Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw

As a professional extruded soy nuggets making machine supplier, our industrial soya protein food production line design good manufacturing process. Texture soya protein food making machinery can take Soya flour, defatted soya flour, peanut meal, and others as raw materials, to make the textured soya protein, vegetarian soya meat, soya badi, soya chunks , suya burgers for sales. Soya protein making machine extruded soya nuggets production line 55-110kw is a new kind of inflating processing line, which is produced and developed according to rich experiences and the requirement of food market. Full automatic Soya Nuggets production line processes low temperature soya meal, peanut meal, wheat gluten and isolate soy powder as raw material to make meat-like food with high protein content.

Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Warranty | 1 YEAR |

| Raw materials | soybean meal,peanut meal ect |

| Machines Materials | stainless steel |

| Automation | Fully Automatic |

| Baking fuel | Electric,gas,diesel,LPG |

| Products | Soybean protein,soya nuggets,vegetable meat |

| Trial Demonstration | Welcome You To Visit Us At Any Time For Machinery Demonstration |

Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw Detail Introduction :

Soya protein making machine extruded soya nuggets production line 55-110kw is a new kind of inflating processing line, which is produced and developed according to rich experiences and the requirement of food market. Full automatic Soya Nuggets production line processes low temperature soya meal, peanut meal, wheat gluten and isolate soy powder as raw material to make meat-like food with high protein content. Through feeding materials, extruding, cutting, drying, packing,the finished products are done once time fully automatically. And by changing the cutters, it can produce different kinds of shapes of soya food to meet customer requirements.

Details Description of Soya Protein Making Machine Extruded Soy Nuggets Production Line 55-110kw

| Details of Soya Nuggets Production Line | ||

| No. | Item | Details of Soya Nuggets Production Line |

| 1 | Raw materials of soya nuggets | Defatted soya meal, isolated soya protein,low temperature soya meal, peanut meal, wheat gluten and isolate soy powder, and additives, etc. |

| 2 | Capacity | 100-150kg/h, 120-160kg/h, 200-300kg/h, 300-400kg/h, 400-500kg/h, 1000kg/h, etc. |

| 3 | Consumption | Low electricity and labor consumption. |

| 4 | Power | 55-110kw |

| 5 | Machine materials | Stainless steel |

| 6 | Final products | Soya nuggets, soya chunks, soya pieces, soybean fibers |

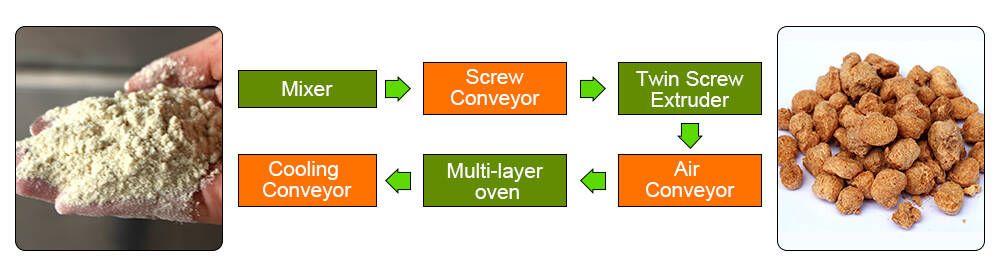

How To Make Soya Protein Food By Using Soya Meat Making Machine Extruded Soy Nuggets Production Line?

Mixer-Screw Conveyor-Twin Screw Extruder- Air Conveyor- Dryer- Hoister- Flavoring Machine

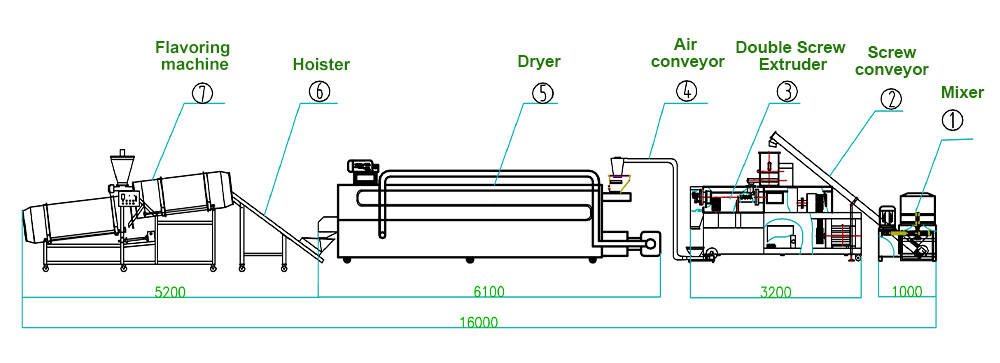

Machine Design Of Soya Nuggets Production Line

We can design the whole processing line according to customers' requirement (factory size and structure).

