High Speed Dog Food Production Line Pet Dog Food Making Machine

One of the largest full automatic dog food production line manufacturers in China. our Loyal dog food extruder machine design good manufacturing process with great prices and high quality. Pet cat dog feed extruder processing line takes Rice flour, corn flour, wheat flour, soya flakes meal, wheat bran, fish powder, bone powder, fish meal and others as raw materials, to make the pet food for sales. High Speed Dog Food Production Line Pet Dog Food Making Machine is widely used in pet foods such as dogs, cats, floating fish feed and sinking fish feed. The full automatic dog food production line has reasonable design, high degree of automation, stable performance, simple operation, durability and high production efficiency.

High Speed Dog Food Production Line Pet Dog Food Making Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Model Number | LY65, LY70, LY 85 |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Certification | CE BV ISO 9001 |

| Material | Stainless Steel 304 |

| Warranty | 1 YEAR |

| Trial Demonstration | Welcome You To Visit Us At Any Time For Machinery Demonstration |

| MOQ | 1 set/Pet Food Extruder Machine |

| Voltage | 220v/380v/50Hz |

High Speed Dog Food Production Line Pet Dog Food Making Machine Detail Introduction :

The full automatic dog food production line uses the high temperature heating and high pressure of a twin-screw extruder to add different raw materials and nutrients to form the final pet food. The dog food production line is widely used in pet foods such as dogs, cats, floating fish feed and sinking fish feed. The design of the production line is novel and unique, the pet food produced is delicate and unique in taste, different in shape, scientific in nutrition ratio and easy to digest. The pet food machine has been widely recognized by customers.

The Pet Food Production Line is a comprehensive solution designed to meet the growing demand for high-quality, nutritious, and varied pet food. Catering to both small-scale boutique brands and large-scale industrial producers, this production line is engineered to produce a wide range of pet food types, including dry kibble, wet food, treats, and specialty diets for pets of all sizes and breeds.

A pet food production line is a highly specialized setup designed to manufacture various types of pet food, including dry kibble, wet food, treats, and more. These lines are engineered to ensure high standards of quality and nutritional value, meeting the diverse dietary needs of pets.

Product Advantages

This state-of-the-art dog food making machine is engineered for versatility and performance, capable of handling various ingredients to produce premium dog food that meets the nutritional requirements of dogs of all breeds and ages. From mixing and extruding to drying and packaging, this production line streamlines every step of the manufacturing process, enabling producers to maximize output while maintaining the highest standards of product quality.

High Efficiency and Productivity: The High Speed Dog Food Production Line is optimized for high-volume production, capable of manufacturing large quantities of dog food quickly and consistently. This efficiency is crucial for meeting the demands of a competitive pet food market.

Versatility: With adjustable parameters and interchangeable dies, the production line can produce a variety of dog food types, from kibble to treats, in multiple shapes and sizes. This versatility enables manufacturers to diversify their product offerings and cater to specific dietary needs and preferences.

Consistent Quality: Precision control over every aspect of the production process ensures that each batch of dog food meets stringent quality standards. The extrusion process cooks the ingredients thoroughly, enhancing digestibility and nutrient availability while ensuring the elimination of pathogens.

Cost-Effectiveness: By optimizing raw material usage and streamlining the production process, the production line minimizes waste and reduces operational costs. The durability and low maintenance requirements of the machinery also contribute to long-term savings.

Safety and Hygiene: Constructed with food-grade materials and designed for easy cleaning and sanitation, the production line adheres to the highest standards of food safety and hygiene. This commitment to quality protects both the end consumer and the manufacturer's brand reputation.

Ease of Operation: The production line is designed with user-friendliness in mind, featuring intuitive controls and automation options that reduce the need for manual intervention and simplify the manufacturing process.

The High Speed Dog Food Production Line Pet Dog Food Making Machine is a comprehensive solution for pet food manufacturers seeking to capitalize on the growing demand for high-quality dog food. Its combination of efficiency, versatility, quality control, and cost-effectiveness makes it an invaluable asset in the competitive pet food industry, enabling manufacturers to produce safe, nutritious, and appealing dog food products that meet both pet and owner satisfaction.

