Corn Flakes Making Machine Manufacturing Breakfast Cereal Sweet Corn Flakes Processing Equipment

The fully automatic corn flakes making machine manufacturing breakfast cereal sweet corn flakes processing equipment adopts advanced puffing and extrusion technology. By changing the mold and changing the production process, the operator can more easily and better produce the popular salad snacks on the market to meet the needs of the market. The production line has a small footprint, flexible configuration, easy operation and strong adaptability, and is well received by the industry. At the same time, corn flakes breakfast cereals can not only fortify many trace elements, such as vitamins and minerals, but also add cocoa and sugar, such as honey, maltose, etc. . It can be eaten directly after adding milk, coffee, yogurt or functional drinks. Children can also eat breakfast cereals as sweet and crunchy snacks. According to the taste, there are light corn flakes, sweet corn flakes and salted corn flakes.

Corn Flakes Making Machine Manufacturing Breakfast Cereal Sweet Corn Flakes Processing Equipment Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Corn Flakes Making Machine Manufacturing Breakfast Cereal Sweet Corn Flakes Processing Equipment Detail Introduction :

Corn flakes are a new type of breakfast food with high nutritional value. Corn flakes making machine manufacturing breakfast cereal sweet corn flakes processing equipment is mainly made of grains as the basic raw material and is processed by cooking or extrusion. The shapes are granular, flake, or animal-shaped. The outstanding feature of the nutritious breakfast cereal corn flakes production line is that it is rich in complex carbohydrates and dietary fiber.

At the same time, corn flakes breakfast cereals can not only fortify many trace elements, such as vitamins and minerals, but also add cocoa and sugar, such as honey, maltose, etc. Corn flakes making machine manufacturing breakfast cereal sweet corn flakes processing equipment can be eaten directly after adding milk, coffee, yogurt or functional drinks. Children can also eat breakfast cereals as sweet and crunchy snacks. According to the taste, there are light corn flakes, sweet corn flakes and salted corn flakes.

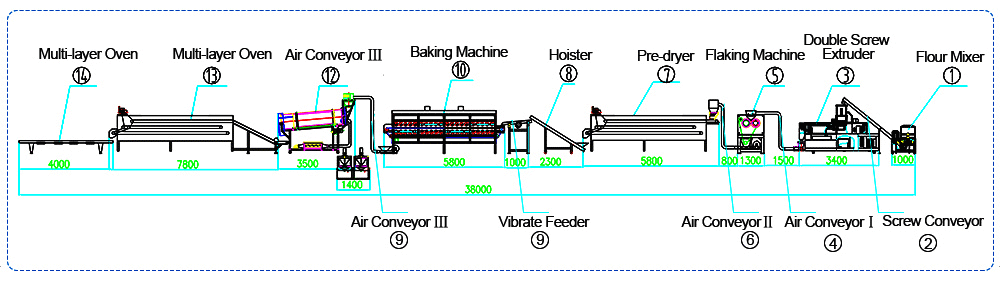

Flow Chart Of Corn Flakes Making Machine Manufacturing Breakfast Cereal Sweet Corn Flakes Processing Equipment

RAW MATERIAL→ MIXING → EXTRUSION, MATURATION AND CUTTING INTO PELLET BALLS → COOLING → AIR CONVEYING → TABLET PRESSING → AIR CONVEYING → DRYING → LIFTING → COOLING → PACKAGING

Equipment Of Corn Flakes Making Machine Manufacturing Breakfast Cereal Sweet Corn Flakes Processing Equipment

1.Flour Mixer

The function of the powder mixer is to mix the various raw materials needed for extrusion to achieve uniformity. When using, add various raw materials into the powder mixer, cover the lid, and turn on the Features: all parts of the powder mixer in contact with the material are made of stainless steel; the discharge port adopts a new handle opening structure design, and the sealing effect is good

2.Screw conveyor

Function: The screw conveyor can be conveyed both horizontally and upwards at any angle. The material is conveyed in the sealed stainless steel tube without leakage, dust, and pollution. It can send materials from the mixer to the feeder or conditioner, or directly to the feed port of the extruder.

Features of corn flakes making machine manufacturing breakfast cereal sweet corn flakes processing equipment : all parts in contact with materials are made of stainless steel or advanced surface spraying treatment, which avoids material pollution and material and equipment bonding;

3.Twin screw extruder

Main products: This equipment has a wide range of raw materials, multiple product shapes, and the extruder is composed of feeding system, extrusion system, heating system, transmission system, rotary cutting system and control system. The corn flour is fed by the feeder, and the machine is subjected to high temperature, high pressure, and high shear to expand the material to meet the quality requirements such as the required organization state. The raw material is sterilized at high temperature and high pressure during the processing process to ensure the hygiene of the product Safe;

4. Air conveyor

The air conveyor is a device that uses the wind power of a fan to transport corn flakes. It has the characteristics of low energy consumption, high efficiency, and no leakage and pollution of food in the enclosed stainless steel channel. It is more advantageous for long-distance transportation.

5. Seven-layer eight-meter oven

The heating method is electric heating, which is mainly used for baking or drying food.

This oven can bake all kinds of puffed food, corn flakes, nutritious rice food, pet food, tissue protein, peanuts, melon seeds, dates and other dried fruits

Features of corn flakes making machine manufacturing breakfast cereal sweet corn flakes processing equipment: small footprint, large drying area, small surface area, small heat dissipation, and high thermal efficiency; the insulation board and mesh belt are made of stainless steel, heating adopts electrical heating method, gas heating method, or diesel heating method.

