Continuous Stainless Steel Potato Chips Industrial Fryer Machine

The continuous stainless steel potato chips industrial fryer machine are specially designed to save water, oil and energy during the frying process. The fully automatic industrial continuous frying machines are used to fry a variety of foods such as potato chips, french fries, peanuts, onions, chicken and more. Therefore, industrial frying machine is the first choice for manufacturers of vegetable, fruit , snacks food and other food processing lines. At the same time, loyal also can provide a full set service of automatic continuous frying machine , like cost accounting, commercial potato chips deep fryer design, potato chips recipes, frying machine installation and debugging according to customer requirements and to provide the most effective help for customers' production. At present, the loyal fully automatic conveyor belt deep fryer has been exported to Singapore, Canada, Brazil, Western Europe and other countries and regions, which has promoted the development of the local economy.

Continuous Stainless Steel Potato Chips Industrial Fryer Machine Specifications :

| Model Number | Tainless Steel Potato Chips Industrial Fryer Equipment |

| Place of Origin | China |

| Min.Order Quantity | 1set Of Industrial Fryer Machine |

| Payment Terms | D/P,T/T, |

| Delivery Detail | 20days--35days |

| Packaging Details | Export-compliant Frying Equipment Packaging |

| Team | Fryer Drying Sterilizing Machine Technical Team |

| Sales Team | Professional Fryer Technology Team |

| Honor | A Number Of National Fryer Equipment Patents |

Continuous Stainless Steel Potato Chips Industrial Fryer Machine Detail Introduction :

The continuous stainless steel potato chips industrial fryer machine is made of high quality SUS 304 stainless steel. Fully automatic industrial continuous frying machines can be transported by feeding mesh belt, and conveying speed can be adjusted according to the product type and frying time.This automatic continuous frying machine is important part in automatic potato chips/frozen French fries production line. The continuous frying production line automatic potato chips frying process, saves labor and reduces production costs. Fully automatic conveyor belt potato chips deep fryer is also suitable for frying chicken nuggets, potato chips, chin-chin, French fries, etc.

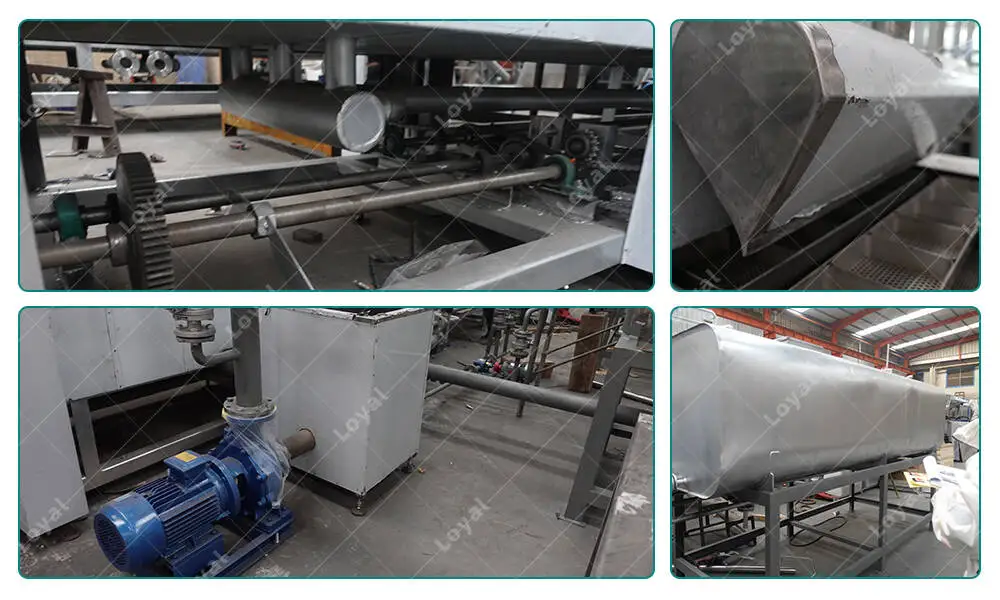

What Is The Structures Of The Continuous Stainless Steel Potato Chips Industrial Fryer Machine?

