift The Potato Chips To The Blanching Machine |

| Blanching Machine | Remove The Starch On The Surface Of Potato Chips, Inhibit The Activity Of Active Enzymes, And Protect The Color |

| Vibrating Drainer | Remove The Scraps That Are Too Small, And Vibrate To Remove Excess Water |

| Air Cooling Line Removes Water | Air Cooling Removes The Water On The Surface Of The Potato Chips And Transports Them To The Fryer |

| Fryer | Fry To Color And Optimize Texture And Taste |

| Vibrating Oil Drainer | Vibrating To Remove Excess Oil |

| Air Cooling Line | To Remove Oil And Cool Down - Blow Off The Excess Oil On The Surface, And Fully Cool The Potato Chips So That They Can Enter The Quick Freezer |

| Quick Freezer | Quick-Potato Chips Frozen Are Convenient For Storage And Transportation After Packaging, And Optimize The Taste |

HOW MUCH DOES IT COST TO MAKE POTATO CHIPS?

Price Cost Of Potato Chips Production Line | |||||

Type | Heating Model | Dimension | Output | Degree Of Automation | Price(USD) |

LY100 | Gas/Electrical | 25000*1500*2100mm | 100kg/h | Automatic | 50,000-70,000 |

LY200 | Gas/Electrical | 27000*1500*2100mm | 200kg/h | Automatic | 60,000-80,000 |

LY300 | Gas/Electrical | 28000*1500*2100mm | 300kg/h | Automatic | 70,000-10,0000 |

LY400 | Gas/Electrical | 29000*1500*2100mm | 400kg/h | Automatic | 70,000-100,000 |

LY500 | Gas/Electrical | 29000*1500*2100mm | 400kg/h | Automatic | 70,000-100,000 |

FULL AUTOMATIC POTATO CHIPS LINE COMMUNAL CONDITION INDEX

Index Of Fresh Potato Chips Production Line | |

Steam:0.3/h | Pressure: 0.8Mpa |

Heating Power:300 000 Kcal | Water Consumption: 5.0t/h, Drinking Water. |

Pressing Air(0.8Mpa):0.5m³/h | Workshop Acreage: 300m2 (Exclude Frozen Warehouse) 15 Worker Including Engineer |

Power: Equipment Powder 35kw,220/380V5%,50Hz1%( Does Not Includes Frozen Warehouse, Boiler, And Lighting System) | |

ABB Motor Of Full Automatic Potato Chips Making Processing Line | ||

| 1 | Package Level 1 Units | 0 carton |

| 2 | Product Name | 3-Phase squirrel cage motor |

| 3 | Product Net Weight of Automatic Potato Chips Making Plant | 5.9 kg |

| 4 | Product Type | 3AA2__M3AA_IE2_AA |

| 5 | SCIP of Potato Chips Processing Plant | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

| 6 | Selling Unit of Measure | piece |

| 7 | Standards of Potato Chips Automatic Plant Cost | IEC 60034-1 |

| 8 | Starting of Motor | Direct Online |

IS POTATO CHIPS MAKING BUSINESS PROFITABLE?

According to relevant data released by the State Council, the annual output value of the domestic snack industry has reached 2,215.6 billion yuan. It is expected that this year, the total output value of the domestic snack industry will reach 3 trillion yuan. In the past two years, people have pursued freshness and individuality in food consumption, but no matter how the Internet celebrity models are replaced, snacks havealways occupied the top consumption list of residents. "Food goods" has become more and more a label, hanging on many young people. The post-90s and post-00s are the main force of snack consumption, and their increasing consumption level has also continuously stimulated the vitality of the leisure snack industry. As a traditional snack food, potato chips have a development history of more than 160 years, but they are still enduring in the snack market and occupy half of the industry. Industry insiders said that in recent years, the potato chip industry has continued to integrate capital, and accelerated the laying of sales channels. The penetration rate of domestic potato chips has reached nearly 80%.

HOW ABOUT THE LOYAL COOPERATED CUSTOMERS OF FULL AUTOMATIC POTATO CHIPS LINE ?

LOYAL's share of potato chips line exported to international markets has steadily increased. According to the export goods trade data in 2021, Loyal's export market share in the international market is 86.5%, of which the potato chips line market share is 20.8%, the export market share in the Americas is 30.2%, and the export market share in Asia is 35.5%. If you are interested in a full automatic potato chips line, please contact us today, we offer you the most cost-effective turnkey solution.

Customer Cases For Automatic Continuous Deep Fryer Machine In 2021

High Quality Trader Customer Case Of The Industrial Potato French Fries Machine Price In 2021 | |

1 | 100kg/h Industrial Potato Chips French Fries Food Maker Machine Production Line For Sale Bolivia Agent |

2 | 800kg/H Industrial Fried Potato Snacks Chips Food Processing Equipment Cost Price For Sale Dominica |

3 | 300kg/h Potato Sticks Food Maker Machine Production Line In Senegal Manufacturers |

4 | 100-150Kg/H Industrial Potato Chip Making Machine Price In Nigeria |

5 | 200-250kg/h French Fries Production Line Factory For Sale Cote d'Ivoire |

6 | 500kg/h Snack Frozen French Fries Production Line Fresh Potato Chips Fryer Making Frying Food Processing Machine Cost For Sale Cameroon |

7 | Professional Manufacturer Potato Chips Making Equipment French Fries Machine For Sale South Africa Food Suppliers |

Customer Case Of The Potato Chips French Fries Production Line With The Farm Setting In 2021 | |

1 | 200-250kg/h Fresh French Fries Flakes Stick Fully Automatic Sweet Potato Chips Machine For Sale Thailand Agent |

2 | 100kg/h Semi-Automatic Potato Chips Production Line Frozen French Fries Making Machine For Sale (Tashkent) Agent |

3 | 500kg/H Fully Automatic Large Potato Chips Machine For Sale America Manufacturers |

4 | 1000kg/H Automatic Potato Chips French Fries Production Line For Brazil Suppliers |

Transaction Case Of The Commercial Potato Chips Processing Line With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Commercial Potato Chips Fryer Making Frying Snack Food Machine Manufacturers Food Production Line For Sale Austrian Agent |

2 | 100-150kg/h Capacity Potato Chips Crisps Snacks Chips Food Machine For Sale To Moldova Factory Plant |

3 | 100-150kg/h Frozen French Fries Frying Making Machine Processing Equipment For Sale Ukraine |

4 | 500kg/h Frying Snacks Processing Machine Crispy Potato Chips Processing Machine For Sale Singapore Factory Plant |

5 | 400kg/h Automatic Frozen French Fries Making Machine Potato Chips Production Line For Sale Puerto Rico |

Customer Case Of Muti-Function Fried Potato Chips Making Machine With Discount Price In 2021 | |

1 | 100-150/H Automatic French Fries Maker Potato Chips Processing Making Machine For Sale Senegal Factory |

2 | 150kg Potato French Fries Making Machine Weave Potato Chips Production Line For Sale Nigeria |

3 | 500Kg/H Electric Automatic French Fries Processing Line For Sale Burkina Faso Manufacturing Processing |

4 | 150Kg/H Gas Automatic Potato Chips Sticks Processing Making Machine For Sale Botswana Agent |

5 | 100-150kg/h Industrial Potato Finger Snack Food Making Machine For Sale Philippines Customer Factory Plant |

6 | 800kg/h Potato Chips French Fries Making Production Line Machine For Sale Pakistan With Discount Price For Sale |

7 | 1000 Kg/H Automatic Fried French Fries Production Line For Sale Mozambique |