Machine List And The Functions Of The Automatic Extruded Soya Nuggets Production Line

| Equipment List of Soya Nuggets Production Line | ||

| No. | Machine name | Functions description of Soya Nuggets Production Line |

| 1 | Mixer | To mix defeated soya bean powder, seal meal with liquid, like water. |

| 2 | Screw conveyor | The feeding hopper is linked with the discharge port of the powder mixer, and the motor drives the screw feeding into the feeding machine of the extruder. |

| 3 | Inflating machine | To cook the soya bean powder and extrude in different shapes and sizes. |

| 4 | Air conveyor | Take the extruded products into drying machine. |

| 5 | Dryer | Drying extruded products, and reduce the moisture of extruded protein soya chunks. |

| 6 | Hoister | To convey the soya food into the next machine |

| 7 | Flavoring machine | According to customer requirements, cooled extruded soya nuggets can has different tastes. |

Technical Parameter Of Full Automatic Soya Protein Making Machine

| Technicial Parameter of Soyabean Meat Making Machine | |||

| Model | Extruder Power | Output | Extruder Dimension |

| LY65-TVP | 45 kw | 100~150kg/h | 3600x1000x2000mm |

| LY 65 | 45kw | 120~160kg/h | 3200×1000×1800mm |

| LY 75-TL | 140 kw | 200~300kg/h | 5200x1000x1900mm |

| LY 75-E | 125 kw | 400~500kg/h | 5900x1000x1900mm |

| LY 85-V | 110 kw | 300-400 kg/h | 5900x1000x1900mm |

What Is The Features Of Full Automatic Extruded Soy Nuggets Production Line?

Simple structure in linear type, easy in installation and maintain.

Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

High pressure double crank to control the die opening and closing.

Running in a high automation and intellectualism, no pollution

Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

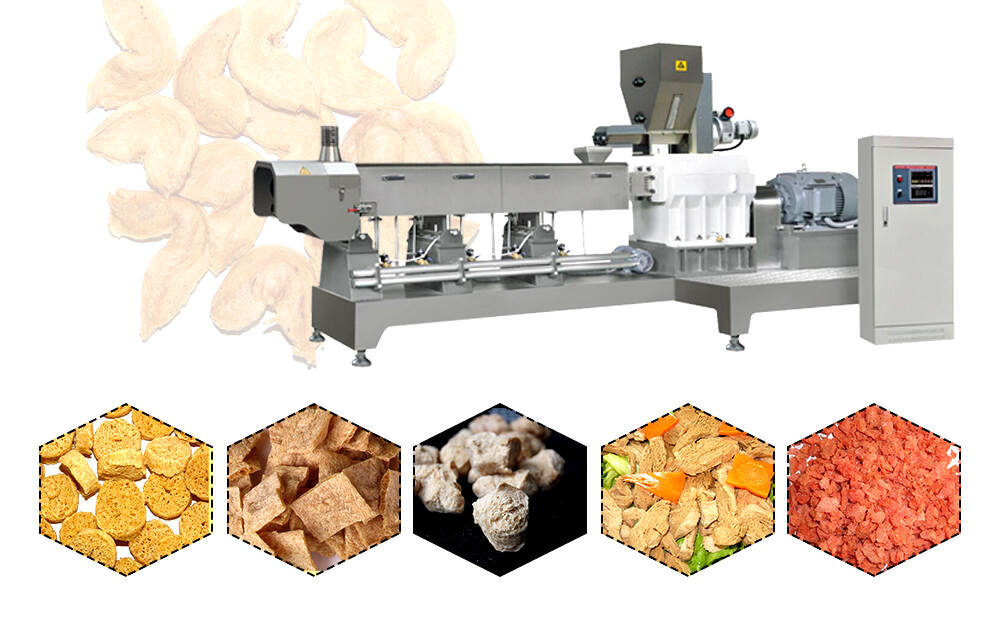

Machine Details Photos Of Soya Bean Meat Protein Food Production Line

Double screw extruder ---- the main machine to make soya protein food. It is used to extrude and inflate material and then form it into different shapes. According to different screw design rate to full different technology request.

