Automatic Twin Screw Extruder Machine Production Line

One of the largest Twin Screw Extruder Machine manufacturers in China. All types of Twin Screw Extruder Machine engineering projects with great prices and high quality of Twin Screw Extruder Machine . 116 countries and regions Twin Screw Extruder Machine Manufacturers' Technology. Over 20 years experience in Twin Screw Extruder Machine .Our Screw Extruder Machine design good manufacturing process. Twin Screw Extruder Machine can take Corn, potato grains and others as raw materials, to make the Bread Crumbs, corn puff, Corn Snack, Puffed Rice for sale.This has features of lots of types, flexible collocation, extensive applied materials, various products and easy operation.As a professional manufacturer of corn puffed snack production line, we have been in the field of puffed extruder machine for many years. We are the supplier of corn puff making machine, our corn puffed extruder machine design good manufacturing process.

Automatic Twin Screw Extruder Machine Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Trial Demonstratio | Welcome You To Visit Us At Any Time For Machinery |

| After-sales Service | Engineers available to service machinery overseas |

| baking fuel | electric,gas,diesel,LPG |

| Automation | Fully Automatic |

| Machines Materials | stainless steel |

Automatic Twin Screw Extruder Machine Production Line Detail Introduction :

The automatic Twin Screw Extruder Machine Production Line developed by the twin-screw extruder manufacturer has superb craftsmanship and decades of production experience. It can use biological sources or synthetic raw materials to continuously produce food with a delicate export sense and fine structure. The full-automatic twin-screw extruder production line is used to produce various food and feed products, etc. Our multi-functional automatic twin screw extruder machine production line is for your breakfast cereals, food ingredients, pet food and aquatic feed products, puffed food, Processes such as tissue protein provide flexible and reliable processing.

TECHNICAL PARAMETER OF TWIN SCREW EXTRUDER MACHINE PRODUCTION LINEFOR SALE

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

| LY65 | 47KW | 30KW | 180kg/h | 3500x950x1850mm |

| LY70 | 53KW | 37KW | 200-250kg/h | 3200x760x2000mm |

| LY75 | 98KW | 75kw | 200-500kg/h | 5200*1100*2800mm |

| LY85 | 99KW | 75KW | 500kg/h | 3800*1100*2350mm |

Main Features Of Automatic Twin Screw Extruder

| 1 | The automatic twin-screw machine consists of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, a lubrication system and a control system. |

| 2 | The screw is made of alloy steel, processed by a special process, has high strength, wear resistance, and a longer screw life. A single device adopts a modular structure, which can be combined according to different productions. |

| 3 | The gear box has an automatic lubrication function to ensure the safe operation of the twin-screw extruder and extend the life of the gear. |

| 4 | The visualized automatic temperature control system makes the temperature control more intuitive and the parameters clearer. |

| 5 | The double screws have a self-cleaning function, and there is no need to remove the screws when cleaning. |

| 6 | According to different products, we can change the screw length to diameter ratio to meet different production processes. |

| 7 | The twin-screw extruder feed system, main drive system, and rotary cutting system all adopt frequency conversion speed regulation, with strong power, safe and electricity-saving. |

| 8 | Customers can choose different models and configurations to process different products. Such as puffed snacks, sandwich snacks, fried snacks, baby oatmeal, breakfast oatmeal snacks, pet feed, nutritious rice, etc. |

How does a twin screw extruder work?

The twin-screw extruder is developed on the basis of the single-screw extruder. Due to its good feeding performance, mixing and plasticizing performance, exhaust performance, extrusion stability, etc., it has been widely used in extruded products.

The twin-screw extruder is composed of two co-rotating screws that mesh with each other and are installed on the spline shaft of the barrel. Due to the wide range of screw and barrel design, various screw profiles and process functions can be set according to process requirements. Therefore, the twin-screw extruder technology can ensure highly flexible transportation, compression, mixing, cooking, shearing, heating, cooling, pumping, molding, etc. The main advantage of the intermeshing co-rotating twin-screw extruder is its excellent mixing ability, which gives the extruded product excellent characteristics.

Daily Maintenance Of Twin Screw Extruder

| 1 | After 500 hours of use, there will be iron filings or other impurities in the gearbox. Therefore, the gear should be cleaned and the gearbox lubricant should be replaced. |

| 2 | After using for a period of time, perform a comprehensive inspection of the extruder to check the tightness of all screws. |

| 3 | If there is a sudden power failure during production, the main drive and heating stop, when the power supply is restored, each section of the barrel must be reheated to the specified temperature and kept for a period of time before the extruder can be started. |

| 4 | If the steering of the gauge and pointer is found to be full, check whether the contact of the thermocouple etc. is in good condition. |

ADVANTAGES OF TWIN SCREW EXTRUDER PRODUCTION LINE FOR SALE

| Automatic type | Fully automatic. |

| Highly efficient | High efficiency, hygiene, safety.From mixing material to package 2-3 workers are enough. |

| Factory environment | Without leak of powder dust. |

| Raw material of finished powder | More raw materials can be used in one production,Such as rice flour, corn flour, soybean flour, oats, buckwheat, etc., and various nutrients can be added at the same time. |

| Finished powder | After expansion, nutrients are easily absorbed by human body. |

| Taste of finished powder | Delicate taste, usage widely. |

Our twin-screw extruder has the advantages of very good feeding performance, strong exhaust performance, and high extrusion stability.

