Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line

As a professional corn flakes/breakfast cereal machine manufacturer, our automatic corn flakes machines/breakfast cereal production line design good manufacturing process. Automatic corn flakes breakfast cereal machinery can take corn, wheat, oats, rice, barley, rye, Buckwheat or barley and others as raw materials, to make the corn flakes/breakfast cereal for sales.Corn flakes are common breakfast cereals in the world. The raw material for processing corn flakes is corn flour, which has high horny endosperm content, high transparency after starch gelatinization, and good product appearance. When eating corn flakes, prepare corn flakes with boiling water. If you put corn flakes in the soup, you can make corn flake soup. If you add milk to corn flakes, it tastes good. The corn flakes currently produced in my country include light corn flakes, sweet corn flakes and salted corn flakes.

Corn Flakes Manufacturing Cereal Production Line

Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Warranty | 1 YEAR |

| Material | Stainless Steel 304 |

| Certification | CE BV ISO 9001 |

| After-sales Service Provided | Engineers available to service machinery overseas |

Stable Pre-Formtion Corn Flakes Manufacturing Cereal Production Line Processing Line Detail Introduction :

We are a professional Corn Flakes Manufacturing Cereal Production Line Processing Line manufacturer. Our fully automatic corn flakes/breakfast cereal production line is designed with good manufacturing technology and is well received by customers. The automatic corn flake breakfast cereal machine can use corn, wheat, oats, rice, barley, rye, buckwheat or barley as raw materials to make delicious corn flakes/breakfast cereals for sale.

Details of Fully Automatic Corn Flakes/Breakfast Cereal Production Line

| Details of Automatic Corn Flakes Production Line | |

| Product name | Fully Automatic Corn Flakes/Breakfast Cereal Production Line |

| Brand Name | LOYAL |

| Min.Order Quantity | 1 |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Warranty | 1 YEAR |

| Material | Stainless Steel 304 |

| Certification | CE BV ISO 9001 |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Features: | Full Automatic And Easy Operate |

| Heating method: | Electricity, gas, steam, diesel |

Corn flakes are common breakfast cereals in the world. The raw material for processing corn flakes is corn flour, which has high horny endosperm content, high transparency after starch gelatinization, and good product appearance. When eating corn flakes, prepare corn flakes with boiling water. If you put corn flakes in the soup, you can make corn flake soup. If you add milk to corn flakes, it tastes good. The corn flakes currently produced in my country include light corn flakes, sweet corn flakes and salted corn flakes. Because corn contains large germs, it will affect starch gelatinization and corn flakes morphology, and bring inconvenience to processing operations. Therefore, we use corn meal that has been peeled and degerminated as the raw material for the production of corn flakes.

Brief Introduction of cornflakes:

Breakfast cereal is a breakfast food with high nutritional value. They usually use corn flour and other grains as the main raw materials. And they are mixed, squeezed, pressed, dried, baked at high temperature, coated with sugar. Then cooled to make crispy and sweet chips. Breakfast cereals are mainly used for breakfast with milk coffee. And it can also be used as casual snacks. This fully automatic breakfast cereal production line can produce breakfast cereal products of various shapes. Such as circle shape, small ball, moon shape, etc

TECHNICAL PARAMETER OF CORN FLAKES PRODUCTION LINE

| Technicial Parameter of Fully Automatic Corn Flakes/Breakfast Cereal Production Line | ||

| Model | Power Consumption | Output |

| LY65 | 30kw | 100-150g/h |

| LY70L | 37kw | 200-250kg/h |

| LY75 | 75kw | 300-500kg/h |

| LY85 | 85kw | 500-800kg/h |

| LY95 | 105kw | 800-1000kg/h |

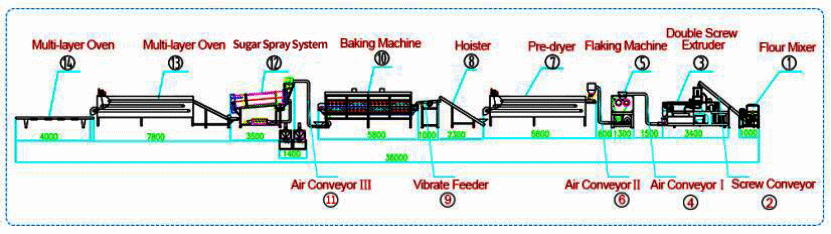

FLOW CHART OF CORN FLAKES PRODUCTION LINE

Advanced industrial equipment and assembly lines have formed the following production process of ourl breakfast cereal corn flakes production line:

Raw materials (Corn Flour, Sugar, Salt, Other Nutrients) → Mixer→ Screw Conveyor → Twin-Screw Extruder with cooling system →-Vibrate Cooler→ Air Conveyor →Drying Roller → Air Conveyor → Big Flake Machine with Cooling System → Air Conveyor → Multi-layer Dryer→ Hoister → Vibrant Feeder → Hot Air Roaster → (Melting Sugar Jar → Sugar Coating System → Drying Machine) → Cooling Conveyor

| Equipment List of Corn Flakes Making Machine | |

| Equipment Name | Introduction of Fully Automatic Corn Flakes/Breakfast Cereal Production Line |

| Mixer | It is used to mix corn flour with some additives and a certain amount of water. |

| Screw conveyor | It transports the mixed raw materials to the feeding hopper of the extruder to ensure convenient and fast feeding |

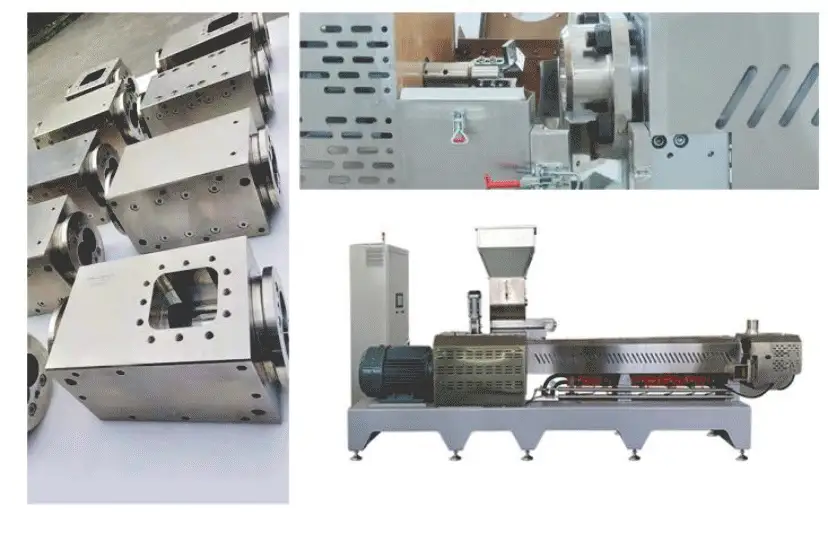

| Twin Screw Extruder | It can extrude the raw materials in a high-pressure environment, and produce different shapes by adjusting the process and changing the mold. |

| Vibrating feeder | It spreads the products through a vibrating screen to avoid sticking together. |

| Air conveyor | It transports the product to the oven. |

| Multi-layer dryer | The baking time of the high-temperature oven can be adjusted according to the speed, it can reduce the particle moisture and increase the shelf life. |

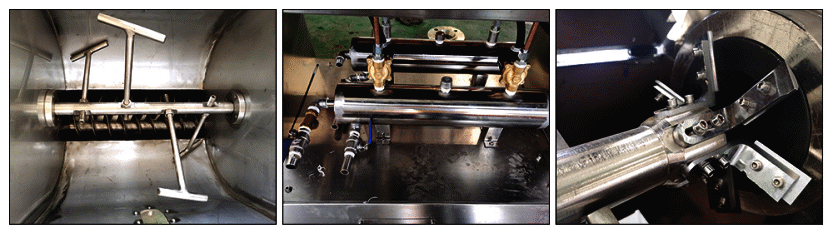

| Big Flake Machine | It is used to press the spherical corn balls from the extruder into corn flakes. We use special processing technology, the surface hardness can reach 65 or more, the roller has a longer service life, and the roller has a very high processing accuracy. |

| Cooling conveyor | The packaging quality can be guaranteed by cooling to room temperature. |

According to the customer's choice, we can configure the dryer with electricity, gas, diesel or steam heating. In addition, if the customer needs to spray sugar on the corn flakes, we will provide a sugar spray system to facilitate the customer's choice.