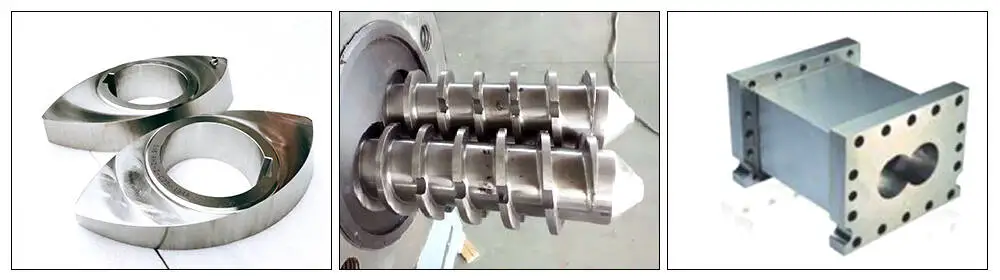

Equipment Materials

1. All the soya protein food making machine are made by stainless steel

2. Screws : alloy steel (38CrMoAl)

3. The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

4. The extrusion barrel is constructed of carbon steel, is made by 45 steel, stainless steel coating.

5. The gearbox has automatic lubrication function, with extends gear life.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

7. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

8. World famous brand Siemens main motor (like Siemens,ABB motor) , guaranteeing good quality.

Soya Protein Food Samples Show

Final food can be:

Dry textured soya protein pellets, crumbs, minced, flakes, chunks, chips ,schnitzel, nuggets.

High moisture wet protein soya, pea, pea-sunflower.

Applications Of Soya Protein Food Produced By Automatic Soya Bean Meat Protein Production Line

| Application of Soyabean Meat Making Machine | |

| 1 | The full automatic soya nuggets production line takes soybean meal and peanut meal, etc as main raw materials. After the processing of mixing, extruding and cutting, the soya meal can become the layer fiber structure. After the soya protein food is extruded from the dies of extruder plant, the food can be sliced into different shapes (like granules, flakes, chunks, nuggets, goulash, etc) and different size. |

| 2 | Also Extruded Soya Protein Machine can produce the product with high nutrition, the meaty state and taste. |

| 3 | The final soya products with the features of high nutrition, the finished products look and taste like meat, absorb oil and water easily, no cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deep freeze food production and all kinds of vegetarian snacks and food. |

2021 Customer Order Soya Meat Production Line Forms:

| Dealed Customer Customers Who Have Not Worked In The Soya Meats Industry Before In 2021 | |

| 1 | China 300t/Year Soya Meats Manufacturing Technology |

| 2 | 1t/h Soya Meats Equipment For Sale In Indian |

| 3 | 1t/h Soya Meats Equipment For Sale In Bolivia |

| 4 | Senegal 1t/h Soya Meats Machine |

| 5 | 1t/h Soya Meats Machine For Sale In Côte d'Ivoire |

| Customers Who Understand Soya Meats Processing Technology | |

| 1 | 1t/h Soya Meat Machine Sold In Russia |

| 2 | 1t/h Soya Meat Brands For Sale In Uzbekistan |

| 3 | 1000kg/h Soya Meat Equipment For Sale In Senegal |

| 4 | Mozambique 1t/h Soya Meats Hot Machine |

| 5 | Bangladesh 2t/h Soya Meats Hot Machine |

| Dealed Customer Have Plant Of Soya Meats Production Line In 2021 | |

| 1 | 1t/h Soya Meat Brands Machine |

| 2 | Uzbekistan 1t/h Soya Meats Manufacturing Equipment |

| 3 | Usa 1t/h Soya Meats Manufacturing Equipment |

| 4 | 800kg/h Soya Meats Manufacturing Equipment For Sale In Nigeria |

| 5 | Algerian Soya Meats Hot Machine |

| Dealed Customers Who Low-Price Purchase Soya Meats Production Line In 2021 | |

| 1 | Sudan 200kg/h Soya Meats Production Line |

| 2 | Moldova Small 200kg/h Soya Meats Production Line |

| 3 | 200kg/h Soya Meats Production Line Sold In Ukraine |

| 4 | Nigeria 150kg/h Soya Meats Hot Machine |

| 5 | Austria Sells Industrial Soya Meat Production Line |