Parameter Of Corn Flakes Making Machine Corn Flakes Manufacturing Machine

| Technical Parameter of Corn Flakes Making Machine Manufacturing Breakfast Cereal Sweet Corn Flakes Processing Equipment | ||||

| Installed capacity/kw | Actual power consumption/kw | Production capacity/kg | Equipment size /m | |

| Flour Mixer | 4 | 3 | 500 | 1.0X0.7×1.4 |

| Screw conveyor | 1.1 | 0.8 | 300-500 | 2.0X1.2X2.5 |

| Extruder | 100 | 65 | 600 | 3.8×1.0×2.0 |

| Air conveyor | 1.1 | 0.8 | 600 | 3.5X0.6X0.6 |

| oven | 86 | 40 | 600 | 8×1.3X2.7 |

Configuration Of Corn Flakes Making Machine Corn Flakes Manufacturing Machine

| Details Of Corn Flakes Making Machine Corn Flakes Manufacturing Machine | |

| 1.Material: | The entire production line of corn flakes manufacturing machine adopts domestic standards. The screw material of the twin-screw extruder is 38CrMoAl and alloy steel. The screw can be customized according to customer requirements. All equipment and food contact parts are made of stainless steel, and the outer guard plate is made of stainless steel. |

| 2.Delivery time: | Generally available in stock, if there is no production cycle, it depends on the situation. |

| 3.Payment method: | The down payment is 40%, the supplier organizes production, the production cycle is over, the customer pays 60% of the delivery, the customer can choose whether to inspect the machine |

| 4.Transportation method: | pick up the goods to the designated place of the demander |

| 5.Installation and debugging: | provide installation and debugging services. |

| 6.After-sales service: | The equipment is guaranteed for one year. If there is a quality problem, our company will send an engineer to repair it. The warranty covers the damage caused by man-made reasons. |

| 7.Personnel required: | 1 person for mixing powder, 1 person for equipment operation, 1 to 2 persons for packaging. |

ABB Motors Of Corn Flakes Making Machine Corn Flakes Manufacturing Machine

If you have special requirements for motors of corn flakes making machine, we can customize ABB motors for you. ABB motor is currently a brand with a high share of the world's motor market, with good quality, and the world's first motor quality brand.

| ABB Motors’ Configuration Of Corn Flakes Making Machine | |

| Attribute | Value |

| Power Rating | Different parts will use different power |

| Efficiency Class | IE2 |

| AC Motor Type | Induction |

| Supply Voltage | 220V/380V/415V |

| Phase | 3 |

| Output Speed | 1380 rpm |

| Number of Poles | 4 |

| Mounting Type | Foot |

| Length | 214mm |

| Rotation | Reversible |

| Maximum Output Torque | 1.25 Nm |

| Series | 3GAA |

| Depth | 151mm |

Advantage Of Corn Flakes Making Machine Corn Flakes Manufacturing Machine

The fully automatic corn flake screw puffing production line adopts advanced puffing and extrusion technology. By changing the mold and changing the production process, the operator can more easily and better produce the popular salad snacks on the market to meet the needs of the market. The production line has a small footprint, flexible configuration, easy operation and strong adaptability, and is well received by the industry.

2021 Customer Order of Corn Flakes Making Machine Corn Flakes Manufacturing Machine Form

| Customers Who Understand Corn Flakes Production Line Processing Technology | |

| 1 | Corn Flakes Production Line For Sale In Afghanistan |

| 2 | China Fully Automatic Corn Flakes Production Line For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Corn Flakes Production Line For Sale In Comoros |

| 4 | Corn Flakes Production Line For Sale In Afghanistan |

| 5 | Corn Flakes Production Line For Sale In Argentina |

| Dealed Customers Who Purchase Big Output Corn Flakes Making Machine In 2021 | |

| 1 | Customized Corn Flakes Making Machine For Sale In Congo |

| 2 | 800kg/h Corn Flakes Making Machine For Sale In Denmark |

| 3 | 1000kg/h Corn Flakes Making Machine For Sale In Congo |

| 4 | Customized High Efficiency Corn Flakes Making Machine For Sale In India |

| 5 | 1000kg/h Corn Flakes Making Machine For Sale In Denmark |

| Dealed Customer Have Plant Of Corn Flakes Making Machine In 2021 | |

| 1 | Corn Flakes Making Machine For Sale In Fiji |

| 2 | High Efficiency Corn Flakes Making Machine For Sale In Fiji |

| 3 | High Efficient Industrial Corn Flakes Production Line For Sale In Germany |

| 4 | Corn Flakes Production Line For Sale In Germany |

| 5 | Industrial Corn Flakes Production Line For Sale In Fiji |

| Dealed Customer Whose Intruduction Of Old Customer Of Corn Flakes Production Line In 2021 | |

| 1 | Stainless Steel Corn Flakes Production Line For Sale In Laos |

| 2 | Stainless Steel Corn Flakes Production Line For Sale In Lebanon |

| 3 | Corn Flakes Production Line For Sale In Lesotho |

| 4 | Automatic Stainless Steel Corn Flakes Production Line For Sale In Mali |

| 5 | Fully Automatic Stainless Steel Corn Flakes Production Line For Sale In Nauru |