We are adhering to the tenet of "Quality as our duty, quality for survival, and integrity for development".

The professional R&D and design team, the equipment structure is reasonable, the operation is more convenient, and the labor cost is reduced for customers.

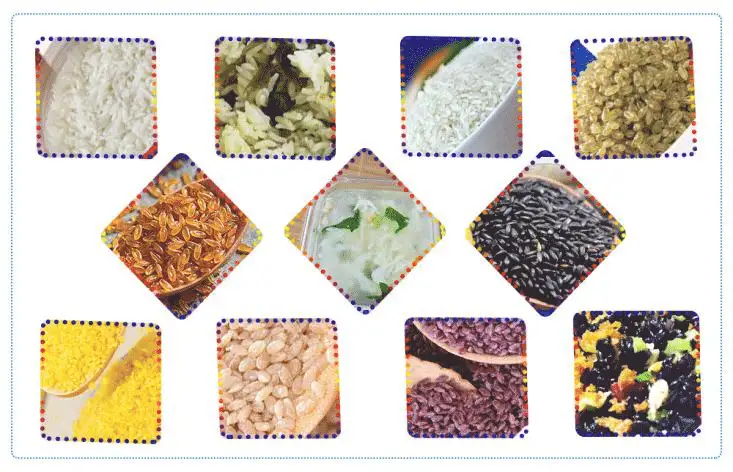

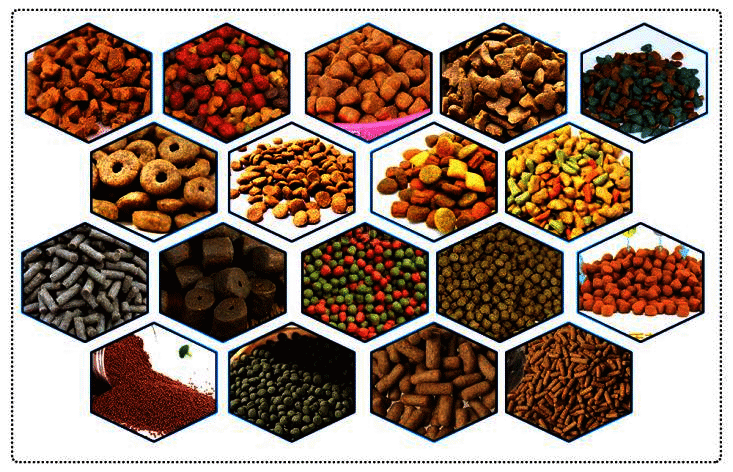

FINISHED PRODUCTS PICTURES

By adjusting the barrel and screw structure of the twin-screw extruder, diversified modified starch products such as baby rice noodles, pet feed, and soybean meal can be produced. The baby artificial rice production line produced by our company has stable performance, compact structure, simple operation, and realizes one-time and one-time fully automated production, which is well received by customers.

FRIED SNACK ---

NUTRITION RICE---

PET FOOD---

CORN FLAKES---

SOYA PROTEIN---

NUTRITION POWDER---

2021 Snacks Making Machine Customer Cases

| Customer cases for snacks making machine for factory in 2021 | |

| 1 | 1t/h cost of snacks making machine sold in russia customer’s factory |

| 2 | 1t/h industrial snack maker machine price for factory for sale in puerto rico puffy snack plant agent |

| 3 | 1t/h industrial snack maker machine price for sale in bolivia customer’s factory |

| 4 | Senegal 1t/h industrial fully automatic industrial snack maker machine |

| 5 | 1t/h snacks making machine price for sale in côte d'ivoire |

| 6 | China 300t/year industrial fully automatic snacks making machine price |

| Customer case of snack food making machine at 2021 | |

| 7 | 1t/h microwave drying equipment for factory in uzbekistan puffy snack machinery agent |

| 8 | 1000kg/h snack maker machine for sale in senegal customer’s factory |

| 9 | Mozambique 1t/h fully automatic snacks making machine price |

| 10 | Bangladesh 2t/h fully automatic snacks making machine price |

| Dealed customer have technology of corn puff extruder machine at 2021 | |

| 11 | 1t/h thai snack food making machine for factory |

| 12 | Uzbekistan 1t/h fully automatic corn puff extruder machine |

| 13 | Usa 1t/h corn puff extruder machine |

| 14 | 800kg/h industrial snacks making machine for sale in nigeria customer agent |