The Description Of The HIGH SPEED DOG FOOD PRODUCTION LINE PET DOG FOOD MAKING MACHINE

1. Ingredients: corn, soya, bean meal, vegetables, bone meal, meat meat etc.

2. Products: Pet Food, Like Dog, Cat, Fish, Bird Food etc. with different shapes and tastes by changing the dies and formulations.

3. Capacity: 120-200 KG/H,300-500 KG/H,800-1000 KG/H,1-2T//H,2-3T/H,3-5T/H, etc.

4.Voltage:Three phases:380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage according to different countries.

5. Machines Materials: All the machines are made by food grade stainless steel.

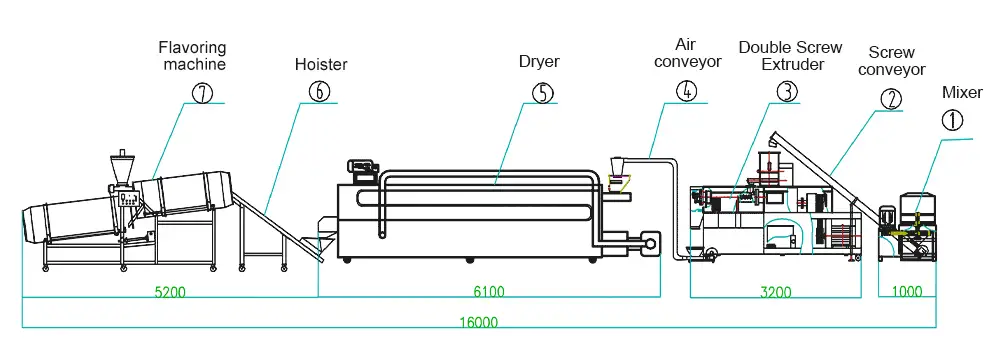

FLOW CHART OF HIGH SPEED DOG FOOD PRODUCTION LINE PET DOG FOOD MAKING MACHINE

Mixer -- Screw Conveyor -- Double Screw Extrude -- Air Conveyor -- Dryer -- Hoister -- Flavoring Machine

The dog food production line has reasonable design, high degree of automation, stable performance, simple operation, durability and high production efficiency.

TECHNICAL PARAMETERS OF HIGH SPEED DOG FOOD PRODUCTION LINE PET DOG FOOD MAKING MACHINE

DIFFERENT MODEL OF PET HIGH SPEED DOG FOOD PRODUCTION LINE FOR SALE

Technical Parameter Of Full Automatic Dog Food Production Line | ||||

Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

PFE-65-1 | 80kw | 56kw | 120--150kg/h | 22500x1200x2200mm |

PFE-70-1 | 128kw | 90kw | 200-250kg/h | 25000x1500x2200mm |

PFE-85-1 | 175kw | 123kw | 300-600kg/h | 30000x3500x4300mm |

PFE-90-1 | 287kw | 216kw | 1000-1200kg/h | 40000x2400x4000mm |

PFE-75-2 | 186kw | 139.5kw | 300-600kg/h | 24000*2000*2800mm |

PFE-95-2 | 383kw | 287kw | 1000-1500kg/h | 40000*3000*4000mm |

Advantages of processor process

The Advantages Of The Industrial Pet Dog Food Making Processing Line | |

| Extruder Process Running Fast | Pet food making machine continuous running, high quantity capacity, can meet strict production deadlines. |

| Different Textures And Colors | Variable density, air and moisture content, chewiness, crispiness, etc. It can produce pet treats food like strip shape, stick shape, twisted stick shape, double colors and multi-colors core filled snack. |

| Efficient | The extrusion continuous processing is low in cost, precise process control and automation reduces waste and boost, easy cleaning and maintenance. |

| Consistent | Pet dog making machine and cutting produces a very uniform end product of constant cross section and size. The process is extremely controllable and reliable, allowing high quality to be maintained throughout. |

| Automation Control | Automation control to ensure consistent quality and product features. |

| Nutrition receipt | Pets can absorb nutrition elements during enjoy chewing these delicious snacks.Automatic pet food making machines not only provides nutrition to dogs, like protein, fat, vitamin, etc, but also satisfies the pet nature hobby, benefits its strong teeth, cleans mouth and teeth, and prevents disease. |

