Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line

As a bread crumb production line manufacturer with many years of experience, our bread crumb making machine has a good manufacturing process. Bread crumb production line uses rice flour and corn flour as raw materials to make the bread crumbs delicious.Panko bread crumb maker machine professional breadcrumb maker line uses rice flour and corn flour as raw materials to make the bread crumbs delicious.The long and slivershaped breadcrumbs are of porous structure inside. After frying, the crumbs become straight up bit by bit. They are not only puffed and nice in appearance but also crisp and delicate in taste.

Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 100 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line Detail Introduction :

Introduction of Bread Crumb Maker Machines

Bread crumbs is mainly used for fried beefsteak and drumstick as frying dressing. As a bread crumb production line manufacturer with many years of experience, our panko bread crumb maker machine professional breadcrumb maker line has a good manufacturing process.

Panko bread crumb maker machine professional breadcrumb maker line uses rice flour and corn flour as raw materials to make the bread crumbs delicious.The long and slivershaped breadcrumbs are of porous structure inside. After frying, the crumbs become straight up bit by bit. They are not only puffed and nice in appearance but also crisp and delicate in taste.

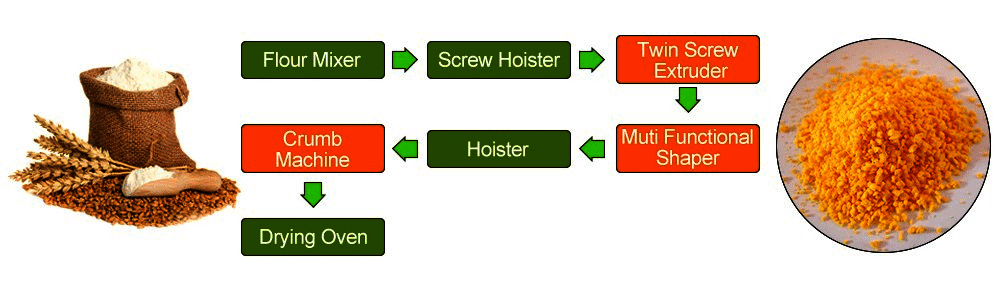

How to Produce Bread Crumb?

Panko bread crumb maker machine professional breadcrumb maker line is researched and developed on the basis of international advanced technology. The performance and quality have reached the highest domestic level of the same line. Bread Crumbs process line changes the traditional process. From mixing materials, extruding, cutting, drying to finished products are done in one automatic line. The Extruded Bread Crumbs are light and crispy with innovative shapes (small rings, crescent, small stars, balls, granule etc). They are widely used as food coating additives on the surface of frying food like: fried chicken, burger patty, sea foods (shrimp, fish), onion ring etc to obtain a very crispy and savory texture as well as unique and attractive fried foods’ golden color presentation.

Our technician team can design the layout of panko bread crumb maker machine professional breadcrumb maker line according to your factory size.

Flow Chart Of Commercial Bread Crumb Production Equipment

Flour Mixer-Screw Hoister -Twin Screw Extruder- Muti Functional Shaper- Hoister- Crumb Machine-Drying Oven