Continuous stainless steel potato chips industrial fryer machine is fully made of stainless steel material, automatic continuous potato chips frying machine has unique products conveying system, slag discharging system, heating system, oil circulation system, smoke exhaust system, electric control system, etc. Also loyal designed industrial potato chips frying machine can equipped with oil storage tank, optional mesh belt filter, humanization design makes simple operation and reduces manual working, then improve the working efficiency.

Raw Material Handling System: This section is responsible for preparing raw materials, such as washing, cutting, and soaking, to get them ready for frying.

Frying System: This is the core part of the production line, used to fry the prepared materials into snacks. It usually includes fryers, oil temperature control systems, and timers.

Oil Management and Recovery System: To increase efficiency and reduce waste, modern production lines are equipped with oil filtration and recycling systems.

Seasoning and Packaging System: After frying, the products are seasoned and cooled, then packaged. This step ensures the flavor and quality of the products while also facilitating storage and transportation.

The Technical Parameter Of The Continuous Potato Chips Fryer Machine

The Technical Parameter Of The Continuous Stainless Steel Potato Chips Industrial Fryer Machine | ||||||||

Model | Heating | Power (kw) | Temperature | Weight (kg) | Capacity (kg/h) | Mesh Belt (mm) | Oil Volume (L) | Size (mm) |

LY-3500 | Electric | 102.25 | 0-300℃ | 800 | 200 | 800 | 800 | 3700*1400*2300 |

LY-3500 | Gas | 2.25 | 0-300℃ | 1200 | 200 | 800 | 1200 | 3700*1700*2300 |

LY-4000 | Electric | 112.25 | 0-300℃ | 1000 | 300 | 800 | 950 | 4200*1400*2300 |

LY-4000 | Gas | 2.25 | 0-300℃ | 1400 | 300 | 800 | 1420 | 4200*1700*2300 |

LY-5000 | Electric | 123 | 0-300℃ | 1200 | 500 | 800 | 1230 | 5200*1400*2300 |

LY-5000 | Gas | 3 | 0-300℃ | 1600 | 500 | 800 | 1850 | 5200*1700*2300 |

LY-6000 | Electric | 183 | 0-300℃ | 1400 | 800 | 800 | 1520 | 6200*1400*2300 |

LY-6000 | Gas | 3.7 | 0-300℃ | 1800 | 800 | 800 | 2280 | 6200*1700*2300 |

LY-7000 | Electric | 213.7 | 0-300℃ | 1600 | 900 | 800 | 1810 | 7200*1400*2300 |

LY-7000 | Gas | 3.7 | 0-300℃ | 2200 | 900 | 800 | 2700 | 7200*1700*2300 |

What Is The Cost Of The Continuous Stainless Steel Potato Chips Industrial Fryer Machine?

As we all know that the cost of each continuous potato chips deep fryer is different, which leads to different fryer models and configurations. Loyal company can provide customers with relative fryer according to their food making processing line needs and machine best design. The continuous stainless steel potato chips industrial fryer machine price of a single machine is about from USD5,000 to USD30,000. Similarly, Loyal can also provide the whole industrial continuous frying food processing line, which probably costs more than USD100,000, which is possible to equip a filter system according to customer needs.

What Is The Feature Of Continuous Stainless Steel Potato Chips Industrial Fryer Machine?

The Feature Of The Automatic Continuous Frying Machine | |

1 | The continuous stainless steel potato chips industrial fryer machine uses oil-water mixed frying technology to automatically filter residue, which can extend the oil change period and greatly reduce the cost. |

2 | The mesh belt is made of stainless steel, which is corrosion resistant, high temperature resistant, oil resistant and durable. |

3 | Adopt variable frequency step-less speed regulation, so the frying time is adjustable. |

4 | This continuous potato chips fryer is equipped with automatic lifting system, upper cover and mesh belt for lifting, convenient for manual cleaning. |

5 | The device is equipped with high-efficiency thermal conductivity device, ensure high energy utilization efficiency. |

6 | Equipped with a dynamic circulation system to filter oil residue in the production process. |

7 | The upper and lower double-layer mesh belts are used for transmission, and the product is sandwiched between the double-layer mesh belts to prevent fried food from floating. |

8 | Automatic temperature control, with over-temperature protection device to ensure product quality and safe production. |

9 | Adopt the newest and advanced technology: frying machine can saving 50% energy, 40% oil and gas than common fryer. |

What Is The Best Oil For Frying Potato Chips?