WHAT CAN WE GET FROM THE STABLE PRE-FORMTION CORN FLAKES MANUFACTURING CEREAL PRODUCTION LINE PROCESSING LINE?

By adding grain flours of different colors to the raw materials, corn flakes of different shapes can be obtained. At the same time, if the screw and mold are replaced, we can use this Fully Automatic Corn Flakes/Breakfast Cereal Production Line to produce delicious and rich breakfast cereals.

WHAT IS THE TECHNICAL ADVANTAGES OF STABLE PRE-FORMTION CORN FLAKES MANUFACTURING CEREAL PRODUCTION LINE PROCESSING LINE?

1. Fully Automatic Corn Flakes/Breakfast Cereal Production Line is energy-saving: the material has a low water usage rate in the production process, the energy consumption of the oven drying process is reduced, and the heat energy utilization rate is high, which is in line with the sustainable development strategy of mankind.

2. Fully Automatic Corn Flakes/Breakfast Cereal Production Line protects the environment: When the material is in the production state, no waste water, waste gas or waste residue will be produced during the production process of the machine connection. And there is no loss of raw materials in this process.

3. Fully Automatic Corn Flakes/Breakfast Cereal Production Line is cost-saving: our corn flakes production line requires less labor per unit product, less equipment space, and large production capacity. Its performance is very stable, and the product quality fluctuates little, and it has been at a high quality level.

DETAILS OF THE CORN FLAKES MAKING MACHINE

We have more than 15 years of experience in the development of advanced twin-screw extruders. Almost all extruded products include corn flakes, breakfast cereals, aquatic feed, pet food, and any problems in production can be solved.

2021 Customer Order of Corn Flakes Production Line Form:

| Customers Who Understand Corn Flakes Production Line Processing Technology | |

| 1 | Corn Flakes Production Line For Sale In Afghanistan |

| 2 | China Fully Automatic Corn Flakes Production Line For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Corn Flakes Production Line For Sale In Comoros |

| 4 | Corn Flakes Production Line For Sale In Afghanistan |

| 5 | Corn Flakes Production Line For Sale In Argentina |

| Dealed Customers Who Purchase Big Output Corn Flakes Making Machine In 2021 | |

| 1 | Customized Corn Flakes Making Machine For Sale In Congo |

| 2 | 800kg/h Corn Flakes Making Machine For Sale In Denmark |

| 3 | 1000kg/h Corn Flakes Making Machine For Sale In Congo |

| 4 | Customized High Efficiency Corn Flakes Making Machine For Sale In India |

| 5 | 1000kg/h Corn Flakes Making Machine For Sale In Denmark |

| Dealed Customer Have Plant Of Corn Flakes Making Machine In 2021 | |

| 1 | Corn Flakes Making Machine For Sale In Fiji |

| 2 | High Efficiency Corn Flakes Making Machine For Sale In Fiji |

| 3 | High Efficient Industrial Corn Flakes Production Line For Sale In Germany |

| 4 | Corn Flakes Production Line For Sale In Germany |

| 5 | Industrial Corn Flakes Production Line For Sale In Fiji |

| Dealed Customer Whose Intruduction Of Old Customer Of Corn Flakes Production Line In 2021 | |

| 1 | Stainless Steel Corn Flakes Production Line For Sale In Laos |

| 2 | Stainless Steel Corn Flakes Production Line For Sale In Lebanon |

| 3 | Corn Flakes Production Line For Sale In Lesotho |

| 4 | Automatic Stainless Steel Corn Flakes Production Line For Sale In Mali |

| 5 | Fully Automatic Stainless Steel Corn Flakes Production Line For Sale In Nauru |