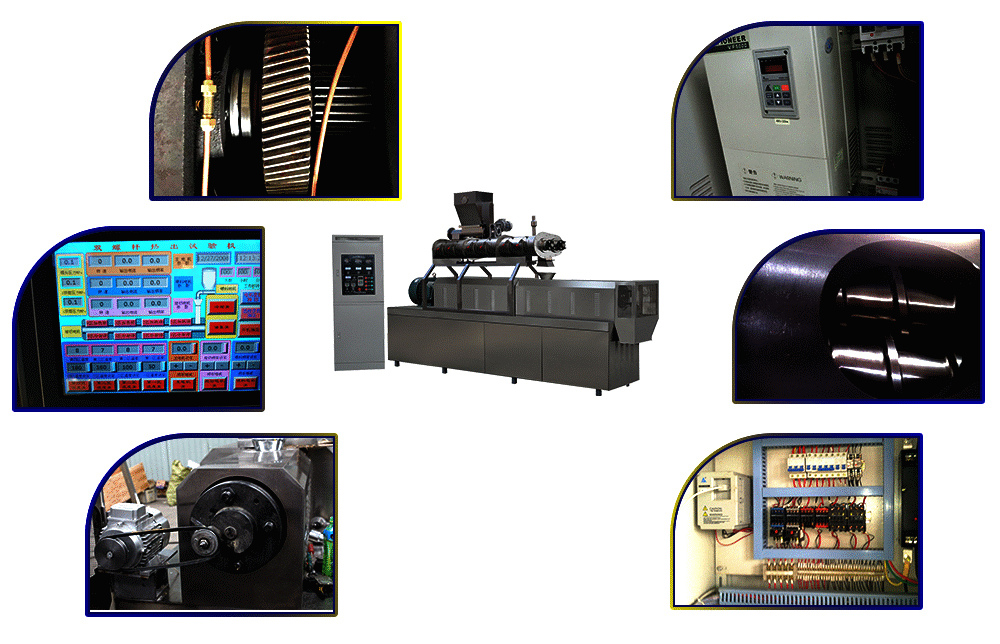

| Features of Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line | ||

| No. | Name | Features of Bread Crumb Making Machine |

| 1 | Flour Mixer | The raw material adding to water and liquid chemical additive fully mixing in it.This part that touches mixer to material adopts the stainless steel material. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials. |

| 2 | Screw Hoister | The mixed materials can be conveyed through it to the extruder feeder without any leaking, dusting and pollution; Feed quantity and speed is even and stable. |

| 3 | Twin Screw Extruder | Series of double-screw extruder mainly consist of feeding system, extruding system, cutting system, heating system, lubricating system and controlling system. |

| Automatic lubricating and forced cooling make sure that extruder performs safely and extends using life. | ||

| 4 | Muti Functional Shaper | The cutting machine divides the long products into standard length products, and the automatic feeding device at the front of the cutting machine arranges multiple long bars in a row. Knife cutting, cutting speed and traction speed are controlled by frequency conversion. Product compaction thickness is adjustable. |

| 5 | Hoister | Conveys the food from the low to high, according to the craft; decide the hoister height and the level distance. |

| 6 | Crumb Machine | Make the flakes into different shapes .we change the shape of machine to do the different sizes products .it have differet capacity |

| 7 | Drying Oven | Drying machine is a continuous production of drying equipment, it can use multilayers stainless steel mesh belt to achieve the material ’s feeding,transporting and discharging. It is used for continuous drying and cooling of agricultural products, medical herbs, pellets snacks, pastes, pet food or others. It can be used to bake and dry the food. The oven can bake all kinds of the inflating food, pet food, TVP/TSP food, peanut, nut, chew nut and so on. |

Specifications Of Bread Crumbs Extruder Machine Motor

| Specifications Of Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line Motor | |

