Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake

As a professional corn flakes/breakfast cereal machine supplier, our automatic corn flakes machines/corn flakes production line design good manufacturing process. Automatic corn flakes breakfast cereal machinery can take corn, wheat, oats, rice, barley, rye, Buckwheat or barley and others as raw materials, to make the corn flakes/breakfast cereal for sales.

Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 20days / Corn Flakes Production Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE, ISO9001, SGS, BV |

Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake Detail Introduction :

AUTOMATIC SELF CLEANING AUTOMATIC CORN FLAKES MAKING MACHINE TWIN-SCREW EXTRUSION FOR CEREAL FLAKE DESCRIPTION

Corn flakes are processed by an extruder with a special structure. Compared with the traditional method, the output, quality, and adaptability of raw materials have been improved by one step, making it possible to strengthen vitamins and minerals and other trace elements. The corn flakes production line has the characteristics of multiple models, flexible equipment configuration, wide range of raw materials, multiple product types, and simple operation. By changing different molds and changing the production process, various puffed foods popular on the market can be produced, which is suitable for various food manufacturers.

1.Breakfast cereal/ Corn flakes is a popular food made from processed grains that is often eaten as the first meal of the day. It is eaten hot or cold, usually mixed with milk and sometimes yogurt or fruit. such as banana and strawberry, are popular additions.

2.Cereals are often fortified with vitamins good for the human body.

3.Many breakfast cereals are produced via extrusion.

TECHNICAL PARAMETERS OF SELF CLEANING AUTOMATIC CORN FLAKES MAKING MACHINE TWIN-SCREW EXTRUSION FOR CEREAL FLAKE

| Different model for sale of breakfast cereal corn flakes production line | |||

| Model | Twin Extruder Power | Output | Size (L*W*H) |

| LY65 | 30KW | 100-150g/h | 39000x1200x2200mm |

| LY70L | 37KW | 200-250kg/h | 41000x1500x2200mm |

| LY85 | 75KW | 300-500kg/h | 43000x3500x4300mm |

Corn flakes are rich in nutrition and relatively balanced. They are rare cereal breakfast foods, usually eaten with milk. As a convenient, fast, nutritious and relatively balanced food, corn flakes quickly entered thousands of households. So the automatic corn flake plant is becoming more and more popular .The corn flakes production line uses extrusion technology.

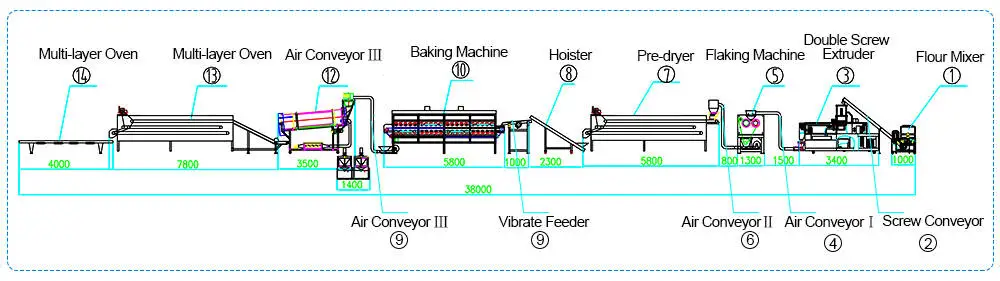

FLOW CHART OF SELF CLEANING AUTOMATIC CORN FLAKES MAKING MACHINE TWIN-SCREW EXTRUSION FOR CEREAL FLAKE

Powder Mixer → Screw Conveyor → Twin Screw Extruder → Vibrate Cooler → Dryer → Air Conveyor → Flakes Machine→ Air Conveyor → Five-Layer Pre-Dryer → Hoist → Vibration Feeder → Hot Air Dryer → Air Conveyor → Sugar Spray System → Commercial Food Dryer→Cooling Machine → (Packing Machine)

| corn flakes production line flow chart | ||

| 1 | Flour Mixer | Mixing materials |

| 2 | Screw Conveyor | Transfer Corn flakes raw materials from Mixer to Twin screw Extruder |

| 3 | Twin screw extruder | Extruding corn pellets |

| 4 | Vibrate Cooler | Cooling the corn flakes pellet |

| 5 | Air conveyor | Transfer Corn flakes pellet to flakes making machine |

| 6 | Flakes Making Machine | Flaking corn flakes pellets into corn flakes |

| 7 | Air Conveyor | Transfer corn flakes to dryer |

| 8 | Dryer | Drying process in food industry to remove moisture |

| 9 | Hoister | Transfer Corn flakes to Vibrate Feeder |

| 10 | Vibrate Feeder | Transfer Corn flakes to how air dryer evenly |

| 11 | Hot Air Dryer | High temperature roaster oven make the corn flakes much more crispy |

| 12 | Air Conveyor | Transfer Con flakes to Sugar Sprayer |

| 13 | Sugar Sprayer | Spraying sugar on corn flakes surface |

| 10 | Commercial Food Dryer | Drying again to remove sugar moisture |

| 11 | Cooling Machine | Cooling corn flakes with cooling fan |

| 12 | Corn Flakes Packaging | Packing corn flakes in bags |

CHANGE THE DIE CAN MAKE DIFFERENT SHAPE

Round balls, rings, flower, heart shape, starts, animals, alphabetic ABC or 123. Etc.