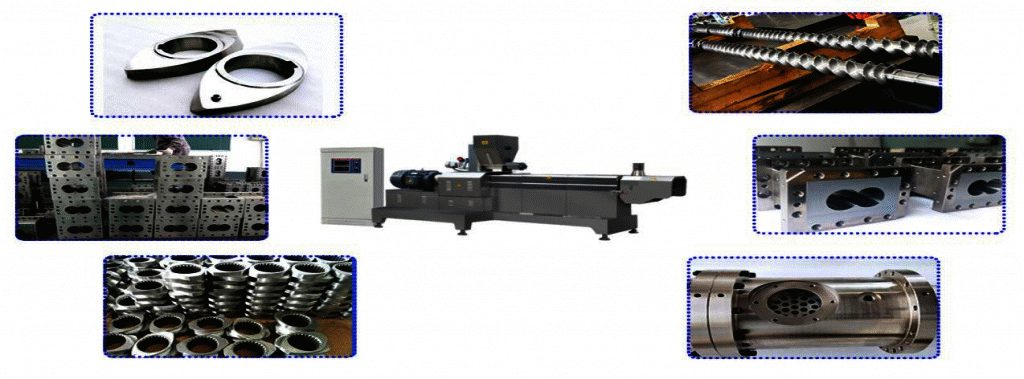

DETAILED MAIN EQUIPMENT PICTURE OF HIGH SPEED DOG FOOD PRODUCTION LINE

The dog food production line is made of food-grade stainless steel. The entire production line has a very high quality, is not easy to be damaged, has a long time of use, is easy to maintain, and has high production efficiency and production quality. The cost performance is also very high. The pet food machine has been exported to many Countries and regions.

Equipment material:

1. All pet food machine are made of food grade stainless steel.

2. Screw: alloy steel (38CrMoAl).

3. HRC hardness is around 60 --- 62, with good self-cleaning ability, no need to unload or clean the barrel and screw when baking or changing materials.

4. The extrusion cylinder is made of carbon steel, made of 45 steel, stainless steel coating.

5. The gearbox has an automatic lubrication function, which can extend the life of the gear.

6. The cutter is fixed on the die head base and rotates through the V-belt drive.

RAW MATERIALS

The automatic dog food production line uses grain meal, soybean meal, meat meal, fish meal, bone meal, rice bran, milk powder, etc. as raw materials. Double screw pet food extruder can use different ingredients into pet food formulations: wheat flour, corn flour, corn grits, soy meal, fresh meat, bone powder or fish flour. and also can also include additives such as animal and vegetable fat and minerals, amino acids and vitamins and flavor enhancers.The advanced extrusion concept the latest technology for production in the aquatic feed and pet food industries

APPLICATIONS OF HIGH SPEED DOG FOOD PRODUCTION LINE PET DOG FOOD MAKING MACHINE

The full automatic pet food processing line can be applied to cats, dogs, foxes, monkeys, pigs, sheep, rabbits, fish, shrimps, poultry, birds, etc. The pet food machine can adjust the process parameters of raw materials, temperature, moisture, etc. The size and shape of pet food can be adjusted by changing the mould and cutting speed. Different raw material and nutrient elements can be added together according to advanced formula, so the final products are tasty and easy to digest. It can adjust the pet feed machine according to customers’ requirement.

What Kind of Of Pet Dog Food Production Line Has Been Loyal Sold In 2021 ?

Customer Case Of Full Automatic Pet Dog Food Processing Line With The Cheapest Price In 2021 | |

| 1 | 2T/H Muti-Function Pet Dog Food Production Line For Sale Senegal Suppliers |

| 2 | 800-1000kg/h Dog Food Machine Manufacturing Process Plant For Sale Nigeria Factory Plant |

| 3 | 100-150Kg/H Pet Dog Chewing Food Manufacturing Process Equipment For Sale Burkina Faso Processing |

| 4 | 250Kg/H Automatic Dog Food Processing Plant Process Machine For Sale Botswana Agent |

| 5 | 100-150kg/h Dog Treat Food Maker Machine For Sale Philippines Customer Factory Plant |

| 6 | LY-75 Industrial Pet Cat Food Machine For Sale Pakistan |

| 7 | 300-500kg/h Chewy Pet Food Process Production Line For Sale Mozambique |

Transaction Case Of The Commercial Pet Dog Food Making Machine With High Quality Manufacturer In 2021 | |

| 1 | 200-250kg/h Commercial Dog Food Manufacturers Food Production Line For Sale Austrian Agent |

| 2 | LY65 Capacity Dog Treat Production Lien Process Machine For Sale To Moldova Factory |

| 3 | 100-150kg/h Fish Feed Processing Equipment For Sale Ukraine |

| 4 | LY-85 Small Electric Animal Feed Dog Treat Process Manufacturing Machine For Sale Singapore |

| 5 | 800-1200kg/h Pet Dog Food Manufacturing Process Extruder For Sale Puerto Rico |