| Attribute | Value |

| Power Rating | 0.18 KW |

| Efficiency Class | IE2 |

| AC Motor Type | Induction |

| Supply Voltage | 415 V ac |

| Phase | 3 |

| Output Speed | 1380 rpm @ 380 V |

| Number of Poles | 4 |

| Mounting Type | Foot |

| Rotation | Reversible |

| Maximum Output Torque | 1.25 Nm |

| Series | 3GAA |

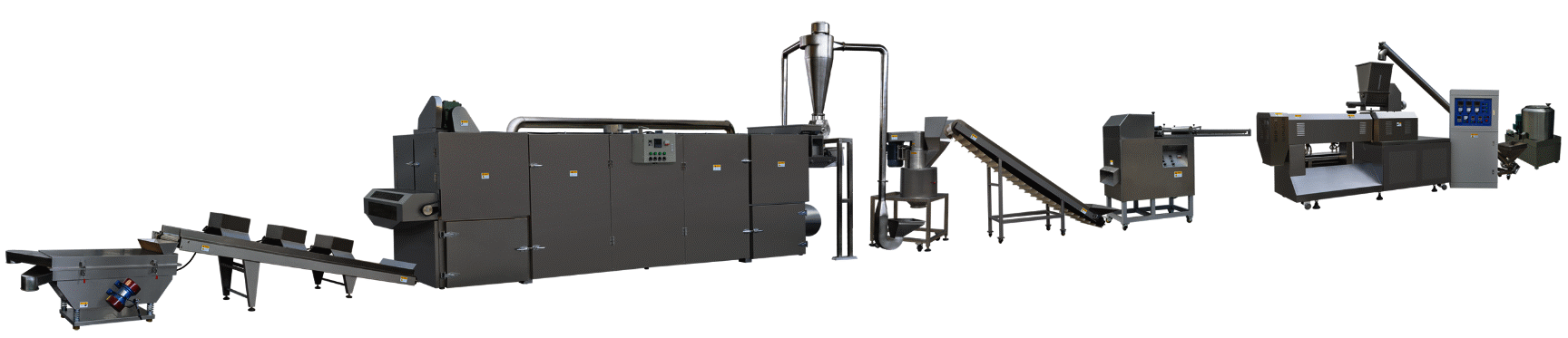

Technical Parameters of Commercial Bread Crumb Production Equipment :

Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line has 3 capacity:150kg/h and 250kg/h and 500kg/h,followed are technical parameters, you can choose them according to your requirements.

| Technical Parameters of Commercial Bread Crumb Production Machine | |||

| Model | LY-65 Bread Crumbs Processing Machinery | LY-70 Bread Crumbs Processing Machinery | LY-85 Bread Crumbs Processing Machinery |