STAINLESS STEEL BREAKFAST CEREAL CORN FLAKES DRYER FEATURES

1. Multi-layer design can meet the different production capacity and snacks;

2. Frequency control, easy control the belt speed, roasting time and temperature;

3. Stainless steel material, rust free, double conveyor belt to prevent product leakage;

4. Dryer insulation design, saving energy;

5. The mode of heating has electric type,diesel oil/fuel gas type and steam type, according to the difference of product and capacity, it can suit different heat source and mod.

WHAT IS OUR ADVANTAGE OF THE FULL AUTOMATIC BREAKFAST CEREAL CORN FLAKES PLANT

| Advantages of Corn Flakes Production Line | |

| 1 | Adopting turbine and worm to adjust the gap of pressure roller, the adjustment effect is accurate and balanced |

| 2 | The alloy coating on the surface of the pressure roller has high hardness and greatly improves the service life |

| 3 | Equipped with an adjustable scraper to prevent the product from sticking to the pressure roller |

| 4 | Equipped with pressure roller oil injection system to prevent the product from sticking to the pressure roller |

| 5 | The tablet press can be supplied with cold water and has water-cooled pipes to prevent the press roller from overheating and affect product characteristics |

| 6 | The high-temperature oven (it can be called a through-type oven) has an openable and closeable structure for the inlet and outlet guards to facilitate maintenance and cleaning |

| 7 | The box body adopts double-layer aluminum silicate insulation board. |

| 8 | The pipeline adopts aluminum silicate insulation layer. |

| 9 | 6 groups of hot air blowers blow high-temperature hot air from the upper and lower parts of the material to the material, and the baking is even |

| 10 | Each group of hot air blowers have independent air outlet ducts and return air ducts, with higher thermal efficiency |

BREAKFAST CEREAL CORN FLAKES MAKING MACHINE MANUFACTURERS:

We share our corn flakes production line knowledge to process healthy and balanced products made with wholegrain cereals or including a mix of multi-grains like corn, wheat, oats, rice, barley, rye, Buckwheat or barley. Our automated corn flakes production line is used to produce consistently high quality products while keeping the same organoleptic characteristics as traditional flakes.Corn flakes manufacturing process change molds and choose the right process to produce circles, balls, sheets, stars, letters and other products,and produce core filling snack food, filling biscuit ,nutrition breakfast, corn flakes and other puffed foods.

APPLICATION OF CORN FLAKE PLANT MACHINE

Breakfast cereal corn flakes production line can make corn flakes,and also can make other grain flakes,and breakfast cereals.

2021 Customer Order of Corn Flakes Processing Line Form:

| Customers Who Understand Corn Flakes Production Line Processing Technology | |

| 1 | Corn Flakes Production Line For Sale In Afghanistan |

| 2 | China Fully Automatic Corn Flakes Production Line For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Corn Flakes Production Line For Sale In Comoros |

| 4 | Corn Flakes Production Line For Sale In Afghanistan |

| 5 | Corn Flakes Production Line For Sale In Argentina |

| Dealed Customers Who Purchase Big Output Corn Flakes Making Machine In 2021 | |

| 1 | Customized Corn Flakes Making Machine For Sale In Congo |

| 2 | 800kg/h Corn Flakes Making Machine For Sale In Denmark |

| 3 | 1000kg/h Corn Flakes Making Machine For Sale In Congo |

| 4 | Customized High Efficiency Corn Flakes Making Machine For Sale In India |

| 5 | 1000kg/h Corn Flakes Making Machine For Sale In Denmark |

| Dealed Customer Have Plant Of Corn Flakes Making Machine In 2021 | |

| 1 | Corn Flakes Making Machine For Sale In Fiji |

| 2 | High Efficiency Corn Flakes Making Machine For Sale In Fiji |

| 3 | High Efficient Industrial Corn Flakes Production Line For Sale In Germany |

| 4 | Corn Flakes Production Line For Sale In Germany |

| 5 | Industrial Corn Flakes Production Line For Sale In Fiji |

| Dealed Customer Whose Intruduction Of Old Customer Of Corn Flakes Production Line In 2021 | |

| 1 | Stainless Steel Corn Flakes Production Line For Sale In Laos |

| 2 | Stainless Steel Corn Flakes Production Line For Sale In Lebanon |

| 3 | Corn Flakes Production Line For Sale In Lesotho |

| 4 | Automatic Stainless Steel Corn Flakes Production Line For Sale In Mali |

| 5 | Fully Automatic Stainless Steel Corn Flakes Production Line For Sale In Nauru |