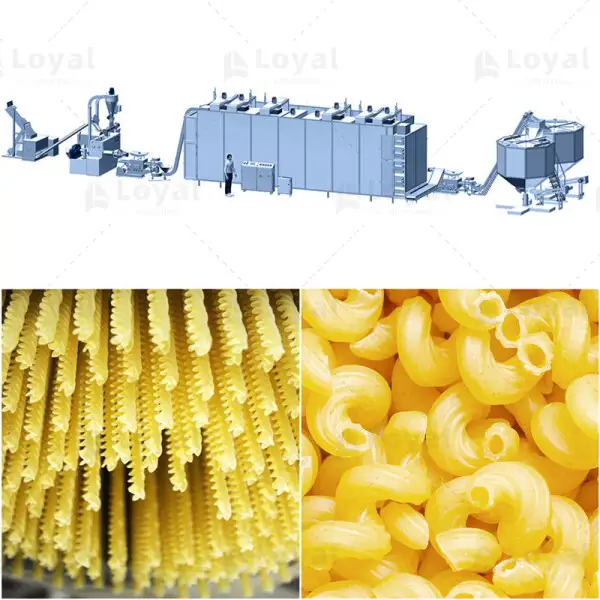

PLC Control Vacuum Pasta Production Line

One of the largest fully automatic vacuum pasta processing line manufacturer in China ,we can offer small, medium and large fully automatic vacuum pasta processing line for sale.

The PLC control vacuum pasta processing line has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements. The Pasta vacuum extrusion pasta noodle maker making machine is mainly use flour, starch as the raw material, through different kinds of extrusion mold to make different kinds of pasta, spaghetti, snacks etc. The raw material also mixed with vegetable juice to produce different flour and color pasta. Macaroni Spaghetti Pasta Extruder Pasta Making Machineis suitable for bakery, restaurant, snack and food processing plant. This line is characterized by unique technique, rational configuration, high automation and stable performance.

PLC Control Vacuum Pasta Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

PLC Control Vacuum Pasta Production Line Detail Introduction :

The industrial PLC control vacuum pasta processing line adopts samolina flour, wheat flour, potato starch, potato powder, and corn starch as main materials, to produce a variety of frying & boiling food in different shapes, which are popular in the market, such as crisp pea, shell, screw, square tube, round tube, and wave. This line is characterized by unique technique, rational configuration, high automation and stable performance.

MAIN FEATURE OF PLC CONTROL VACUUM PASTA PROCESSING LINE

Main Feature Of PLC Control Vacuum Pasta Processing Line | |

| 1 | The linear structure is simple and easy to install and maintain. |

| 2 | Pneumatic part, electrical part and operation part all adopt advanced world-renowned brand components. |

| 3 | The high pressure double crank controls the mold opening and closing. |

| 4 | The operation is automated, intelligent, and pollution-free |

| 6 | Use the connector to connect with the air conveyor, which can be directly connected to the filling machine in series. |

TECHNICAL PARAMETER OF PLC CONTROL VACUUM PASTA PROCESSING LINE

Technical Parameter Of PLC Control Vacuum Pasta Processing Line | |||

| Model | LY-100 Pasta Food Line | LY-130 Macaroni Production Line | LY-150 Pasta Extruder |

| Installed Power | 97.0KW | 180.0KW | 230.00KW |

| Power Consumption | 58.0KW | 150.0KW | 180.0KW |

| Production Capacity | 100-120KG/H | 180-240KG/H | 250-300 |

| Dimension | 18.0*2.0*2.5M | 25.0*2.0*2.5M | 35.0*2.0*2.5 |

APPLICATION OF PLC CONTROL VACUUM PASTA PROCESSING LINE

Application Of PLC Control Vacuum Pasta Processing Line | |

| 1 | The Pasta vacuum extrusion pasta noodle maker making machine is mainly use flour, starch as the raw material, through different kinds of extrusion mold to make different kinds of pasta, spaghetti, snacks etc. |

| 2 | The raw material also mixed with vegetable juice to produce different flour and color pasta. Macaroni Spaghetti Pasta Extruder Pasta Making Machineis suitable for bakery, restaurant, snack and food processing plant. |

| 3 | Snacks: Producing Shell type crisp, straight macaroni-style pasta, tremella type crisp, penne,five-pointed star crisp, butterfly shape pasta, cat ear type crisp, lantern type crisp, peanut type snack, large and small hollow pipe type snack and so on. |

| 4 | Pasta: Producing Hollow noodles , spiral macaroni, shells noodles,Tremella noodles, cat ear noodles,vegetables noodles and so on. |

WHICH MARKET DID THE LOYALSMALL SCALE PLC CONTROL VACUUM PASTA PROCESSING LINE SOLD?