| Installed capacity | 80KVA | 113KVA | 190KVA |

| Output | 150kg/h | 250kg/h | 500-600kg/h |

| Dimension | 21.8×2×2m | 25×2×2m | 30×2×2m |

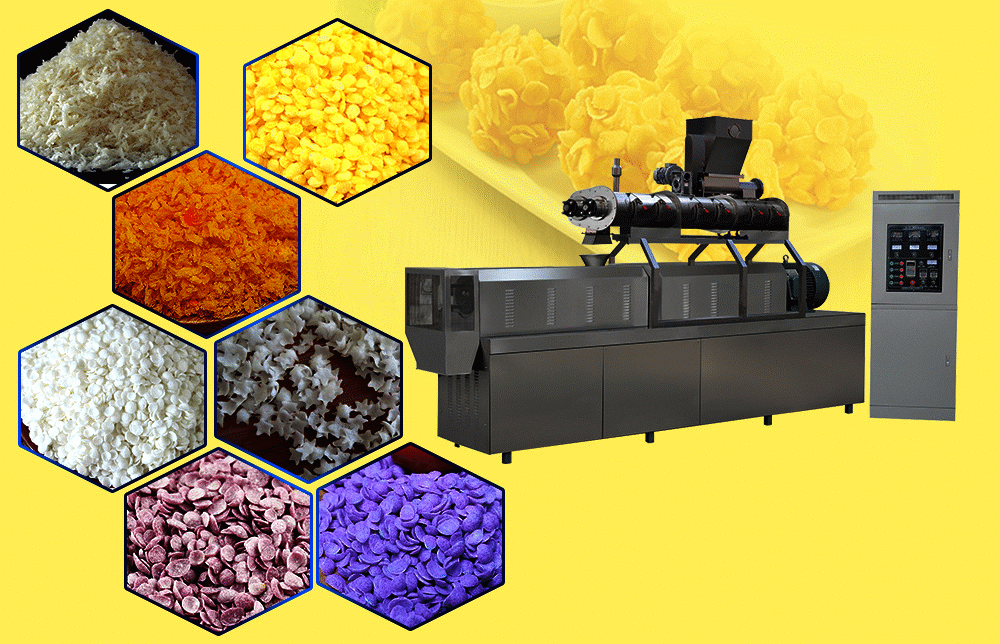

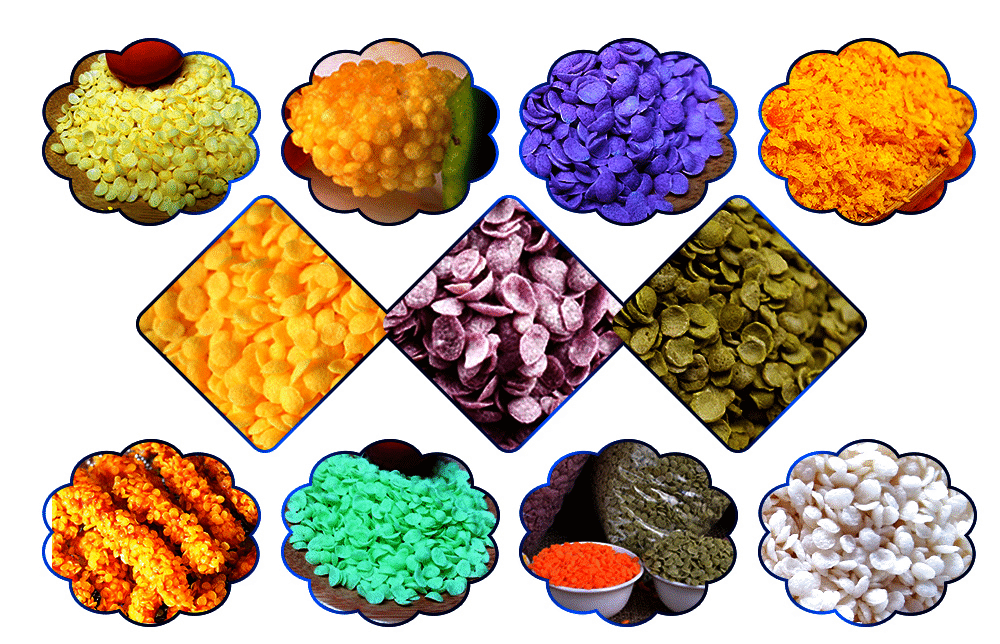

Pictures of Bread Crumbs Samples:

Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line can produce different shape and size bread crumbs by changing the crusher sieve.

2021 Customer Order of Panko Bread Crumb Maker Machine Professional Breadcrumb Maker Line Form:

| Customers Who Understand Bread Crumbs Production Line Processing Technology | |

| 1 | Bread Crumbs Production Line For Sale In Afghanistan |

| 2 | China Fully Automatic Bread Crumbs Production Line For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Bread Crumbs Production Line For Sale In Comoros |

| 4 | Bread Crumbs Production Line For Sale In Afghanistan |

| 5 | Bread Crumbs Production Line For Sale In Argentina |

| Dealed Customers Who Purchase Big Output Bread Crumbs Making Machine In 2021 | |

| 1 | Customized Bread Crumbs Making Machine For Sale In Congo |

| 2 | 800kg/h Bread Crumbs Making Machine For Sale In Denmark |

| 3 | 1000kg/h Bread Crumbs Making Machine For Sale In Congo |

| 4 | Customized High Efficiency Bread Crumbs Making Machine For Sale In India |

| 5 | 1000kg/h Bread Crumbs Making Machine For Sale In Denmark |

| Dealed Customer Have Plant Of Bread Crumbs Making Machine In 2021 | |

| 1 | Bread Crumbs Making Machine For Sale In Fiji |

| 2 | High Efficiency Bread Crumbs Making Machine For Sale In Fiji |

| 3 | High Efficient Industrial Bread Crumbs Production Line For Sale In Germany |

| 4 | Bread Crumbs Production Line For Sale In Germany |

| 5 | Industrial Bread Crumbs Production Line For Sale In Fiji |

| Dealed Customer Whose Intruduction Of Old Customer Of Bread Crumbs Production Line In 2021 | |

| 1 | Stainless Steel Bread Crumbs Production Line For Sale In Laos |

| 2 | Stainless Steel Bread Crumbs Production Line For Sale In Lebanon |

| 3 | Bread Crumbs Production Line For Sale In Lesotho |

| 4 | Automatic Stainless Steel Bread Crumbs Production Line For Sale In Mali |

| 5 | Fully Automatic Stainless Steel Bread Crumbs Production Line For Sale In Nauru |