High Quality Trader Customer Case Of The Industrial Dry Pet Food Equipment Processing Line Price In 2021 | |

| 1 | 500kg/h Manufacturing Process Of Pet Dog Food For Sale Bolivia Agent |

| 2 | 700kg/H Dog Food Processing Equipment Cost Price For Sale Dominica |

| 3 | 300kg/h Dog Cat Food Making Manufacturing Processing Line In Senegal Manufacturers |

| 4 | 100-150Kg/H Pet Food Extruder Process Line Price In Nigeria |

| 5 | 200-250kg/h Pet Food Processing Equipment Factory For Sale Cote d'Ivoire |

| 6 | LY-75 Testing Machine For Dog Food Making Machine Cost For Sale Cameroon |

| 7 | LY-70 Industrial Pet Treat Food Making Equipment For Sale South Africa Pet Food Suppliers |

Customer Case Of The Dog Food Manufacturing Equipment With The Farm Setting In 2021 | |

| 1 | 200-250kg/h Pet Food Manufacturing Equipment For Sale Thailand Agent |

| 2 | Uzbekistan 100kg/h Dog Food Processing Plant For Sale (Tashkent) |

| 3 | 800kg/H Extruded Animal Food Processing Machine For Sale Australian Pet Food Machinery Manufacturers |

| 4 | 1000kg/H Pet Food Making Machine Manufacturing Process For Brazil |

- What are the primary advantages of using a high-speed dog food production line compared to traditional manufacturing methods?

- How does the extrusion process in a dog food making machine affect the nutritional value of the finished product?

- Can the high-speed dog food production line handle different formulations and ingredient types without significant downtime for cleaning and setup?

- What kind of quality control measures are typically in place on a high-speed dog food production line?

- How energy-efficient are high-speed dog food production lines, and what measures can be taken to minimize their environmental impact?

- What are the typical maintenance requirements for a high-speed dog food production line, and how frequently should maintenance be performed?

- Are there any specific training programs recommended for operators of high-speed dog food making machines to ensure optimal performance?

- What safety protocols need to be established to protect workers operating a high-speed dog food production line?

- How scalable is a high-speed dog food production line if a company needs to increase production capacity in the future?

- What are the biggest challenges faced by manufacturers when integrating a new high-speed dog food production line into their existing operations?

How does a pet food production line work?

The process starts with the preparation and mixing of ingredients according to specific recipes. These ingredients may include meats, grains, vitamins, and minerals. The mixture is then cooked and extruded through a machine that shapes it into various forms, such as kibbles for dogs or pellets for cats. The shaped food is then dried, cooled, and packaged.

What types of pet food can be produced on a production line?

A pet food production line can produce a variety of pet food types, including dry kibble, wet food, treats, and special diet foods. The versatility of the line depends on the equipment and the formulations used.

What safety standards are applied to pet food production lines?

Pet food production lines must adhere to strict safety and quality standards to ensure the food is safe for pet consumption. This includes regulations set by governmental agencies such as the FDA in the United States, which require that pet food be produced under sanitary conditions and be free of harmful substances.

COMPANY INTRODUCTION

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

Our service

The Services Of Loyal Industrial Company | |

High-quality after-sales service | Engineer services for overseas machinery services |

| 1. The distribution map requested by the buyer will be provided. 2. Process operation manual will be provided after delivery. 3. Provide 1 year complete warranty and lifetime maintenance services. 4. Free fragile spare parts will be sent out with the packing box. 5.The first installation can be completed by the equipped engineer. | 1. Provide free consultation service before, during and after sale. 2. Free project planning and design services. 3. Free debugging of equipment until everything is normal. 4. Free equipment maintenance and personal operation training. 5. Provide free new production process and formula. |