Oils that consist mostly of saturated and monounsaturated fats are best for continuous stainless steel potato chips industrial fryer machine because they’re the most stable at high heat.

Healthy oil for cooking will:

A.have a high smoke point.

B.be stable, so they don’t react with oxygen when heated.

C.taste is also important. When deep frying, oils with a neutral flavor are usually preferable.

What kind of vegetable oils can be used in the deep frying work? Palm oil consists mostly of saturated and monounsaturated fats, making it a great choice for deep frying. The flavor can be neutral, particularly if you use the unrefined variety known as red palm oil.

The Applications Of The Continuous Stainless Steel Potato Chips Industrial Fryer Machine

Industrial frying machine fit for the different fried food processing enterprises, can make all kinds of foods. The products are:

1.Broad beans, green beans, peanuts and other nuts;

2.Potato chips and other puffed food;

3.Sesame and other flour products;

4.Meat pieces, chicken legs and other meat products.

Customer Cases For Continuous Stainless Steel Potato Chips Industrial Fryer Machine In 2021

Customer Case Of Full Automatic Continuous Potato Chips Deep Fryer At Discount Prices In 2021 | |

1 | 500kg/h Continuous Stainless Steel Potato Chips Industrial Fryer Machine For Sale Nigeria |

2 | High Quality Automatic Conveyor Belt Continuous Fryer Snack 2D/3D Pellet Frying Machine For Sale Sudan |

3 | Conveyor Continuous Deep Fryer Machine Nuts Fryer Machine For Sale Burkina Faso |

4 | 800kg/h Continuous Fryer Snacks Frying Machine For Sale Botswana |

Customer Case Of The Continuous Mesh Belt Potato Chips Frying Machine In 2021 | |

1 | 500kg/h Electric Continuous Stainless Steel Potato Chips Industrial Fryer Machine For Sale Mozambique |

2 | 800-1000 kg/h Pellet 3D Snacks Machine Continuous Deep Fryer Machine For Sale Australia |

3 | 350kg/h Automatic Chicken/ Beef Continuous Deep Fryer Machines For Sale Moldova |

4 | 250kg/h Full Automatic Nuggets Burger Continuous Deep Fryer Machines For Sale Ukraine |

5 | 1000kg/h Auto Crispy Onion Frye With Continuous Filtration System For Sale Ireland |

Repurchase Case Customer With Continuous Frying Machine Technology In 2021 | |

1 | Continuous Fryer Frying Machine Tortilla Chips Deep Fries Machines For Sale Puerto Rico |

2 | 300kg/h Automatic Banana Chips Continuous Fryer Frying Cooking Machine Sale To Bolivia |

3 | 600kg/h PLC Control Continuous Stainless Steel Potato Chips Industrial Fryer Machine For Sale Dominica |

4 | 1000kg/h Large Capacity Continuous Fryer Cassava Chips Deep Fries Machines For Sale In Senegal |

5 | 300kg/h Snacks 2D Pellet Chips Continuous Belt Deep Frying Equipment Price In Nigeria |

Transaction Case Customer Of Industrial Continuous Deep Fryer Machine In 2021 | |

1 | 1000kg/h Continuous Automatic Gas Chin Chin Belt Frying Oil Fryer Machine For Sale Thailand |

2 | 600kg/h Automatic Continuous Chips Pellet Snack Deep Fryer Machine For Sale Iran |

3 | 500kg/h Chicken Chop Tempura Shrimp Squid Rings Continuous Fryer Frying Machine For Sale Australia |

4 | 1000kg/h Continuous Automatic Nuts Belt Frying Oil Fryer Machine For Sale With New Technology To India |

5 | 600kg/h Automatic Continuous Stainless Steel Potato Chips Industrial Fryer Machine For Sale Zimbabwe |

6 | 800kg/h Continuous Automatic Gas Cassava Chips Belt Fryer Machine For Sale Turkmenistan |