Pasta Macaroni Making Machine Single Screw Extruder with Capacity 200~250kg per hour

Industrial full-automatic pasta thread pasta macaroni making machine macaroni pasta machine manufacturer uses durum wheat flour as raw material, is a kind of food that is extruded, matured, shaped, cut, dried, and cooled. There are pea-shaped, shells, spirals, Square tube, round tube, and wave shapes. Through market research and our own technology, our company has improved the performance of the production line, making it easier for operators to operate the equipment, and the process is more complete. Industrial automatic pasta macaroni production line macaroni pasta machine pasta machine macaroni pasta machine manufacturer is an indispensable food production equipment for every person in the snack food industry.The pasta macaroni production line has unique technology, reasonable configuration, high degree of automation and stable performance.

Pasta Macaroni Making Machine Single Screw Extruder with Capacity 200~250kg per hour Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Pasta Macaroni Making Machine Single Screw Extruder with Capacity 200~250kg per hour Detail Introduction :

Industrial full-automatic pasta thread pasta macaroni making machine macaroni pasta machine manufacturer uses durum wheat flour as raw material, is a kind of food that is extruded, matured, shaped, cut, dried, and cooled. There are pea-shaped, shells, spirals, Square tube, round tube, and wave shapes. Through market research and our own technology, our company has improved the performance of the production line, making it easier for operators to operate the equipment, and the process is more complete.

Industrial automatic pasta macaroni production line macaroni pasta machine pasta machine macaroni pasta machine manufacturer is an indispensable food production equipment for every person in the snack food industry.

The pasta macaroni production line has unique technology, reasonable configuration, high degree of automation and stable performance.

1.Description Of Pasta Macaroni Making Machine:

Macaroni pasta is produced by Vacuum pasta extruder machine through extruding cooking; the pellet can be different shapes like shell, spiral, square tube, circle tube, and so on.

2.Specifications Of Pasta Macaroni Making Machine:

| Specifications Of Pasta Macaroni Making Machine | ||

| Parameter Model | LY100 | LY150 |

| Pasta Machine | Pasta Machine | |

| Install Power | 90 KW | 120 KW |

| Consumption Power | 75 KW | 96 KW |

| Output | 120-150 KG/H | 220-250 KG/H |

| Dimension | 22000×1300×2200 MM | 26000×1300×2200 MM |

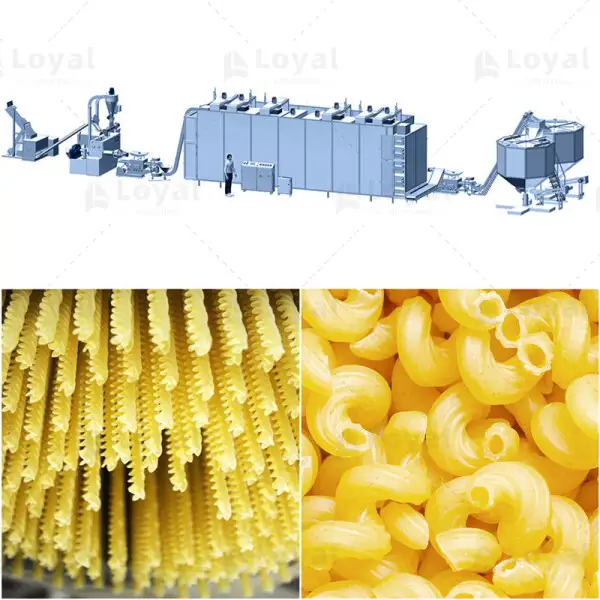

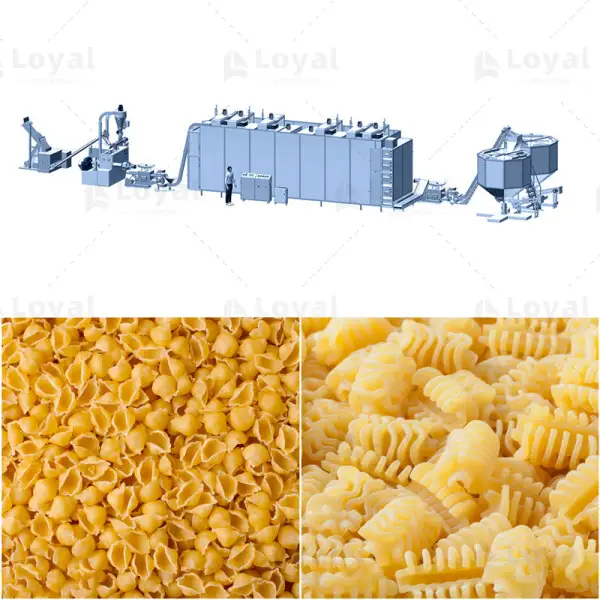

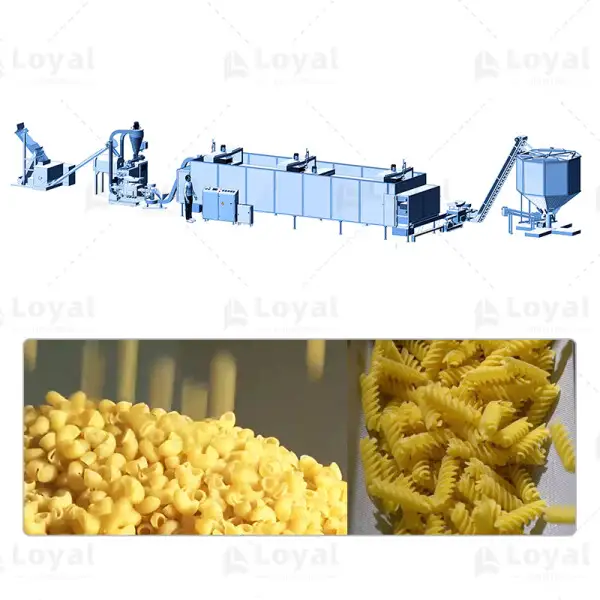

3.Sample Photos Of Pasta Macaroni:

This industrial pasta extruder machine can be used to produce shell, spiral, square tube, circle tube shapes by changing the mould easily.

4.Raw Materials

Adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

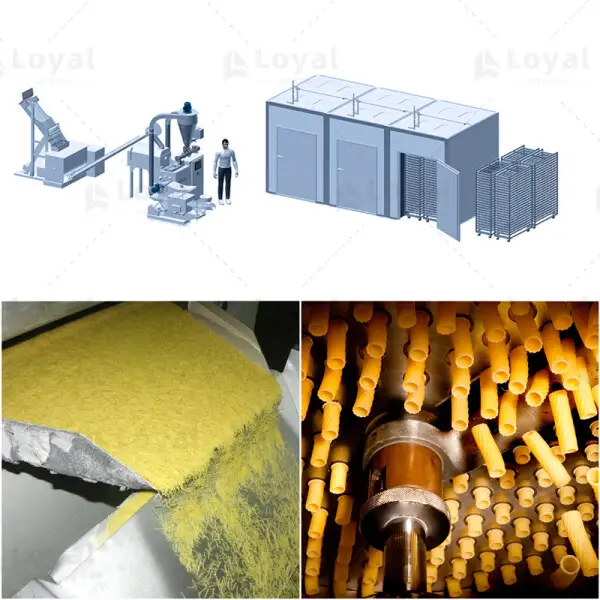

Flow chart of pasta macaroni production line:

Mixing system--- Vacuum Extrusion system----Cutting system---Drying system---Cooling system --Packing system

![]() 5.Main Features Of Pasta Macaroni Making Machine:

5.Main Features Of Pasta Macaroni Making Machine:

| Main Features Of Pasta Macaroni Making Machine: | |

| Vacuum extrusion (230 width) molding: | The dough sheet is produced while vacuuming, which can make a very dense dough. |

| Chip molding: | Support high-density chip molding. Use traditional production lines to produce noodles. |

| Patches formed for various purposes: | A multifunctional machine suitable for many applications because the machine can form noodle sheets with suitable ingredients. |

| Save space: | It can save space by eliminating compound mills, tandem mills, etc. |

| Equipped with "air locker" vacuum chamber: | It has the function of vacuum degassing and creates a completely sealed space to achieve the highest vacuum degree. |

We have Low price commercial industrial electric spaghetti macaroni pasta macaroni making machine. Our Pasta Extrusion Machinery can extrude up to 300 kg/hr. Pasta Making extruders mix and extrude the raw material in vacuum situation. This makes the Pasta smooth and translucent.