LOYAL's share of fully automatic vacuum pasta processing line exported to international markets has steadily increased. According to the export goods trade data in 2021, Loyal's export market share in the international market is 86.5%, of which the PLC control vacuum pasta processing line export market share is 19.8%, the export market share in the Americas is 31.2%, and the export market share in Asia is 35.5%. If you are interested in a meat dryer, please contact us today, we offer you the most cost-effective turnkey solution.

| Customer Have Formula Request Of Vacuum Pasta Production Line Manufacturers | |

| 1 | China 300t/Year Pasta Macaroni Making Machine |

| 2 | 1T/H PLC Control Vacuum Pasta Processing Line For Sale In Puerto Rico |

| 3 | 1T/H Fully Automatic Vacuum Pasta Processing Line For Sale In Bolivia Agent |

| 4 | 800Kg/H Pasta Making Machine Automatic Line For Sale In Argentina Factory |

| 5 | 2T/H Fully Automatic Vacuum Pasta Processing Line For Sale In Benin |

| 6 | 2T/H PLC Control Fully Automatic Vacuum Pasta Processing Line for Sale In British Indian Ocean Territory Manufacturer |

| 7 | 2T/H PLC Control Fully Automatic Vacuum Pasta Processing Line For Sale In Chile |

| Cooperated Customer For Laboratory Machine Of PLC control vacuum pasta processing line | |

| 1 | Senegal 200Kg/H Industrial PLC Control Pasta Macaroni Making Machine |

| 2 | 100-200Kg/H Pasta Vacuum Processing Equipment For Sale In Côte d'Ivoire |

| 3 | 300-400Kg/H Pasta Vacuum Processing Equipment For Sale In Sold In Russia Manufacturer |

| 4 | 500Kg/H Pasta Processing Vacuum Equipment For Sale In Sold In Denmark |

| 5 | 600Kg/H PLC Control Vacuum Pasta Macaroni Making Machine For Sale In Dominica |

| 6 | 100-200Kg/H PLC control vacuum pasta processing line For Sale In Egypt Agent |

| 7 | 300-400Kg/H PLC control vacuum pasta processing line For Sale In Sold In Ethiopia |

| Cooperated Customer Request Engineer Installation At 2021 | |

| 1 | 1T/H PLC Control Vacuum Pasta Macaroni Making Machine For Sale In Uzbekistan |

| 2 | 1000kg/h Industrial Fully Automatic Vacuum Pasta Processing Line For Sale In Senegal |

| 3 | Mozambique 1T/H Fully Automatic Vacuum Pasta Processing Line Machine Agent |

| 4 | 1T/H Thai PLC Control Vacuum Pasta Macaroni Making Machine Machine |

| 5 | Uzbekistan 1T/H PLC Control Vacuum Pasta Macaroni Making Machine Machine |

| 6 | 2T/H Fully Automatic Vacuum Pasta Processing Line For Sale In Germany |

| 7 | 2T/H Fully Automatic Vacuum Pasta Processing Line For Sale In Guinea |

| Cooperated Customer With Fully Automatic Vacuum Pasta Processing Line Technology At 2021 | |

| 1 | Nigeria 500Kg/H Fully Automatic Vacuum Pasta Processing Line |

| 2 | Austria Sells Fully Automatic Vacuum Pasta Processing Line 1000kg/h |

| 3 | Microwave Dryer Machine For Waste Water Dehydrated Vegetables Powder For Sale In Pakistan 1000kg/h |

| 4 | 1T/H Fully Automatic Vacuum Pasta Processing Line For Sale In India |

| 5 | 2T/H Fully Automatic Vacuum Pasta Processing Line For Sale In Israel Manufacturer |

| 6 | 2T/H PLC Control Pasta Macaroni Making Machine Machine For Sale In Jamaica |

| 7 | 2T/H PLC Control Pasta Macaroni Making Machine Machine For Sale In Morocco |