6.More Details Of Pasta Macaroni Production Line:

| Details Of Pasta Macaroni Production Line: | |

| MOQ | 1 set |

| Supply Ability | 20 sets per Month |

| Shipping Port | Qingdao port, Shandong, China |

| Packing Details | Fumigation-free wooden case outside, stretch film inner |

| Relevant Spare Parts | free, delivery with processing line |

| Guarantee | Within 12 months |

| Oversea Service | Provide installation and commissioning after machine arrived your factory |

| Payment Terms | 30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment. |

| Delivery Time | 30 days after receipt the deposit |

| Pre-Shipment | When it finished, we will invite you to our company to inspect machines, when no problem, we will arrange the shipment |

7.The Difference Between Ordinary Pasta Extruder Machine And Vacuum Pasta Extruder Machine:

(1)The raw material itself contains a lot of air, and there is also reserve air in the barrel. If an ordinary extruder is used, this situation will cause many bubbles to appear inside the pasta product, and the pasta will become brittle and black.

(2)Our extruders produced by European and American technology all use vacuum technology. Our vacuum extruder can produce chewy and shiny pasta to meet customer needs.

8.What Is A Vacuum Pasta extruder machine?

1 Change the design and structure of the screw

2 Combine the vacuum with the barrel to extract the air in the barrel to maintain a vacuum in the production process

3 The filter device keeps the vacuum pump in the clean pump

9.Pasta Macaroni Making Machine Sales Market As Follow:

Our company has already exported countries:

| Pasta Macaroni Making Machine For Sale: | |

| Asia Market | Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabia, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan |

| European Market | Russia, Bulgaria, Ukraine, Britain, France, Germany, Spain, Portugal |

| African Market | Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe |

| North and South America Market | Canada, Brazil, Bolivia, Mexico, Guatemala, Belize, El Salvador, Honduras, Panama, Bahamas, Cuba, Jamaica |

FAQ:

Q. How much does the spaghetti production line occupies?

A. Usually 26-30 meters.

Q. How many workers does the pasta production line need?

A. 2-4 workers

Q. What types of products can the pasta macaroni production line do?

A. All shells, spirals, Square tube, round tube, and wave shapes

Q. For whom is the pasta machine suitable for purchase?

A. Suitable for all home production, small factories, large factories and other manufacturers

Which Market Did The Loyal Spaghetti Line Sold?

Customer Case Of Spaghetti Pasta Production Line At 2021 | ||

1 | Old thailand Customer of 500kg/ h Automatic New Type Spaghetti Pasta Production Line in new Pasta Processing Plant | |

2 | 1T/H Tough Spaghetti Pasta Production Line For Sale in Puerto Rico | |

3 | 1T/H Crisp Spaghetti Production Line For Sale in Bolivia | |

Dealed Customer Have Technology Of Spaghetti Pasta Production Line At 2021 | ||

1 | Senegal 1T/H Industrial Spaghetti Production Line | |

2 | 1T/H Spaghetti Machine for Sale in Côte d'Ivoire | |

3 | 1T/H Industrial Spaghetti Equipment Sold in Russia | |

Dealed Customer Have Formula Of Automatic Spaghetti Process Line At 2021 | |

1 | 1000kg/h Industrial Automatic Spaghetti Machine For Sale In Senegal |

2 | Mozambique 1t/h Industrial Spaghetti Manufacturing Line |

3 | Bangladesh 2t/h Industrial Spaghetti Making Machine |

2021 Automatic Spaghetti Process Line customer with factory | |

1 | Bangladesh 2t/h Industrial Spaghetti Making Machine |

2 | 800kg/h Industrial Spaghetti Production Line For Sale In Nigeria |

3 | Algerian Spaghetti 300kg/h Production Line |